Preparing method for composite type gentle and moistening soap base

A compound and mild technology, applied in the direction of chemical instruments and methods, detergent compositions, alkali soap/ammonium soap composition, etc., can solve the problems of strong cleaning ability, high energy consumption of machines, and large irritation, and achieve improved The effect of high utilization rate, high reuse rate and simple production equipment

Inactive Publication Date: 2015-09-23

深圳卓野日用品有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Traditional soap (representing comfortable soap, Liby soap, etc.) mainly produces raw materials: soap base (the soap making raw materials mentioned below refer to soap base) can only rely on large-scale machinery and equipment to pass vegetable oil or animal oil, recycled oil, etc. Neutralize and saponify with sodium hydroxide to obtain soap base, water and glycerin. After vacuum drying the soap base, extrude bars into soap particles, and by-product glycerin and some waste water. This method is relatively traditional, and there is a certain amount of waste water. Possess a certain area of venue and purchase expensive equipment and technical personnel

[0003] If the soap base is misoperated in the production process, all the batches will be scrapped and cannot be put back into the cauldron for reproduction, resulting in a waste of resources

[0004] The soap base removes the moisturizing glycerin component in the final stage of production, and the rest is mostly fat dry sodium soap. It is not the best if used in the production of cosmetic cleansing soap and other mid-to-high-end cleansing products, which are highly irritating and alkaline High sex (PH value), strong cleaning ability and easy to make people feel uncomfortable

[0005] The traditional soap made of this soap base also needs corresponding large and medium-sized equipment and a certain area of use site. The machine consumes a lot of energy, which conflicts with energy saving and emission reduction. Extrusion→stamping and printing→finished products are not suitable for small and micro enterprises and e-commerce enterprises that are currently encouraged by the government.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0043] 8% fatty acid, 20% polyalcohol, 25% sucrose, 22% purified water, and 18% surfactant were saponified with 7% sodium hydroxide.

Embodiment 2

[0045] 30% fatty acid, 20% polyhydric alcohol, 22% sucrose, 3% purified water, and 18% surfactant were saponified with 7% sodium hydroxide.

Embodiment 3

[0047]20% fatty acid, 30% polyhydric alcohol, 20% sucrose, 15% purified water, 9.95% surfactant, 0.05% titanium dioxide are saponified with 5% sodium hydroxide.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

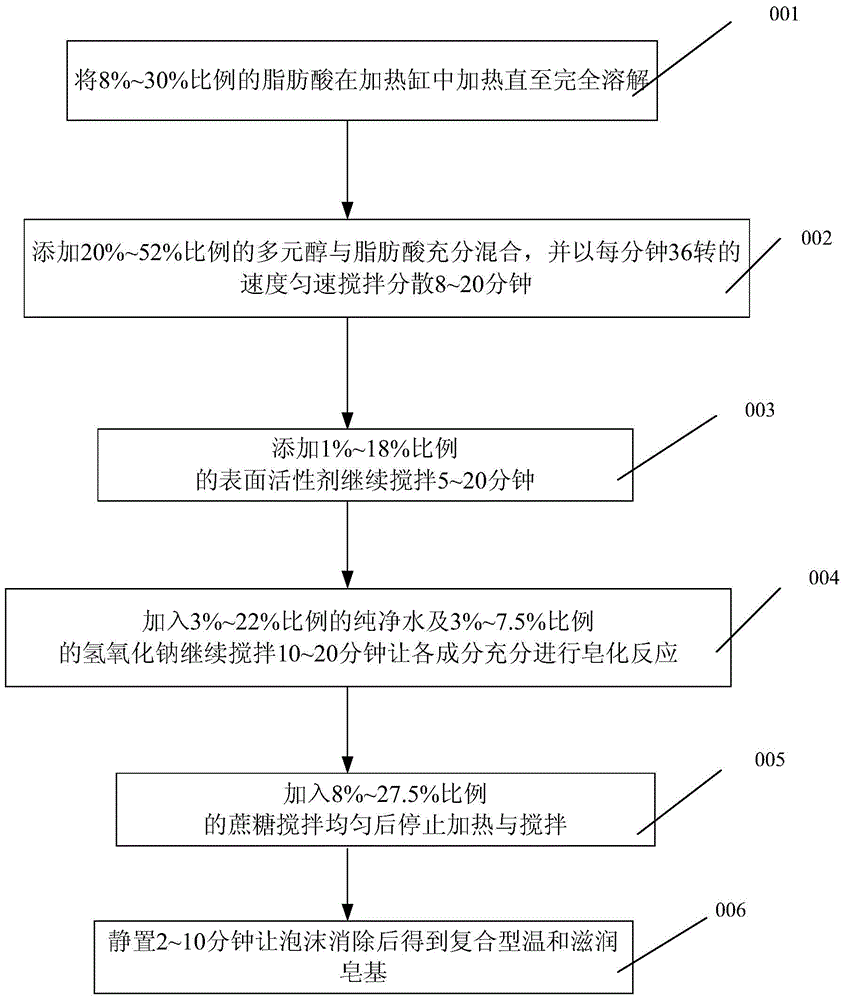

The invention provides a preparing method for a composite type gentle and moistening soap base. The preparing method for the composite type gentle and moistening soap base comprises the steps that saponification reaction is carried out on fatty acid with the proportion ranging from 8% to 30%, polyhydric alcohol with the proportion ranging from 20% to 52%, cane sugar with the proportion ranging from 8% to 27.5%, purified water with the proportion ranging from 3% to 22%, a surface active agent with the proportion ranging from 1% to 18% through sodium hydroxide with the proportion ranging from 3% to 7.5%. The method has the advantages that repeated dissolution can be achieved, the utilization rate can be increased, polyhydric alcohol moisture components are added in the production process, the skin irritant of the soap is lowered, and the moisture degree on the skin is improved. Wastes are not produced in the producing process, big-scaled devices and middle-scaled devices are not needed, a producing device is simple, and minimum conditions and factory mass production conditions exist. In addition, the repeated utilization rate of the soap base is high, redissolution can be carried out on the soap with the mass production due to the inaccurate statistical quantity during producing, the soap with other types can be manufactured, and the resource wastes cannot be caused.

Description

technical field [0001] The invention relates to the technical field of soap, in particular to a preparation method of a composite mild and moisturizing soap base. Background technique [0002] Traditional soap (representing comfortable soap, Liby soap, etc.) mainly produces raw materials: soap base (the soap making raw materials mentioned below refer to soap base) can only rely on large-scale machinery and equipment to pass vegetable oil or animal oil, recycled oil, etc. Neutralize and saponify with sodium hydroxide to obtain soap base, water and glycerin. After vacuum drying the soap base, extrude bars into soap particles, and by-product glycerin and some waste water. This method is relatively traditional, and there is a certain amount of waste water. Have a certain area of venue and purchase expensive equipment and technical personnel. [0003] If the soap base is misoperated in the production process, all the batches will be scrapped, and it cannot be put back into the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11D9/02C11D9/60C11D9/26

Inventor 罗晓安

Owner 深圳卓野日用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com