A kind of 125i radiation microsphere, its preparation method and microfluidic device

A technology of microspheres and spherical shells, applied in the field of radiation medicine, can solve the problems of low utilization rate of raw materials, expensive carrier materials, uneconomical and other problems, and achieve the effects of short time consumption, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

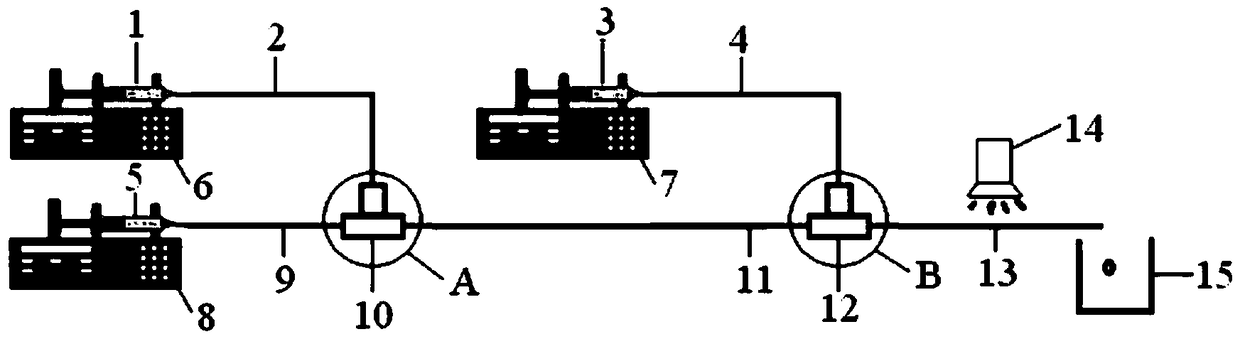

[0049] The present invention also provides a 125 The preparation method of 1 radiation microsphere comprises the following steps:

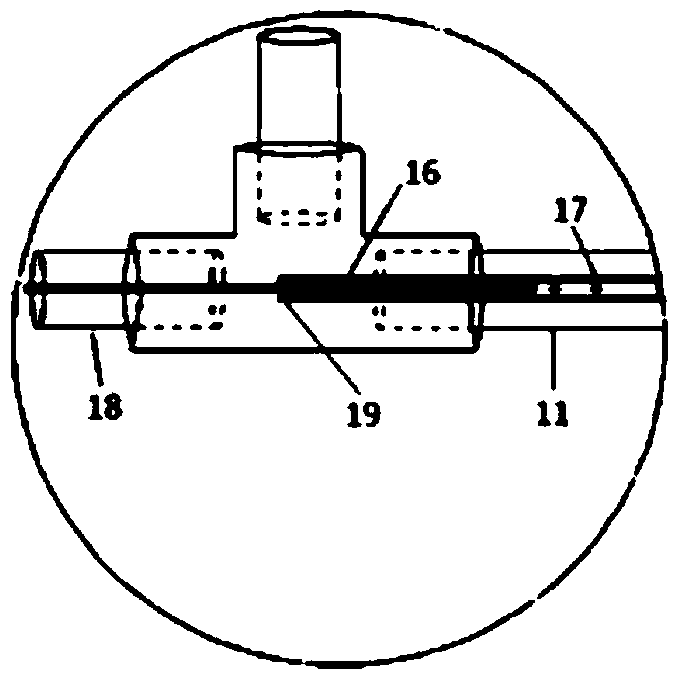

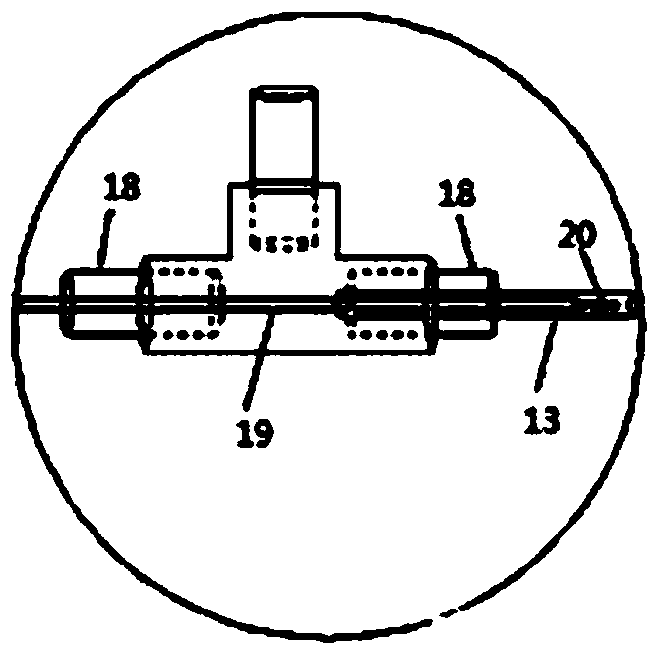

[0050] A) the capsule core phase solution and the capsule wall phase solution are merged to obtain the capsule wall phase solution wrapped around the capsule core phase liquid droplet; the capsule core phase solution includes 125 The solution of I, the capsule wall phase solution comprises tripropylene glycol diacrylate solution containing paclitaxel;

[0051] B) The capsule wall phase solution wrapped around the gel core phase droplet is merged with the continuous phase solution to obtain the capsule wall phase droplet wrapped around the gel core phase droplet, and the continuous phase solution includes simethicone, kerosene and one or more of liquid paraffin;

[0052] C) solidifying the capsule wall phase droplets wrapped around the glue core phase droplets to obtain 125 I Radiation Microspheres.

[0053] In the present invention, the gelati...

Embodiment 1

[0089] Take 2.76g deionized water and 0.24g containing 5mCi radioactive 125 Mix I nuclides with NaI, stir and dissolve with a glass rod, and make a colloidal nucleus phase solution.

[0090] Take 0.4g of paclitaxel (HCPK) and 9.6g of tripropylene glycol diacrylate (TPGDA) and mix them, stir them with magnetic force to dissolve, and make a cystic wall phase solution.

[0091] Take simethicone as the continuous phase solution.

[0092] Fill the above-mentioned core phase, capsule wall phase and continuous phase solutions into 1mL, 20mL and 20mL syringes, respectively, and place them on the corresponding syringe pumps, and connect to the microfluidic device. Set the flow rate of the glue core phase solution to 0.5 μL / min, the flow rate of the cyst wall phase solution to 3.5 μL / min, and the flow rate of the continuous phase solution to 120 μL / min. The size of the capillary of the colloid core phase is: inner diameter / outer diameter 100 μm / 167 μm, and the size of the capillary tu...

Embodiment 2

[0095] Take 1.82g deionized water and 0.18g containing 7mCi radioactive 125 Mix I nuclides with NaI, stir and dissolve with a glass rod, and make a colloidal nucleus phase solution.

[0096] Take 0.4g of paclitaxel (HCPK) and 9.6g of tripropylene glycol diacrylate (TPGDA) and mix them, stir them with magnetic force to dissolve, and make a cystic wall phase solution.

[0097] Take simethicone as the continuous phase solution.

[0098] Fill the above-mentioned core phase, capsule wall phase and continuous phase solutions into 1mL, 20mL and 20mL syringes, respectively, and place them on the corresponding syringe pumps, and connect to the microfluidic device. Set the flow rate of the glue core phase solution to 0.25 μL / min, the flow rate of the cyst wall phase solution to 3.75 μL / min, and the flow rate of the continuous phase solution to 120 μL / min. The size of the capillary of the colloid core phase is: inner diameter / outer diameter 100 μm / 167 μm, and the size of the capillary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com