Corrosion resistant PE water pipe

A water supply pipe, corrosion-resistant technology, applied in the field of pipes, can solve the problems of reducing the service life of PE water supply pipes, easy corrosion of PE water supply pipes, aggravating environmental pollution, etc., and achieves high toughness, strong corrosion resistance, and improved dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

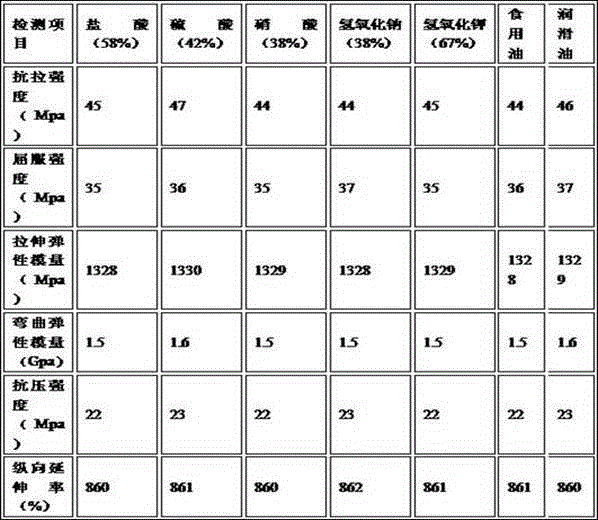

Examples

Embodiment 1

[0018] A corrosion-resistant PE water supply pipe, made of the following raw materials in weight percentage: polyethylene (HDPE) 98%, color masterbatch 0.2%, phthalate 0.1%, 2,6-di-tert-butyl-p-methyl Phenol (BHT) 0.3%, methyl thiopropionate 0.4%, azobiscarboxamide 0.2%, dioctyltin maleate 0.2%, tetrakis[β-(3,5-di-tert-butyl-4-hydroxybenzene base) propionate] pentaerythritol ester 0.4%, EVA 0.4%, clay nanocomposite 3%.

[0019] The preparation method of the above-mentioned corrosion-resistant PE water supply pipe comprises the following steps:

[0020] 1) Add polyethylene (HDPE), phthalate, 2,6-di-tert-butyl-p-cresol (BHT), methyl thiopropionate, azobiscarboxamide, EVA, clay according to the above weight percentage Put the seven raw materials of the nanocomposite into a mixing mixer, start stirring after heating to 95 degrees, continue stirring for 30 minutes, and then cool to 45 degrees to obtain the mixed material A, and set aside;

[0021] 2) Put the masterbatch, di-n-oct...

Embodiment 2

[0026] A corrosion-resistant PE water supply pipe, made of the following raw materials in weight percentage: polyethylene (HDPE) 94%, color masterbatch 0.8%, phthalate 0.6%, 2,6-di-tert-butyl p-methyl Phenol (BHT) 0.5%, methyl thiopropionate 0.7%, azobiscarboxamide 0.6%, dioctyltin maleate 0.5%, tetrakis[β-(3,5-di-tert-butyl-4-hydroxybenzene base) propionate] pentaerythritol ester 1.2%, EVA 1.1%, clay nanocomposite 1%.

[0027] The preparation method of the above-mentioned corrosion-resistant PE water supply pipe comprises the following steps:

[0028] 1) Add polyethylene (HDPE), phthalate, 2,6-di-tert-butyl-p-cresol (BHT), methyl thiopropionate, azobiscarboxamide, EVA, clay according to the above weight percentage Put the seven kinds of nanocomposite materials into the mixing mixer, start stirring after heating to 110 degrees, continue stirring for 15 minutes, and then cool to 45 degrees to obtain the mixed material A, set aside;

[0029] 2) Put the masterbatch, di-n-octylt...

Embodiment 3

[0034] A corrosion-resistant PE water supply pipe, made of the following raw materials in weight percentage: polyethylene (HDPE) 95.7%, color masterbatch 0.5%, phthalate 0.4%, 2,6-di-tert-butyl p-methyl Phenol (BHT) 0.5%, methyl thiopropionate 0.5%, azobiscarboxamide 0.4%, dioctyltin maleate 0.5%, tetrakis[β-(3,5-di-tert-butyl-4-hydroxybenzene base) propionic acid] pentaerythritol ester 1%, EVA 1%, clay nanocomposite 5%.

[0035] The preparation method of the above-mentioned corrosion-resistant PE water supply pipe comprises the following steps:

[0036] 1) Add polyethylene (HDPE), phthalate, 2,6-di-tert-butyl-p-cresol (BHT), methyl thiopropionate, azobiscarboxamide, EVA, clay according to the above weight percentage Put the seven raw materials of the nanocomposite into a mixing mixer, start stirring after heating to 100°C, continue stirring for 20 minutes, then cool to 45°C to obtain the mixed material A, and set aside;

[0037] 2) Put the masterbatch, di-n-octyltin maleate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com