Thermal power generating unit coordination control method based on condensate throttling

A condensate water throttling and coordinated control technology, applied in the direction of electrical program control, program control, comprehensive factory control, etc., can solve the problems of limited available energy storage, difficulty in greatly increasing the variable load rate, etc., to achieve the improvement of variable load rate, the effect of improving schedulability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention proposes a thermal power unit coordinated control method based on condensed water throttling. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

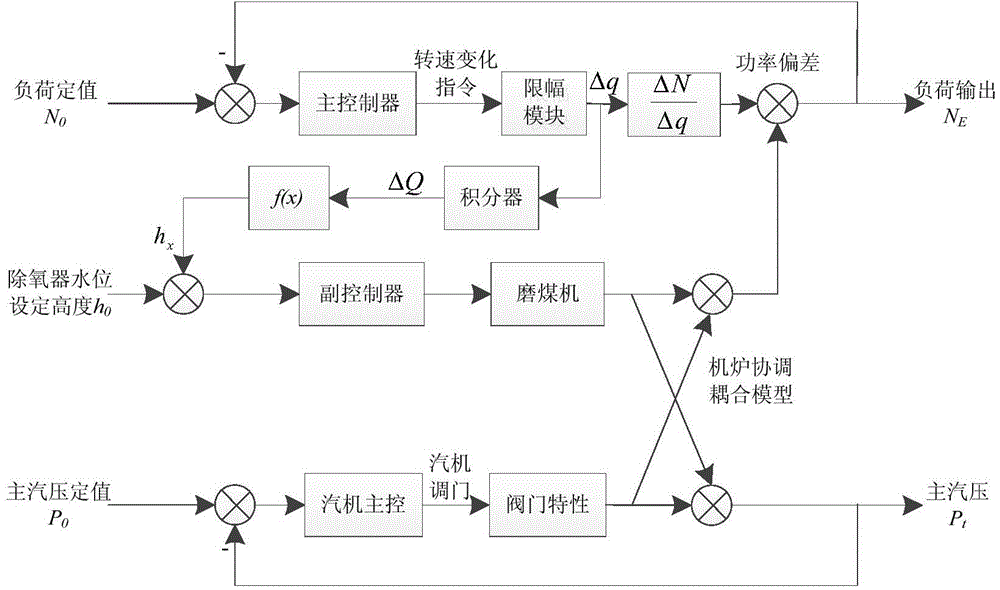

[0020] figure 1 The flow chart of the coordinated control of thermal power units based on condensate throttling is shown. The method of coordinated control of thermal power units based on condensate throttling specifically includes the following steps:

[0021] 1) The actual load and the given load form the load deviation of the unit and send it to the main controller;

[0022] 2) The main controller sends the speed change command of the condensate pump motor, and the speed change command changes the speed of the condensate pump motor after passing through the limiting module;

[0023] 3) The change of the motor speed of the condensate pump causes the change of the condensate flow, and the change of the condensate flow leads to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com