A kind of biochemical fuel and preparation method thereof

A biochemical and fuel technology, applied in fuel, petroleum industry, liquid carbon-containing fuel, etc., can solve problems such as waste of resources, achieve clean tail gas, excellent combustion effect, high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

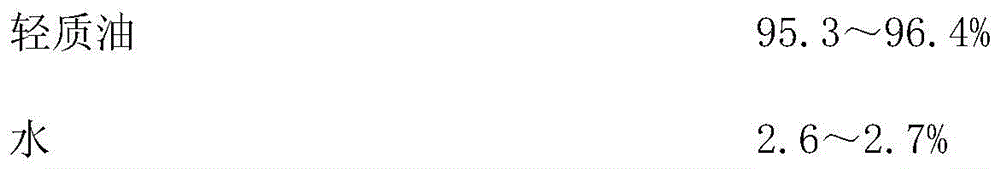

[0031] Taking the production of 1 ton of biochemical fuel as an example, the biochemical fuel of this embodiment is made up of raw materials of the following quality:

[0032]

[0033]

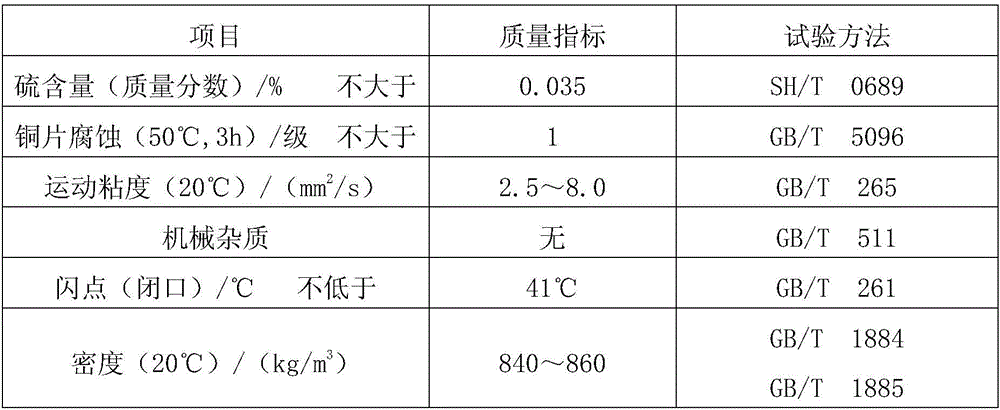

[0034] Described light oil density is 0.85g / cm 3 , 20℃ kinematic viscosity is 4.638mm 2 / s, the closed flash point is 42°C, no mechanical impurities, moisture < traces;

[0035] Described potassium hydroxide, sodium hydroxide, ethyl acetate, dehydrated alcohol are analytical reagents.

[0036] The preparation method of the biochemical fuel in this embodiment consists of the following steps:

[0037] (1) Accurately weigh 0.25 kg of potassium hydroxide and 0.25 kg of sodium hydroxide in proportion, dissolve potassium hydroxide and sodium hydroxide in 1 kg of water, stir to dissolve the solute completely, add 3 kg of ethyl acetate and anhydrous 5.5kg of ethanol, stirred for 4 minutes, the materials were fully mixed evenly, and left for 4 hours to obtain final product;

[0038] (2) Accur...

Embodiment 2

[0041] Taking the production of 1 ton of biochemical fuel as an example, the biochemical fuel of this embodiment is made up of raw materials of the following quality:

[0042]

[0043]

[0044] Described light oil density is 0.85g / cm 3 , 20℃ kinematic viscosity is 4.638mm 2 / s, the closed flash point is 42°C, no mechanical impurities, moisture < traces;

[0045] Described potassium hydroxide, sodium hydroxide, ethyl acetate, dehydrated alcohol are analytical reagents.

[0046] The preparation method of the biochemical fuel in this embodiment consists of the following steps:

[0047](1) Accurately weigh 0.5 kg of potassium hydroxide and 0.5 kg of sodium hydroxide in proportion, dissolve potassium hydroxide and sodium hydroxide in 2 kg of water, stir to dissolve the solute completely, add 6 kg of ethyl acetate and anhydrous 11kg of ethanol, stirred for 5 minutes, the materials were fully mixed evenly, and left for 3 hours to obtain final product;

[0048] (2) Accuratel...

Embodiment 3

[0051] Taking the production of 1 ton of biochemical fuel as an example, the biochemical fuel of this embodiment is made up of raw materials of the following quality:

[0052]

[0053] Described light oil density is 0.85g / cm 3 , 20℃ kinematic viscosity is 4.638mm 2 / s, the closed flash point is 42°C, no mechanical impurities, moisture < traces;

[0054] Described potassium hydroxide, sodium hydroxide, ethyl acetate, dehydrated alcohol are analytical reagents.

[0055] The preparation method of the biochemical fuel in this embodiment consists of the following steps:

[0056] (1) Accurately take by weighing potassium hydroxide 0.35kg and sodium hydroxide 0.35kg in proportion, get 1.4kg water dissolving potassium hydroxide and sodium hydroxide, after stirring to make solute dissolve completely, add ethyl acetate 4.2kg and 7.7kg of absolute ethanol, stirred for 3 minutes, the materials were fully mixed evenly, and left for 2 hours to obtain final product;

[0057] (2) Accur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com