Piston-type first-order buoyancy magnetic liquid inertial sensor

An inertial sensor and magnetic liquid technology, applied in the direction of using inertial force for acceleration measurement, etc., can solve the problems of easy fragmentation of permanent magnets, difficult magnetic liquid flow, low viscous energy consumption efficiency, etc. Suspended, avoids the effect of difficult flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described with accompanying drawing as specific embodiment:

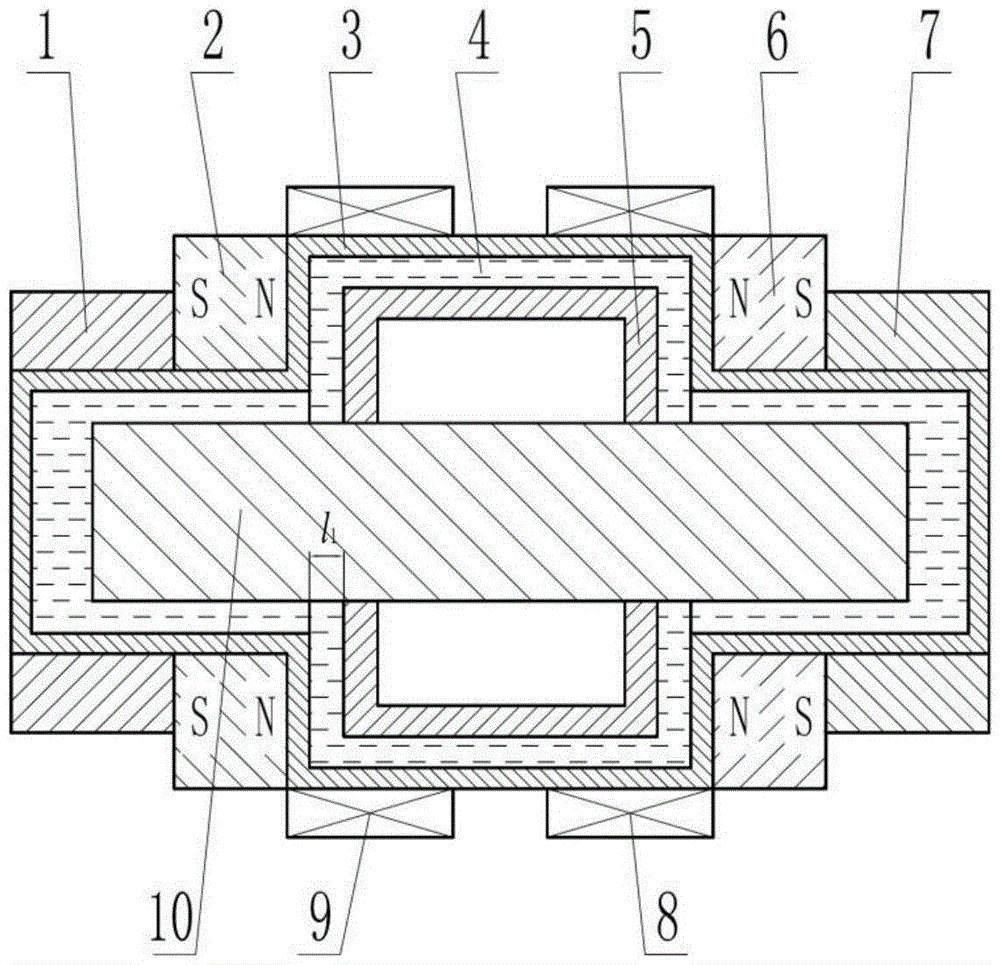

[0019] A piston-type first-order buoyancy magnetic liquid inertial sensor, such as figure 1 , the damping device includes: a first suspension permanent magnet 1, a first limit permanent magnet 2, a housing 3, a magnetic liquid 4, a limit shell 5, a second limit permanent magnet 6, a second suspension permanent magnet 7, The second induction coil 8 , the first induction coil 9 and the mass block 10 .

[0020] Connections between the parts making up the device:

[0021] The mass block 10 is inserted into the inner hole of the limiting shell 5 and fixedly connected so that the limiting shell 5 is located in the middle of the mass block 10, thereby forming a mass block assembly;

[0022] The housing 3 is filled with magnetic liquid 4, and the mass block assembly is loaded into the housing 3; after the housing 3 is sealed, the first limiting permanent magnet 2 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com