Semi nitrosation-anaerobic ammonium oxidation combined type reactor as well as reaction process and system thereof

An anammox and reactor technology, which is applied in the field of reaction process and reaction system, can solve the problems of limiting ammonia nitrogen removal capacity, influence of reaction efficiency of anammox reaction zone, etc., and achieves the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

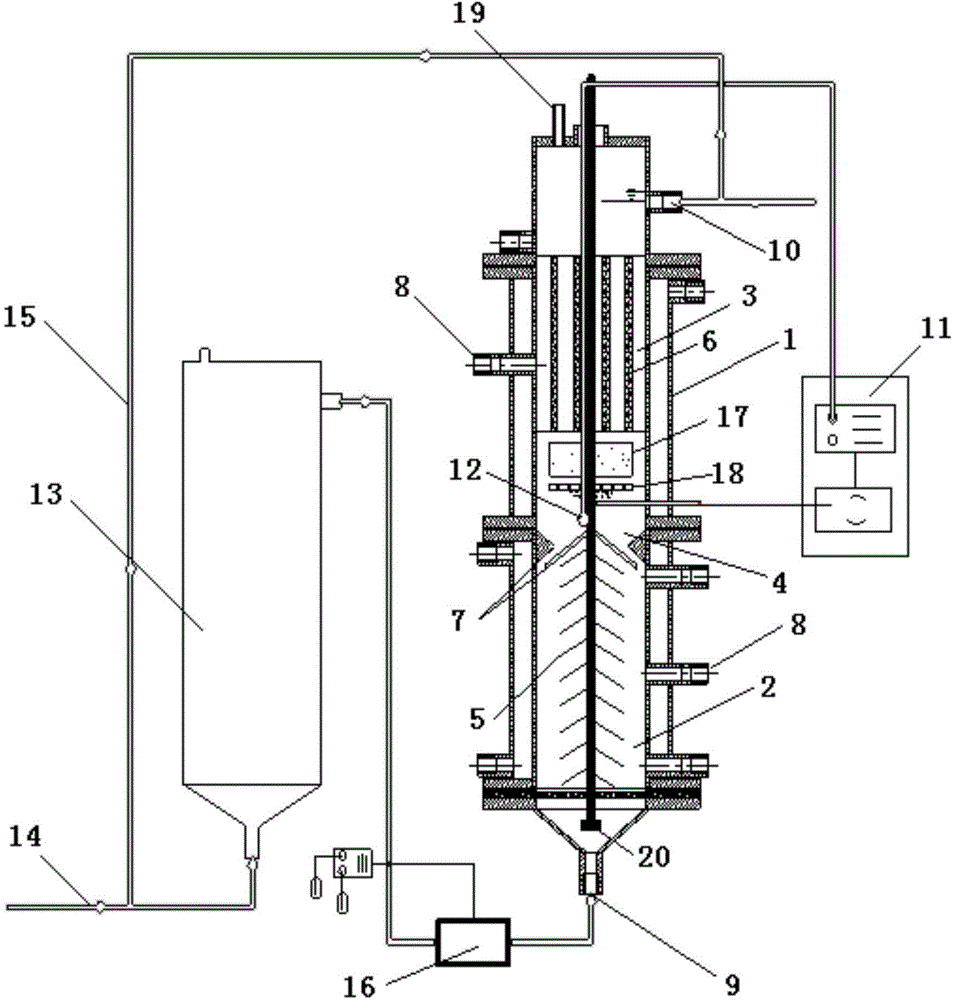

[0036] This embodiment provides a semi-nitrosation-ANAMMOX combined reactor, including:

[0037] Cylindrical reactor shell 1, the bottom of the reactor shell 1 is provided with a waste water inlet 9, and the top is provided with a drain port 10 and an exhaust port 19; A semi-nitrification zone 2, a transition zone 4, and anammox zone 3 are set up in sequence, wherein the ratio of the heights of the semi-nitrification zone 2, transition zone 4, and the anammox zone 3 is 1.3:1 :1.6.

[0038] An oxygen-containing gas aeration port 20 is arranged in the semi-nitrification area 2, and the oxygen-containing gas aeration port 20 is arranged close to the water inlet; a BF filler 5 is also provided in the semi-nitrification area 2; The BF filler 5 is a plurality of cylindrical fillers arranged parallel to the central axis of the semi-nitrification zone 2, and semi-nitroso bacteria are attached to the BF filler 5; the total cross-sectional area of the plurality of BF fillers 5 is the...

Embodiment 2

[0050] This embodiment provides a semi-nitrosation-ANAMMOX combined reactor, including:

[0051] Cylindrical reactor shell 1, the bottom of the reactor shell 1 is provided with a waste water inlet 9, and the top is provided with a drain port 10 and an exhaust port 19; A semi-nitrification zone 2, a transition zone 4, and anammox zone 3 are set up in sequence, wherein the height ratio of the semi-nitrification zone 2, transition zone 4, and the anammox zone 3 is 1.2:1 :1.5.

[0052] An oxygen-containing gas aeration port 20 is arranged in the semi-nitrification area 2, and the oxygen-containing gas aeration port 20 is arranged close to the water inlet; a BF filler 5 is also provided in the semi-nitrification area 2; The BF filler 5 is a plurality of cylindrical fillers arranged parallel to the central axis of the semi-nitrification zone 2, and semi-nitroso bacteria are attached to the BF filler 5; the total cross-sectional area of the plurality of BF fillers 5 is the same as...

Embodiment 3

[0064] This embodiment provides a semi-nitrosation-ANAMMOX combined reactor, including:

[0065] Cylindrical reactor shell 1, the bottom of the reactor shell 1 is provided with a waste water inlet 9, and the top is provided with a drain port 10 and an exhaust port 19; The semi-nitrification zone 2, the transition zone 4 and the anammox zone 3 are set up in sequence, wherein the height ratio of the semi-nitrification zone 2, the transition zone 4 and the anammox zone 3 is 1:1 : 1.3.

[0066] An oxygen-containing gas aeration port 20 is arranged in the semi-nitrification area 2, and the oxygen-containing gas aeration port 20 is arranged close to the water inlet; a BF filler 5 is also provided in the semi-nitrification area 2; The BF filler 5 is a curved surface filler that is helically wound along the central axis of the semi-nitrification zone 2, and semi-nitrosifying bacteria are attached to the BF filler 5; the diameter of the BF filler 5 is the same as that of the reactor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com