Reverse screw spike pile and construction method thereof

A screw and reverse technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve limited problems, and can only be applied in clay soil, silt, filling and other soil layers, and the workload of excavation and transportation is large. Insufficient adaptability of soil layers, etc., to achieve the effect of easy control of construction quality, easy control of construction process, and many types of applicable strata

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

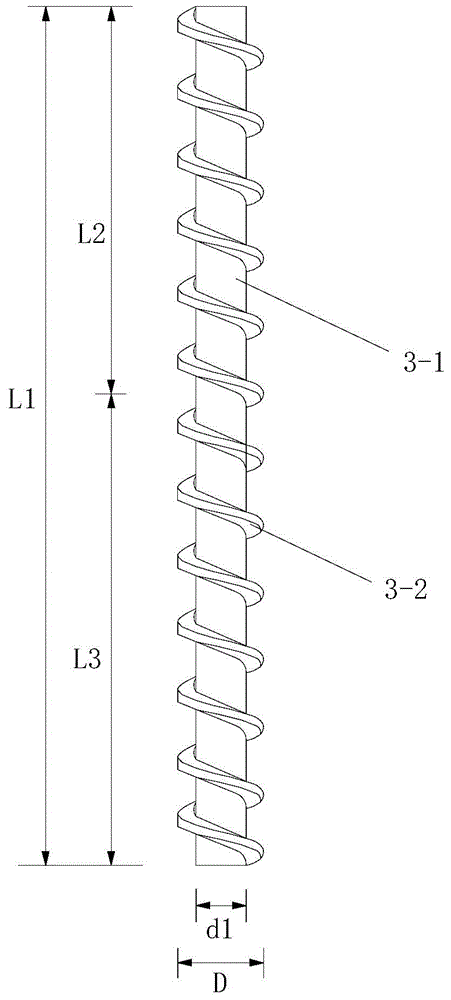

[0062] Such as figure 1 , figure 2 The shown reverse screw pile includes a pile body, and the pile body is a concrete pile body; the pile body is a fully threaded pile body or a partially threaded pile body.

[0063] Such as figure 1 As shown, the fully threaded pile body includes a first pile core 3-1 and a first external thread structure 3-2 arranged on the outer wall of the first pile core 3-1 from top to bottom; the first pile core 3-1 is cylindrical, and the first external thread structure 3-2 is poured integrally with the first pile core 3-1.

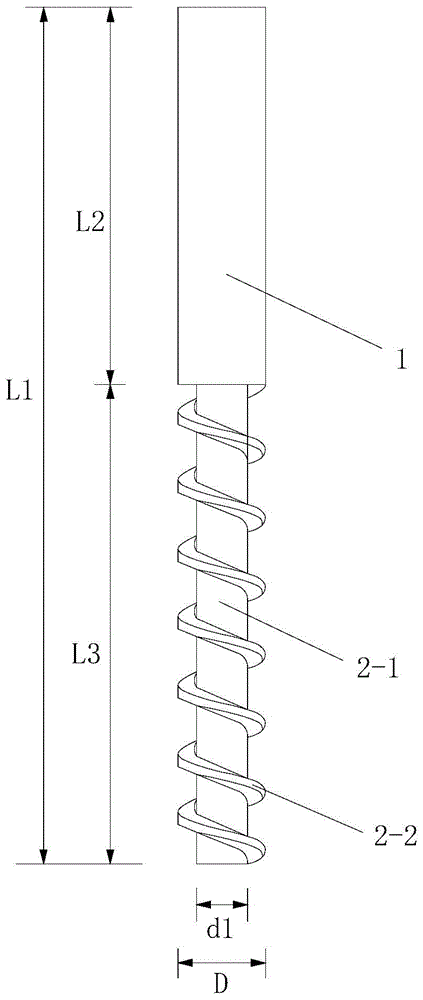

[0064] Such as figure 2 As shown, the part of the threaded pile body includes a lower pile body 1 and an upper pile body 2 directly above the lower pile body 1, the lower pile body 1 is a threaded section pile body, and the upper pile body 2 is a straight rod section Pile body, the pile body of the straight rod section is cylindrical and it is arranged coaxially with the pile body of the threaded section; the pile body of th...

Embodiment 2

[0097] In this embodiment, the reverse screw pile constructed is different from Embodiment 1 in that: the pile body is a reinforced concrete structure, and a reinforcement cage is arranged inside the pile body.

[0098] In this embodiment, the structure of the rest of the reverse screw pile constructed is the same as that of Embodiment 1.

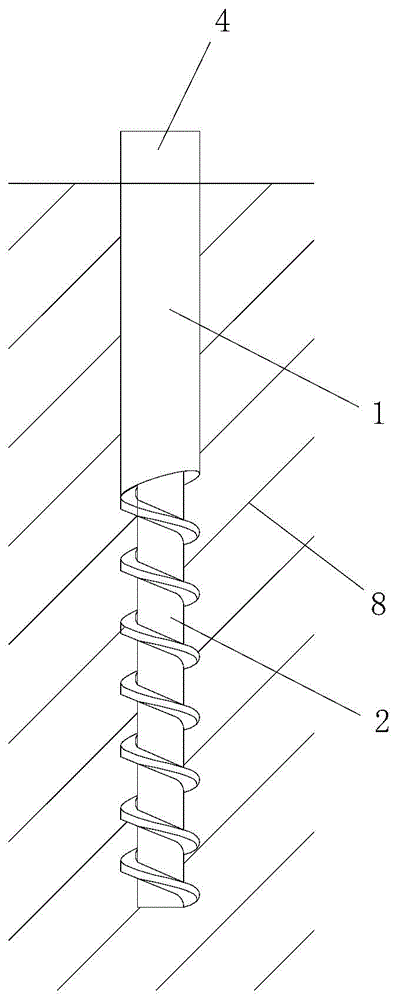

[0099] In this example, if Figure 10 As shown, when constructing reverse screw piles, the following steps are included:

[0100] Step 1, the drill pipe of the pile driver is in place: the drill pipe 5 of the screw pile driver is moved to the pile position where the reverse screw pile needs to be constructed; the pile body of the reverse screw pile to be constructed is provided with a reinforcement cage;

[0101] The screw pile driver includes a pile frame and a drilling device installed on the pile frame. The drilling device includes a drill rod 5 and an electric rotary drive mechanism that drives the drilling device to rotate continuousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com