Sheet type light source system of laser beam

A laser beam and sheet light source technology, applied in the direction of fluorescence/phosphorescence, optics, optical components, etc., can solve the problem of easy deviation of laser beam conduction, large spread of beam diameter, and optical coupling efficiency of single-mode fiber and laser beam device is less than 50 % and other issues, to achieve the effect of flexible and convenient sheet light layout, low-loss transmission guarantee, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

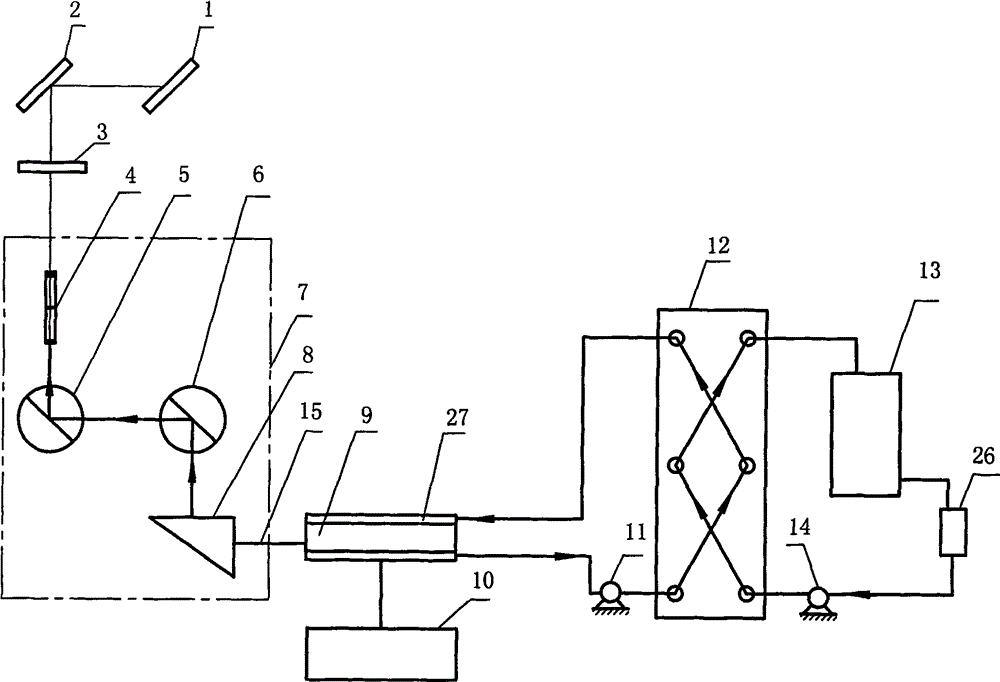

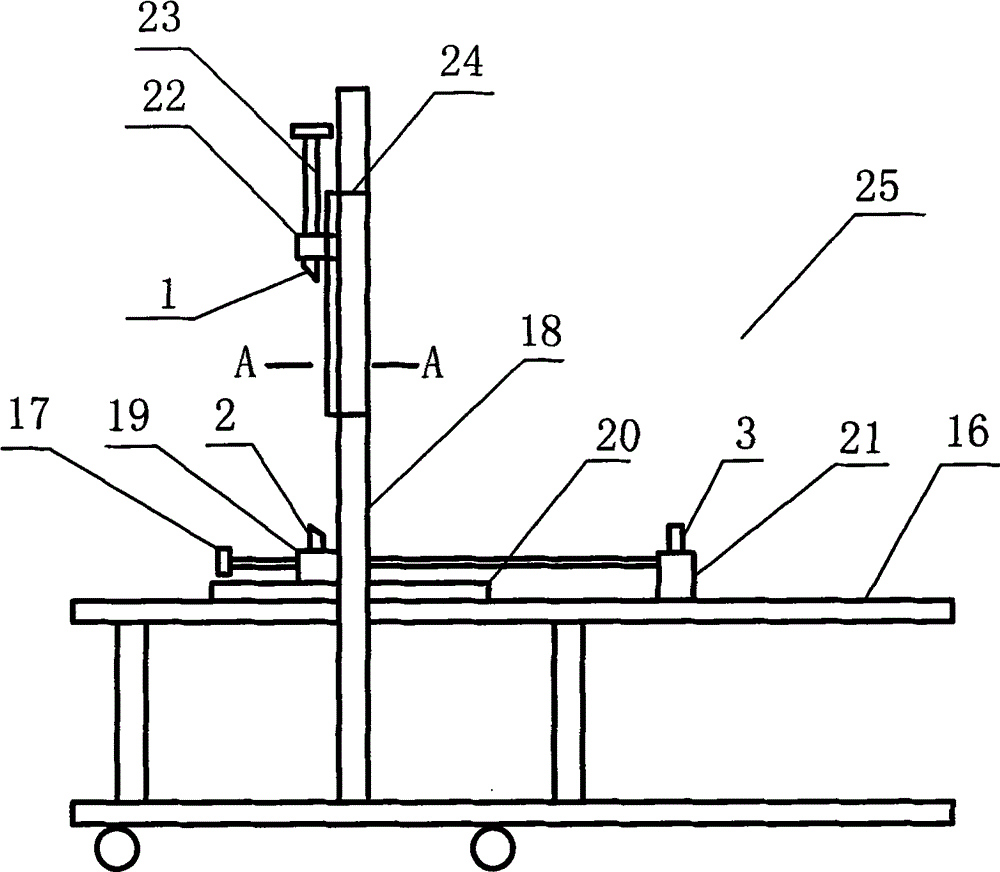

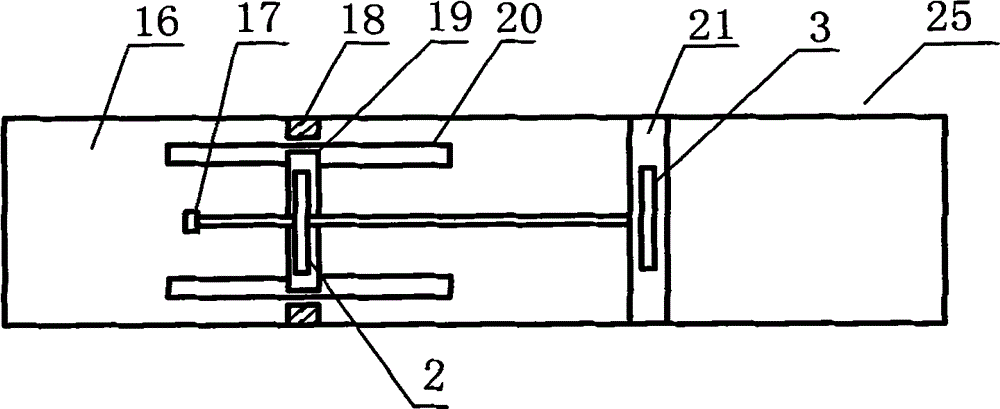

[0021] Such as figure 1 As shown, the laser beam sheet light source system of the present invention includes: a first reflector 1, a second reflector 2, a Fresnel lens 3, a grid fine-tuning device 7, an argon ion laser 9, a heat exchanger 12, and a cooling tower 13 , control host 10 and filter 26, one end of heat exchanger 12 and cooling tower 13 form an external circulation loop, a second pump 14 is housed in the external circulation loop of heat exchanger 12, and second pump 14 is contained in cooling tower 13 and heat exchanger 12. The other end of the heat exchanger 12 forms an inner circulation loop with the resonant cavity cooling chamber 27 of the argon ion laser 9, and a first pump 11 is installed in the inner circulation loop of the heat exchanger 12, and the first pump 11 is installed in the inner circulation loop of the argon ion laser. Between the resonant cavity cooling chamber 27 of 9 and the heat exchanger 12, the cooling water in the inner circulation loop is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com