Nitrogen oxide sensor chip and preparation method thereof

A sensor chip, nitrogen oxide technology, applied in the direction of material electrochemical variables, can solve problems such as cost increase and signal interference, and achieve the effects of simplified structure, simplified preparation process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

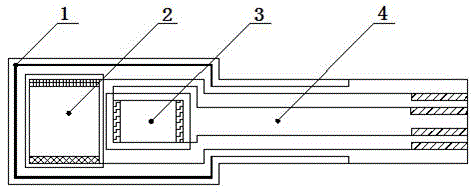

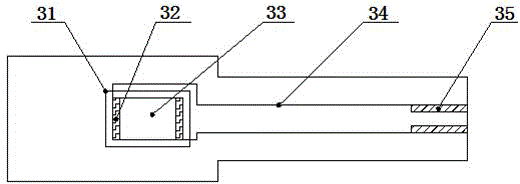

[0042] A nitrogen oxide sensor chip and a preparation method thereof. The nitrogen oxide sensor chip integrates a heating resistor 1 , a nitrogen oxide concentration battery 2 and an STF oxygen sensitive resistor 3 on the surface of an alumina substrate 4 . The projection positions of the heating resistor 1, the nitrogen oxide concentration cell 2 and the STF oxygen sensitive resistor 3 on the alumina substrate 4 are as follows: figure 1 As shown: the heating resistor 1 is symmetrically distributed near the periphery of the alumina substrate 4; the distance between the center of the nitrogen oxide concentration cell 2 and the left end of the alumina substrate 4 is 4 mm; the center of the STF oxygen-sensitive resistor 3 and the alumina substrate The distance between the left ends of the sheet 4 is 10 mm; the center of the nitrogen oxide concentration cell 2 and the center of the STF oxygen sensitive resistor 3 are located on the symmetry line of the alumina substrate 4 .

...

Embodiment 2

[0063] A nitrogen oxide sensor chip and a preparation method thereof. Except the following circumstances, all the other are with embodiment 1:

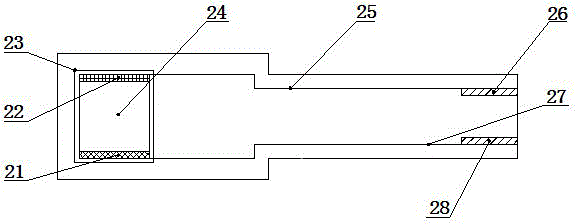

[0064] This example Figure 7 As shown, the heating resistors 1 are symmetrically distributed near the periphery of the alumina substrate 4 means that the heating resistors 1 are symmetrically distributed near the periphery of the back surface of the alumina substrate 4 .

[0065] This example Figure 6 and Figure 7 As shown, the planar shape of the alumina substrate 4 is a rectangle

[0066] Compared with the prior art, this specific embodiment has the following positive effects:

[0067] 1. The structure of the nitrogen oxide sensor chip in this specific embodiment is simple. At present, the exhaust gas nitrogen oxide sensor chip for vehicles is composed of six layers of zirconia substrates, consisting of three electrochemical oxygen pumps, two chambers, a reference air channel, a heating resistor, leads and eight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com