High-toughness Si3N4 ceramic preparation method

A high-toughness, -si3n4 technology, applied in the field of preparation of high-toughness Si3N4 ceramics, to achieve the effect of improving fracture toughness, excellent comprehensive mechanical properties, and improving fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

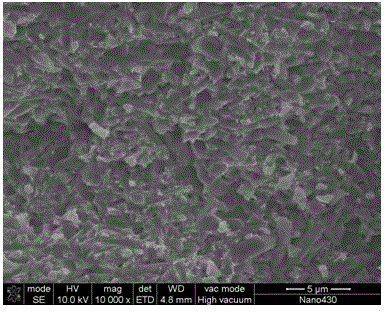

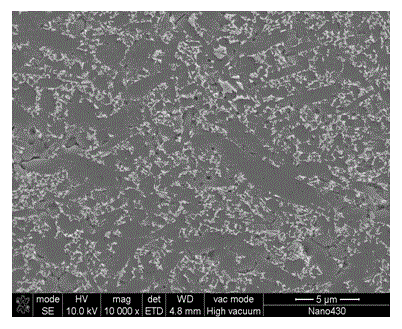

Image

Examples

Embodiment 1

[0032] The high toughness Si of the present invention 3 N 4 The preparation method of pottery, comprises the steps:

[0033] (1) with Si 3 N 4 Powder as raw material, with β-Si 3 N 4 as the seed crystal, with Re 2 o 3 is a sintering aid, in which β-Si 3 N 4 The seed crystal is self-made β-Si with specific morphology 3 N 4 Seed, its aspect ratio is 3.0-5.0, diameter is 0.30-0.60μm, Re=Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm , any of Yb, Lu, Si 3 N 4 Powder, β-Si 3 N 4 Seed and Re 2 o 3 The mass fraction ratio of is:

[0034] Si 3 N 4 Powder 75-98wt%

[0035] β-Si 3 N 4 Seed 1-10wt%

[0036] Re 2 o 3 1-15wt%

[0037] (2) Si 3 N 4 Powder, β-Si 3 N 4 Seed and Re 2 o 3 To mix:

[0038] (3) After drying and high-temperature hot-pressing sintering, Si with high toughness can be obtained. 3 N 4 ceramics.

[0039] In this example, Re=Lu, the preparation of high toughness Si 3 N 4 The specific method of ceramics is as follows:

...

Embodiment 2

[0044] In this example, Re=Lu, the preparation of high toughness Si 3 N 4 The specific method of ceramics is as follows:

[0045] β-Si with a self-made aspect ratio of 4.2 and a diameter of 0.44 μm 3 N 4 as the seed crystal, with Lu 2 o 3 (99.9% purity) is a sintering aid according to Si 3 N 4 Powder mass fraction is 75wt%, β-Si 3 N 4 The seed mass fraction is 10wt%, Lu 2 o 3 The mass fraction ratio is 15wt% to carry out batching, prepares Si according to embodiment 1 method 3 N 4 ceramics. The relative density of the prepared ceramic material is 97%, the Vickers hardness is 14.3GPa, and the fracture toughness measured by indentation method is 8.5MPa m 1 / 2 , The three-point bending strength is 685Mpa.

Embodiment 3

[0047] In this example, Re=Lu, the preparation of high toughness Si 3 N 4 The specific method of ceramics is as follows:

[0048] β-Si with a self-made aspect ratio of 4.2 and a diameter of 0.44 μm 3 N 4 as the seed crystal, with Lu 2 o 3 (99.9% purity) is a sintering aid according to Si 3 N 4 Powder mass fraction is 90wt%, β-Si 3 N 4 The seed mass fraction is 1wt%, Lu 2 o 3 The mass fraction ratio is 9wt% to carry out batching, prepares Si according to embodiment 1 method 3 N 4 ceramics. The relative density of the prepared ceramic material is 99%, the Vickers hardness is 17.3GPa, and the fracture toughness measured by indentation method is 8.7MPa m 1 / 2 , The three-point bending strength is 860Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com