Downhole string lifting device

A downhole pipe string and short pipe technology, which is applied in the field of downhole pipe string lifting devices, can solve the problems of heavy weight, high working pressure, and high energy consumption, and achieve the effects of high degree of automation, low working air pressure, and large working stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

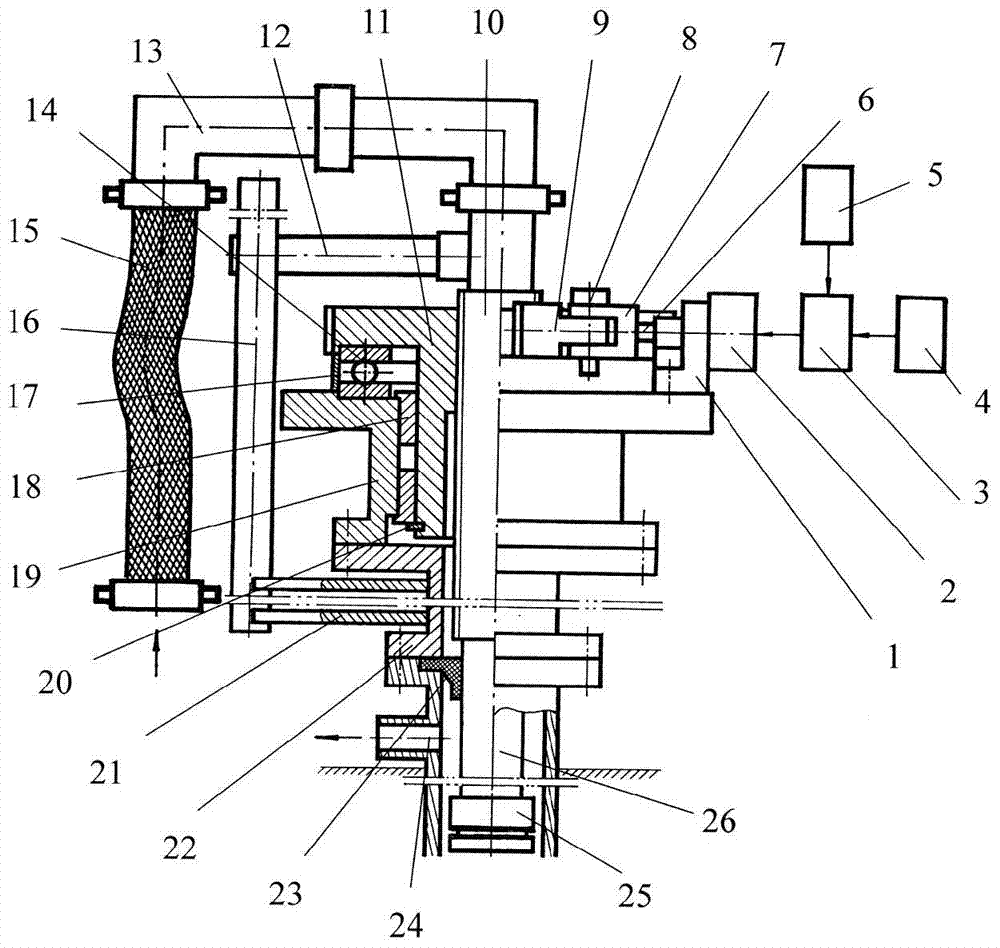

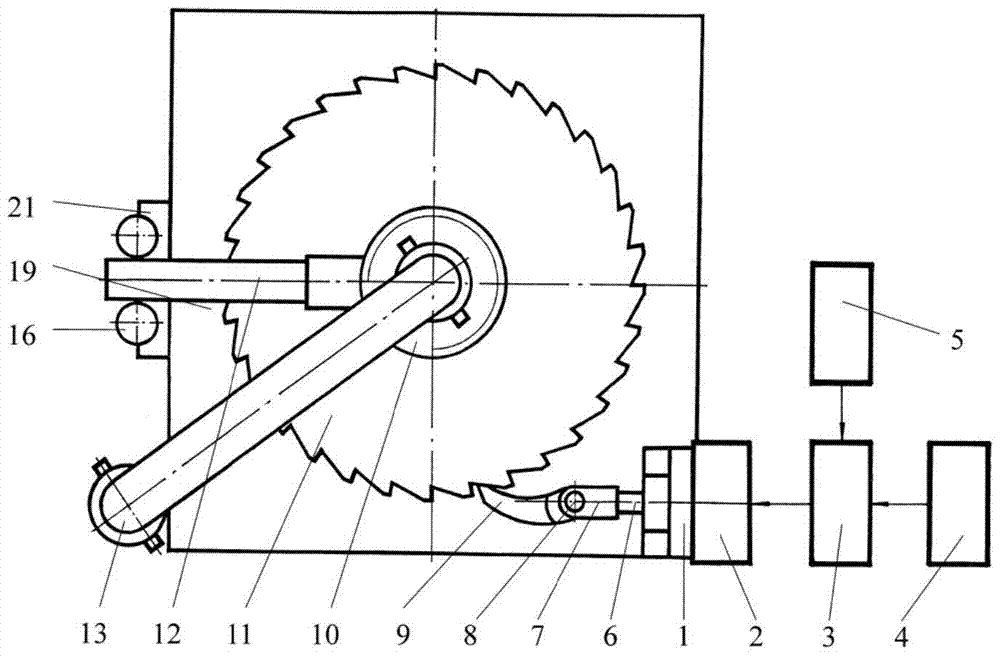

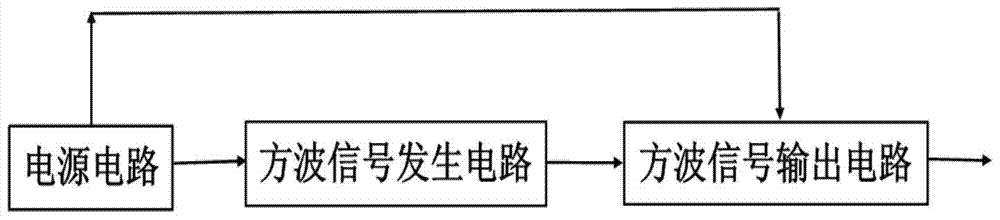

[0063] Example 1: One executive cylinder working mode

[0064] When using the downhole pipe string lifting device provided by the embodiment of the present invention to carry out oil field abrasive jet casing segment milling operations: the bottom of the downhole pipe string 26 is connected to the injector 25, the solenoid valve 3 adopts a two-position three-way solenoid valve, and the solenoid valve 3 It is connected to the output terminals A+ and A- of the controller 5, because the output terminals B+ and B- are not connected to the solenoid valve, so move the transfer switch K2 to connect pin 1 and pin 4, so that the output terminals B+ and B of the controller 5 - There is no signal output, and the execution cylinder 2 adopts a film cylinder. When the controller 5 outputs a square wave signal, the LED 2 emits green light, the solenoid valve 3 acts, the air pump 4 is connected to the execution cylinder 2, and the execution cylinder 2 pushes the ratchet 11 to rotate a ratchet...

Embodiment 2

[0065] Example 2: Synchronous working mode of two execution cylinders

[0066] When using a downhole pipe string lifting device provided by the embodiment of the present invention to carry out oil field abrasive jet casing segment milling operations: the bottom of the downhole pipe string 26 is connected to the injector 25, one air pump 4 is used, and two electromagnetic valves 3 are used. Three-way solenoid valves A and B, the executive cylinder uses 2 thin-film cylinders (executive cylinder 2-A and executive cylinder 2-B). The controller 5 has 2 output terminals A+, A- and B+, B-, move the changeover switch K2 of the controller 5 to connect its pin 1 and pin 2, at this time, the 2 output terminals A+ and A of the controller 5 - output synchronous square wave signal with B+, B-. The output terminals A+ and A- of the controller 5 are connected to the solenoid valve 3-A, and the solenoid valve 3-A is respectively connected to the air pump 4 and the execution cylinder 2-A. When...

Embodiment 3

[0068] Example 3: Asynchronous working mode of 2 execution cylinders

[0069] When using a downhole pipe string lifting device provided by the embodiment of the present invention to carry out oil field abrasive jet casing segment milling operations: the bottom of the downhole pipe string 26 is connected to the injector 25, one air pump 4 is used, and two electromagnetic valves 3 are used. Three-way solenoid valves A and B, the executive cylinder uses 2 thin-film cylinders (executive cylinder 2-A and executive cylinder 2-B). The controller 5 has 2 output terminals A+, A- and B+, B-, connect pin 1 and pin 3 of the transfer switch K2 of the controller 5, at this time, the 2 output terminals A+, A- and B+ of the controller 5 , B- output asynchronous square wave signal. The output terminals A+ and A- of the controller 5 are connected to the solenoid valve 3-A, and the solenoid valve 3-A is respectively connected to the air pump 4 and the execution cylinder 2-A. When the output ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com