Bi2O3/(BiO)2CO3 heterojunction catalyst with visible photocatalytic activity and preparation method for Bi2O3/(BiO)2CO3 heterojunction catalyst

A catalytic activity, visible light technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve problems such as catalytic activity limitation, achieve good photocatalytic performance, Simple operation and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: 2.3 mmol of bismuth nitrate pentahydrate and 3.0 mmol of urea were mixed and dissolved in 30 ml of deionized water, and stirred at room temperature for 30 min to form a precursor solution.

[0030] Step2: Transfer the precursor solution obtained in Step1 to a polytetrafluoroethylene-lined autoclave, keep it at 160°C for 12 hours, and cool to room temperature with the furnace.

[0031] Step3: Wash the powder obtained in Step2 with deionized water and absolute ethanol in sequence, and then vacuum-dry at 80°C to obtain (BiO) 2 CO 3 powder.

[0032] Step4: Get the (BiO) obtained in Step3 2 CO 3 The powder is calcined at 400°C for 60 minutes to obtain Bi with visible photocatalytic activity. 2 o 3 / (BiO) 2 CO 3heterojunction catalysts.

[0033] Step5: For comparison and description, take the (BiO) obtained in Step3 2 CO 3 The powder was calcined at 500°C for 4h, and the obtained sample was pure phase Bi 2 o 3 Powder.

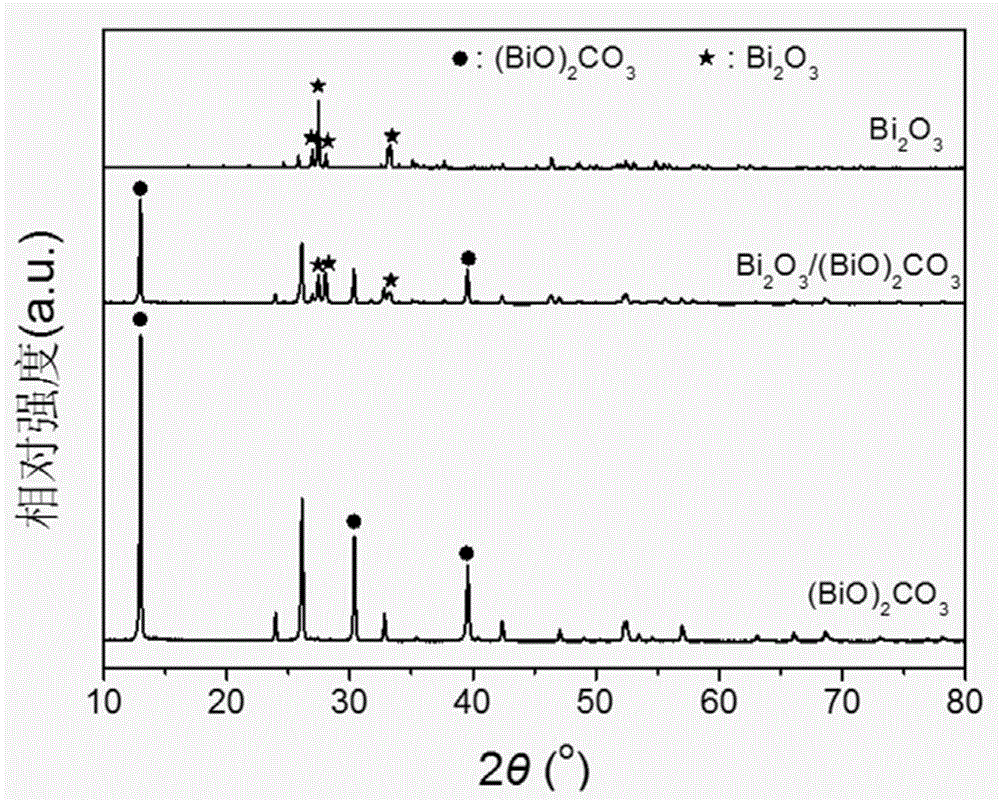

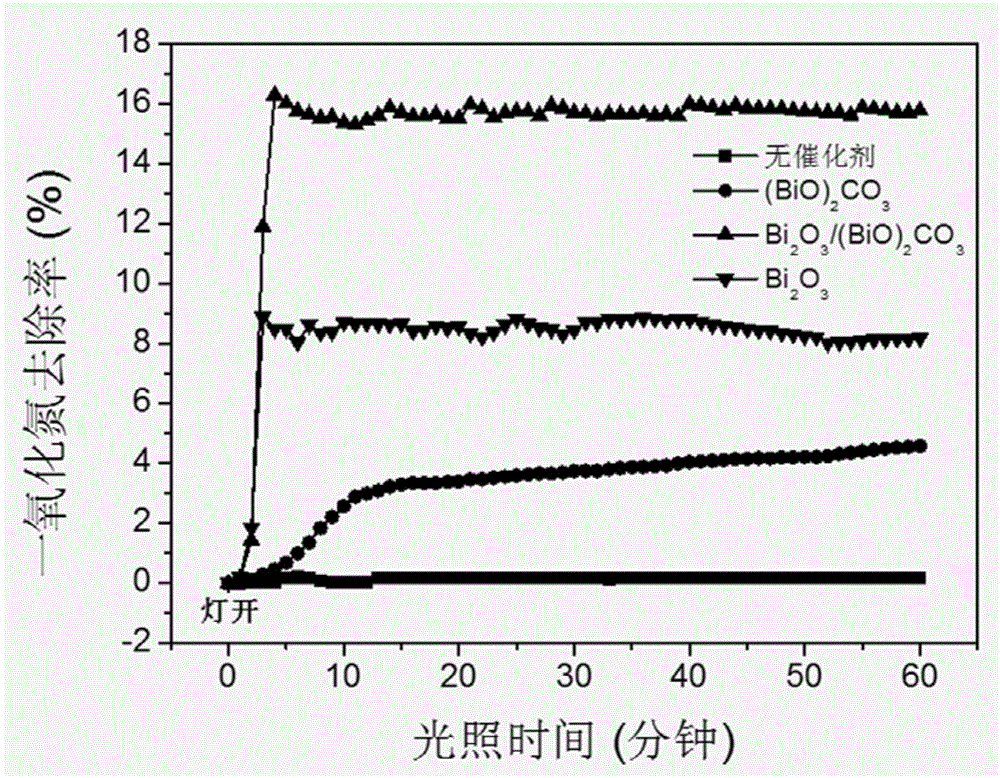

[0034] Right (BiO) 2 CO 3 Powder,...

Embodiment 2

[0043] Step1: Mix and dissolve 2.5mmol of bismuth citrate and 3.1mmol of urea in 30ml of deionized water, add 10ml of concentrated ammonia water dropwise with stirring at room temperature, and then stir at room temperature for 30min to form a precursor solution.

[0044] Step2: Transfer the precursor solution obtained in Step1 to a polytetrafluoroethylene-lined autoclave, keep it at 180°C for 24 hours, and cool to room temperature with the furnace.

[0045] Step3: Wash the powder obtained in Step2 with deionized water and absolute ethanol in sequence, and then vacuum-dry at 80°C to obtain (BiO) 2 CO 3 powder.

[0046] Step4: Get the (BiO) obtained in Step3 2 CO 3 The powder is calcined at 400°C for 60 minutes to obtain Bi with visible photocatalytic activity. 2 o 3 / (BiO) 2 CO 3 heterojunction catalysts.

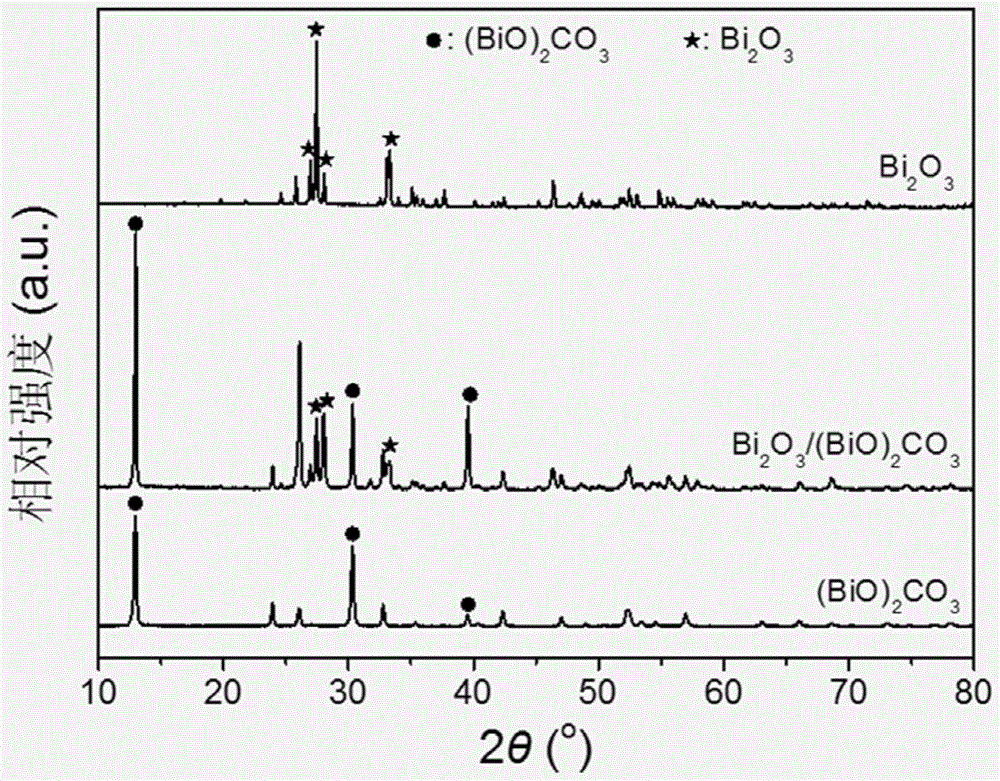

[0047] For the sample Bi obtained in Step4 2 o 3 / (BiO) 2 CO 3 The heterojunction was tested by XRD. Test pattern such as image 3 shown. image 3 It shows th...

Embodiment 3

[0050] Step 1: 2.3 mmol of bismuth nitrate pentahydrate and 3.0 mmol of urea were mixed and dissolved in 30 ml of deionized water, and stirred at room temperature for 30 min to form a precursor solution.

[0051] Step2: Transfer the precursor solution obtained in Step1 to a polytetrafluoroethylene-lined autoclave, keep it at 160°C for 12 hours, and cool to room temperature with the furnace.

[0052] Step3: Wash the powder obtained in Step2 with deionized water and absolute ethanol in sequence, and then vacuum-dry at 80°C to obtain (BiO) 2 CO 3 powder.

[0053] Step4: Get the (BiO) obtained in Step3 2 CO 3 The powder was calcined at 400°C for 20 minutes to obtain Bi with visible photocatalytic activity. 2 o 3 / (BiO) 2 CO 3 heterojunction catalysts.

[0054] For the sample Bi obtained in Step4 2 o 3 / (BiO) 2 CO 3 The heterojunction was tested by XRD. Test pattern such as Figure 5 shown. Figure 5 It shows that the sample obtained in Step4 is indeed Bi 2 o 3 / (B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com