Anthocyanin sustained-release microcapsule, preparation method thereof and skin care product

A technology of anthocyanins and skin care products, applied in the field of skin care products, can solve problems such as limiting the application of anthocyanins and losing biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

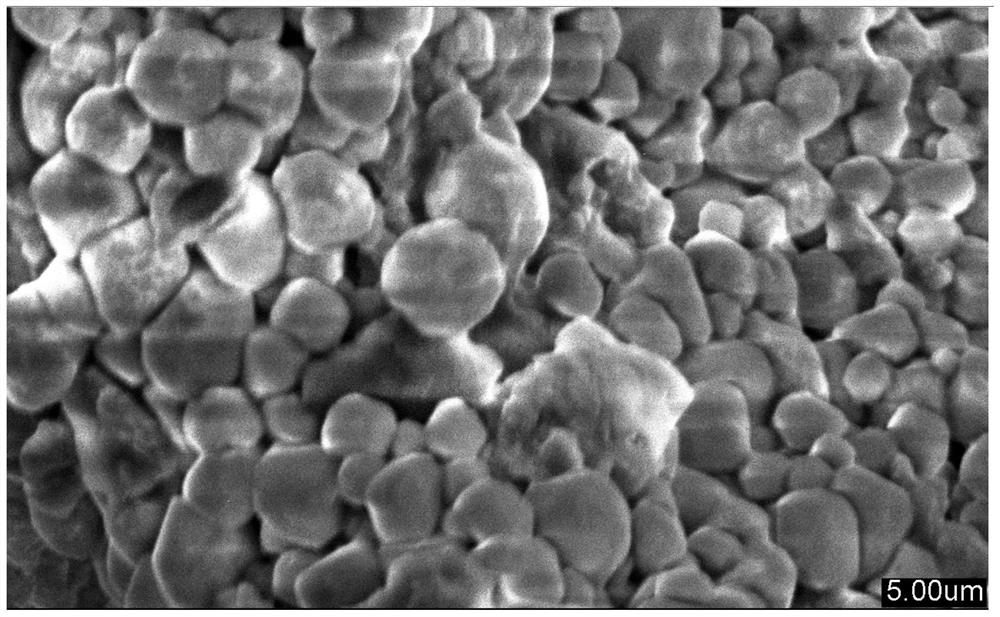

Image

Examples

preparation example Construction

[0057] One embodiment of the present invention provides a preparation method of anthocyanin sustained-release microcapsules, comprising the following steps S10-20.

[0058] Step S10, providing capsule material and anthocyanin, the capsule material is selected from at least one of sericin peptide and silk peptide, the molecular weight of the sericin peptide is not greater than 3000 Daltons, and the molecular weight of the silk fibroin peptide is not greater than 3000 Daltons.

[0059] In some of the embodiments, the preparation step of sericin peptide includes the following step S11.

[0060] Step S11, enzymatically hydrolyzing sericin with neutral protease to obtain sericin peptides with a molecular weight not greater than 3000 Daltons.

[0061] In some of the embodiments, the preparation step of the silk fibroin peptide includes the following step S12.

[0062] Step S12, subjecting silk fibroin to alkaline hydrolysis and acid protease enzymolysis in sequence to obtain silk ...

Embodiment 1

[0121] (1) Separation of glue silk: remove impurities from the silk and cut it to 1cm 2 Around small pieces, at 0.5wt% Na 2 CO 3 In the aqueous solution, the ratio of solid to liquid is 1:10, after boiling for 0.5h, filter, and the filter residue is boiled again with an aqueous alkali solution, and this is repeated 3 times, and the obtained insoluble matter is washed with distilled water to obtain silk fibroin.

[0122] (2) Preparation of silk fibroin peptide: mix the silk fibroin obtained in step (1) with 5wt% NaOH solution, the ratio of solid to liquid is 1:100, hydrolyze at 60° C. for 2 hours, drain after hydrolysis to obtain a hydrolyzate. Then the hydrolyzate was mixed with 7000u / g acid protease, the ratio of solid to liquid was 1:100, the pH value of the system after mixing was 4, and hydrolyzed at 50°C for 4 hours to obtain the enzymatic hydrolyzate. Finally, a Sephadex G-25 Sephadex column (2.0×60 cm) was used to purify the silk fibroin hydrolyzate, and a 0.02 mol / L,...

Embodiment 2

[0127] (1) Separation of glue silk: remove impurities from the silk and cut it to 1cm 2 Around small pieces, at 0.5wt% Na 2 CO 3 In the aqueous solution, the ratio of solid to liquid is 1:30, after boiling for 0.5h, filter, the filter residue is boiled again with alkaline aqueous solution, and the combined filtrate is sericin.

[0128] (2) Preparation of sericin peptide: use the sericin solution obtained in step (1) as raw material, adjust the pH to 7, add 2wt% neutral protease, the ratio of solid to liquid is 1:50, and enzymatically hydrolyze at 55°C for 2h , using DA201-C macroporous adsorption resin to carry out chromatographic purification of the enzymatic hydrolyzate, the specific steps are: pass the sericin enzymatic hydrolyzate with a concentration of 10mg / mL through the chromatographic column at 0.5BV / h, and then wash with water, Gradient elution was carried out with 20%, 30% and 50% ethanol aqueous solution. A sericin peptide with an average molecular weight of 102...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com