Q550D high-strength steel with ultra-low carbon equivalent and production method thereof

A production method and ultra-low carbon technology, applied to ultra-low carbon equivalent Q550D high-strength steel and its production field, can solve the problems of unstable weldability, high and low strength and low plasticity of hot-rolled high-strength steel, and low impact power value, etc. The effect of low cost and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

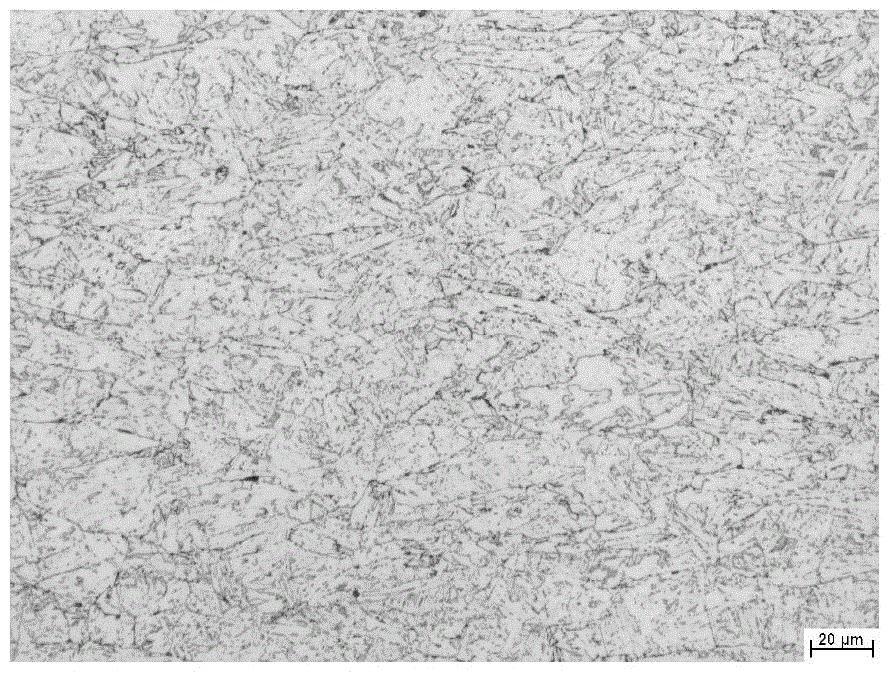

Image

Examples

Embodiment 1

[0024] A kind of Q550D high-strength steel with ultra-low carbon equivalent provided in this embodiment is produced by a reversible four-high rolling mill with a thickness of 30 mm as the rough rolling mill with a rolling force of 5,000 tons and a finishing mill with a rolling force of 4,000 tons. The standard Q550D high-strength steel is taken as an example. The specific element composition refers to Table 1, and the balance is Fe and unavoidable impurities.

[0025] The present invention also relates to a production method of the 30mm ultra-low carbon equivalent Q550D high-strength steel, the method comprising molten iron desulfurization pretreatment→converter smelting→RH refining→(LF refining)→continuous casting→slab stacking and slow cooling→slab inspection → Slab identification → Slab acceptance → Slab heating → Descaling → Rolling → Cooling → (Flaw detection) → Cutting, sampling → Printing marking → Inspection → Storage and other steps. details as follows:

[0026] Tabl...

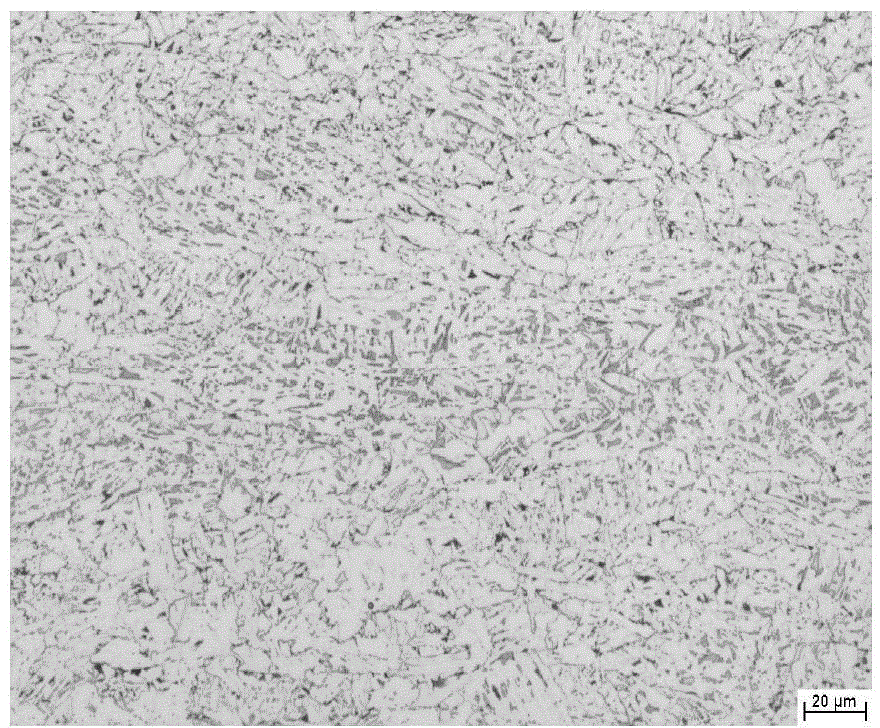

Embodiment 2

[0040] An ultra-low carbon equivalent Q550D high-strength steel provided in this embodiment is also taken as an example of a Q550D high-strength steel with a thickness specification of 30mm. The difference is the mass percentage of various elements, as shown in the following table:

[0041] Table 1-1 The actual weight percentage of the chemical composition of Q550D high-strength steel with a thickness of 30 mm

[0042]

[0043] Considering high strength and high impact performance requirements at -20°C, the medium-thickness steel plate enters the cooling device from 790-810°C and is cooled to 450-490°C in a short period of time. In the composition design, a small amount of low carbon is used to improve hardenability The Cr and B elements can improve the cooling rate and design ideas to meet the production requirements of high-grade equipment.

[0044] Table 2-1 Heating process

[0045]

[0046] Due to the high strength of the experimental steel, the 30mm thin-gauge stee...

Embodiment 3

[0053] An ultra-low carbon equivalent Q550D high-strength steel provided in this embodiment is also taken as an example of a Q550D high-strength steel with a thickness specification of 30mm. The difference is the mass percentage of various elements, as shown in the following table:

[0054] Table 1-2 The actual weight percentage of the chemical composition of Q550D high-strength steel with a thickness of 30 mm

[0055]

[0056] Considering high strength and high impact performance requirements at -20°C, the medium-thickness steel plate enters the cooling device from 790-810°C and is cooled to 450-490°C in a short period of time. In the composition design, a small amount of low carbon is used to improve hardenability The Cr and B elements can improve the cooling rate and design ideas to meet the production requirements of high-grade equipment.

[0057] Table 2-2 Heating process

[0058]

[0059] Due to the high strength of the experimental steel, the 30mm thin-gauge stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com