Preparation method and application of intelligent anti-corrosion coating capable of being automatically repaired

An anti-corrosion coating and automatic repair technology, applied in anti-corrosion coatings, coatings, epoxy coatings, etc., can solve the problems of easily damaged coating integrity, anti-corrosion coating nanoparticles and large amounts of corrosion inhibitors, etc. Effective protection, corrosion inhibition, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

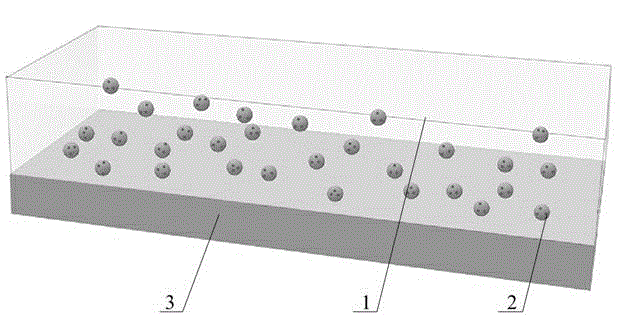

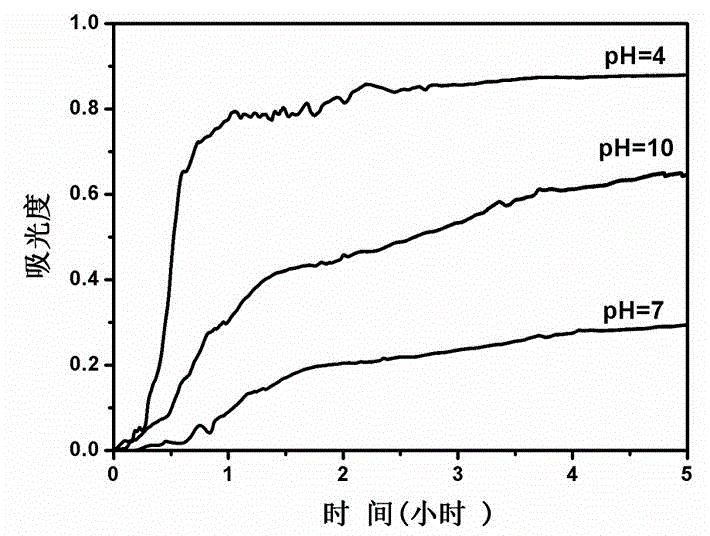

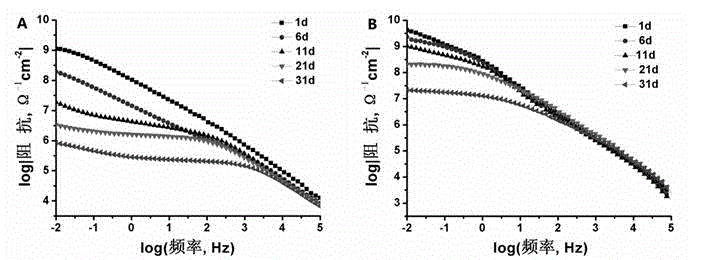

Image

Examples

Embodiment 1

[0029] Step 1, preparing silica mesoporous microspheres (MSNs).

[0030] 1. Mix 1.0g of cetyltrimethylammonium bromide (CTAB), 3.5mL of 2mol / L sodium hydroxide (NaOH) solution with 480mL of water, and heat to 80 under mechanical stirring (500 rpm). °C, condense and reflux for 1 hour to fully activate cetyltrimethylammonium bromide;

[0031] 2. Add 5.0mL tetraethyl orthosilicate (TEOS) dropwise to the mixture in step 1, and under vigorous stirring, a white solid will form within 10 minutes. After reacting at 80°C for 2 hours, filter while hot, and dissolve with water and methanol The product was fully washed and dried under vacuum at 70°C to obtain a solid;

[0032] 3. Weigh 1.0g dry solid, ultrasonically disperse it in a mixed solution of 150mL methanol and 10mL concentrated hydrochloric acid, reflux at 65°C for 6h, centrifuge, wash thoroughly with water and methanol, and dry in vacuum at 70°C to obtain silica mesoporous microspheres (MSNs).

[0033] Step 2, adsorbing L-his...

Embodiment 2

[0041] Step 1, preparing silica mesoporous microspheres (MSNs).

[0042] 1. Mix 1.0g of cetyltrimethylammonium bromide (CTAB), 3.5mL of 2mol / L sodium hydroxide (NaOH) solution with 480mL of water, and heat to 90 under mechanical stirring (500 rpm). ℃, reflux for 1.5 hours to fully activate cetyltrimethylammonium bromide;

[0043] 2. Add 5.0mL tetraethyl orthosilicate (TEOS) dropwise to the mixture in step 1, and under vigorous stirring, a white solid will form within 10 minutes. After reacting at 90°C for 2.5 hours, filter while hot, and dissolve with water and methanol The product was fully washed, and dried under vacuum at 70°C to obtain a solid;

[0044] 3. Weigh 1.0g dry solid, ultrasonically disperse it in a mixed solution of 100mL methanol and 10mL concentrated hydrochloric acid, reflux at 70°C for 4h, centrifuge, wash thoroughly with water and methanol, and dry in vacuum at 70°C to obtain silica mesoporous microspheres (MSNs).

[0045] Step 2, adsorbing L-histidine i...

Embodiment 3

[0053] Step 1, preparing silica mesoporous microspheres (MSNs).

[0054] 1. Mix 1.0g cetyltrimethylammonium bromide (CTAB), 3.5mL 2mol / L sodium hydroxide (NaOH) solution with 480mL water, heat to 84 ℃, reflux for 1.5 hours to fully activate cetyltrimethylammonium bromide;

[0055] 2. Add 5.0mL tetraethyl orthosilicate (TEOS) dropwise to the mixture in step 1. Under vigorous stirring, a white solid will form within 10 minutes. After reacting at 89°C for 2.5 hours, filter it while it is hot, and dissolve it with water and methanol. The product was fully washed and dried under vacuum at 70°C to obtain a solid;

[0056] 3. Weigh 1.0g dry solid, ultrasonically disperse it in a mixed solution of 100mL methanol and 10mL concentrated hydrochloric acid, reflux at 70°C for 4h, centrifuge, wash thoroughly with water and methanol, and dry in vacuum at 68°C to obtain silica mesoporous microspheres (MSNs).

[0057] Step 2, adsorbing L-histidine in the silica mesoporous microspheres as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com