Manufacturing method and structure of current limiting control diode

A technology of current limiting control and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of unsatisfactory manufacturing methods or structures, achieve safety and reliability, quickly limit current, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

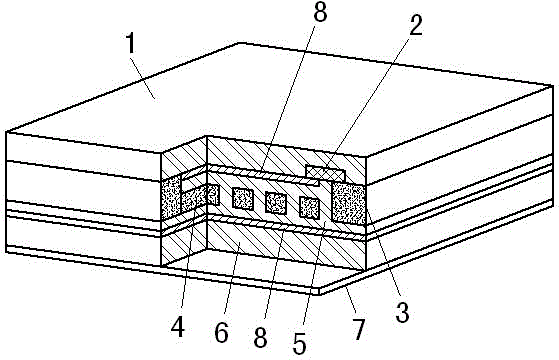

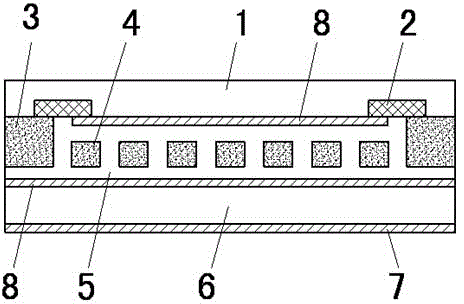

[0026] In specific implementation, use such as Figure 1~3 As shown, different effects can be obtained by changing the structure of the P+ buried layer 4 . It can be made into a series of products with different physical characteristics of current limiting control. The P+ buried layer 4 can be realized by ion influx or buried layer diffusion process.

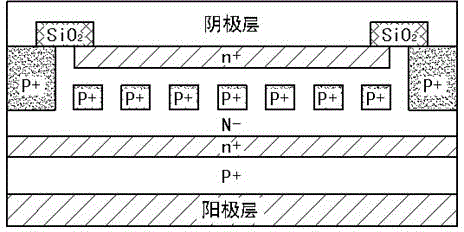

[0027] The specific method is: diffuse a layer of n+ layer on the silicon substrate with P+ impurities, perform N- epitaxy on the n+ layer, diffuse P+ impurities on the N- epitaxial layer, and then perform the second epitaxy to form a P+ buried layer. The diffusion wall of P+ impurity is diffused around the epitaxial layer, and the P+ buried layer is connected with the P+ diffusion wall. The whole forms a Figure 6 The bottom PN junction and multi-N-channel parallel connection self-adjustable JFET field effect transistor structure, the field effect transistor is similar to a multi-N-channel JFET with a common gate (P+buri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com