Manufacture process of robot RV reducer spline eccentric shaft

An eccentric shaft and reducer technology, applied in the field of mechanical processing, can solve the problems of high processing positioning accuracy, slippage, spline eccentric shaft alignment error, etc., to improve processing accuracy and assembly accuracy, improve service life, and drive stable and reliable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

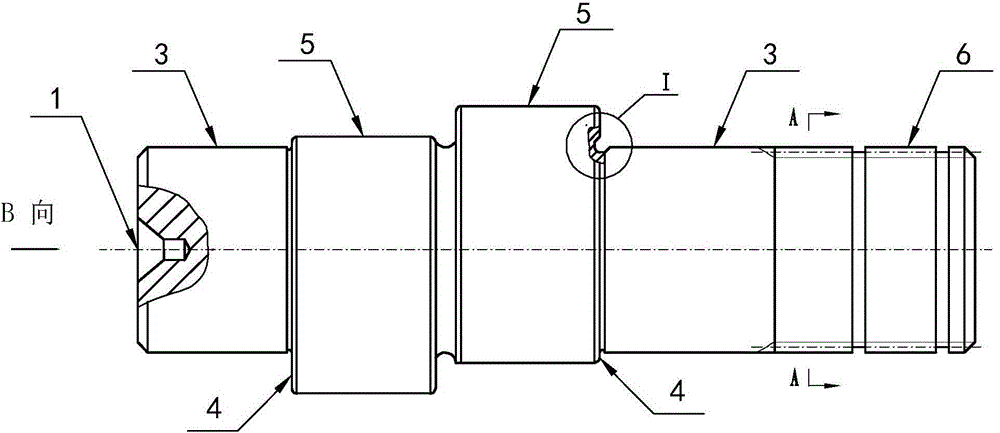

[0017] Referring to the accompanying drawings, a manufacturing process of a splined eccentric shaft of a robot RV reducer includes the following steps:

[0018] (A) Forging the spline eccentric shaft blank;

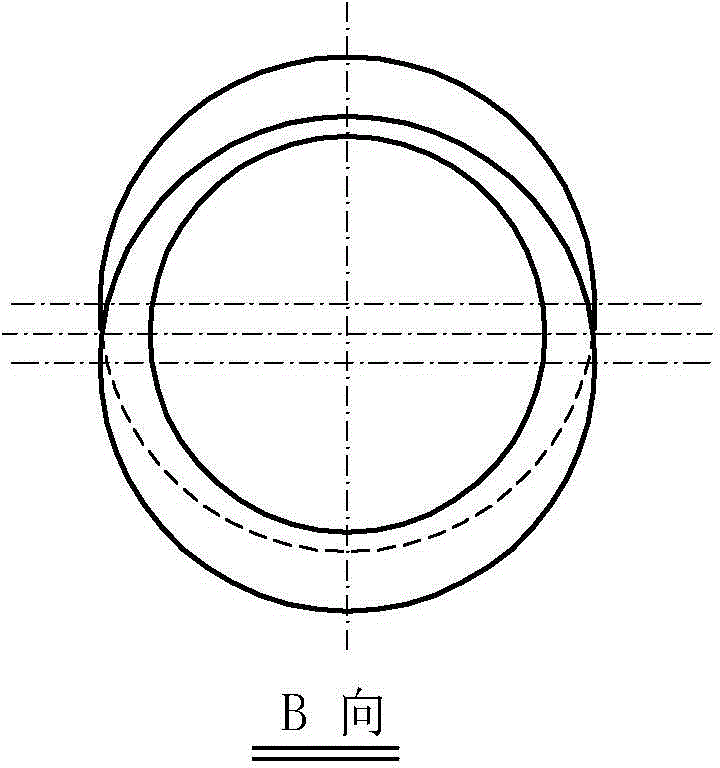

[0019] (B) Carrying out the rough turning of the spline eccentric shaft blank, drilling a center hole 1 on both ends of the spline eccentric shaft, milling a positioning groove 2 on the circumference of one end of the spline, and performing heat treatment;

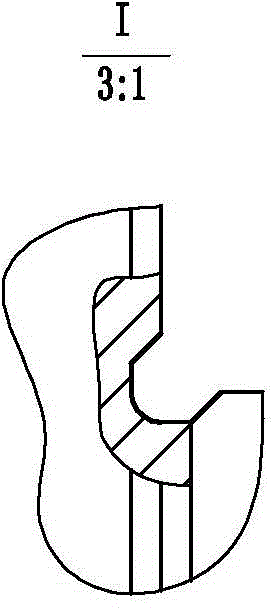

[0020] (C) Use the two top holes 1 as the positioning reference to finish machining two cams 5 close to the bearing position 3 of the tapered roller bearing to ensure the dimensional tolerance between the two cam processing end faces, and at the same time use the two top holes as the positioning reference to finish machining two The cam is close to the two end faces 4 of the bearing positions of the tapered roller bearings, ensuring the bearing position of each tapered roller bearing and the dimensional tolerance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com