Coal bed gas and methane gas coring and desorption measurement system and method

A measurement system and measurement method technology, applied in sampling devices, analysis materials, instruments, etc., can solve problems such as inaccurate loss gas estimation, low coalbed methane measurement value, test failure, etc., to achieve improved accuracy results, operability and Effects of improved safety performance and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

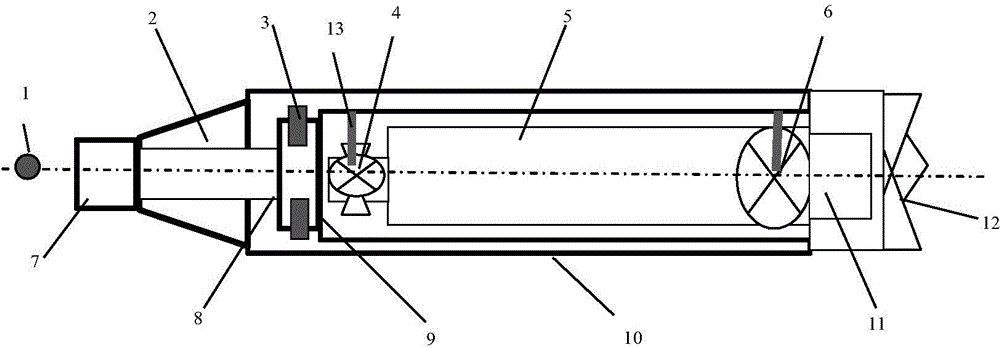

[0026] An example of the present invention is figure 1 shown. The integrated system for coring and desorption measurement is composed of three parts: coal sample coring and desorption system, closing and sealing system and supporting assembly system.

[0027] The coal sample coring and desorption system mainly consists of a desorption ball valve 4 , a desorption and coring integrated device 5 , a shearing ball valve 6 and a coal sample positioner 11 . This desorption and coring integrated device 5 is exactly a traditional coring tube and a desorption tank.

[0028] The closing and sealing system consists of a plugging ball 1, a hydraulic assembly 2, a pin 3, a hydraulic bearing 8 and a linkage shearing closing mechanism 9;

[0029] The matching assembly system consists of a drill pipe conversion joint 7, an outer jacket assembly 10 and a special core bit 12.

[0030] The desorption and core integrated device 5 of this embodiment adopts a new titanium steel material, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com