Insulating composition, insulating article, preparation method and electrical cable accessory thereof

A technology of cable accessories and compositions, applied in the field of insulating compositions, can solve the problems of complex process, high cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0088] This example shows the effect of silane coupling agents on elongation at break.

[0089] The specific silane coupling agent KH450 with two hydrolyzable groups is used for the surface treatment of BT.

[0090] In a weight ratio of 1:10, KH450 was dissolved in an amount of 1 wt% of BT in a solution of 10 wt% water in ethanol (deionized water / ethanol = 1:9 by weight) to obtain 9 wt% KH450 solution. Spray the solution evenly on the surface of the BT. Then, the sprayed BT was dried in an oven at 80 °C for 3 h to remove solvent and moisture. 20 parts by volume of treated BT with 80 parts by volume of silicone rubber and 0.56 parts by volume of crosslinker 2,5-dimethyl-2,5-bis(tert-butylperoxy) through two roller mills (Model X(S)K-160, manufactured by Shanghai Rubber Machinery Factory, China) was mixed. The mixture was then molded into a plate with a size of 20 mm × 20 mm × 2 mm, and passed through a flat press vulcanizer (manufactured by Dongguan Hsin-chi Jingmi Machiner...

example 6-8

[0095] The procedure of Example 1 was repeated except that the components were used in the amounts shown in Table 2. In Example 8, BST was used in place of BT and subjected to the same surface treatment process. Samples were evaluated by testing as described above. The test results of dielectric constant and breakdown strength are shown in Table 2. The results of Example 1 are also listed in Table 2 for comparison.

[0096] Table 2

[0097]

[0098] These examples show the effect of BT and BST loading on dielectric constant and breakdown strength. BT and BST are ferroelectric ceramics with high dielectric constant and good insulation properties. By adding ferroelectric ceramics BT or BST to silicone rubber, the dielectric constant (ε) significantly increases with the concentration of ferroelectric ceramics. Meanwhile, unlike the case of using a conventional material with high ε, the breakdown strength is still maintained at 15 kV or higher, exhibiting good insulation...

example 9

[0100] A small amount of zinc oxide whiskers was used in this example. The process was the same as in Example 1, except that the components shown in Table 3 were used. Table 3 shows the test results of dielectric constant and breakdown strength.

[0101] table 3

[0102]

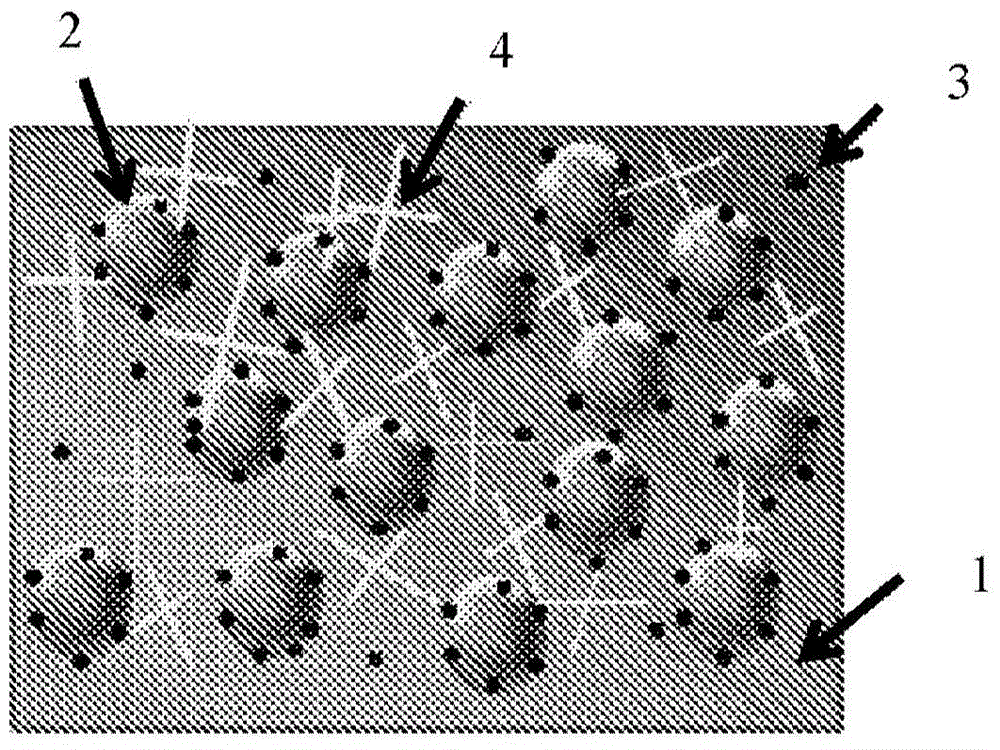

[0103] ZnO whiskers have a cross-shaped fork morphology and are semiconducting. The unique morphology connects BTs to form a network, which is beneficial to obtain a high dielectric constant while maintaining a breakdown strength greater than 15 kV. Compared to Example 1, the BT loading in Example 9 is lower, yet due to the presence of ZnO whiskers, the dielectric constant is higher and at the same time the breakdown strength remains at 15 kV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com