Protective cover of powder metallurgy press

A powder metallurgy and protective cover technology is applied in the field of protective devices to achieve the effects of reduced consumables, simple structure, convenient processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

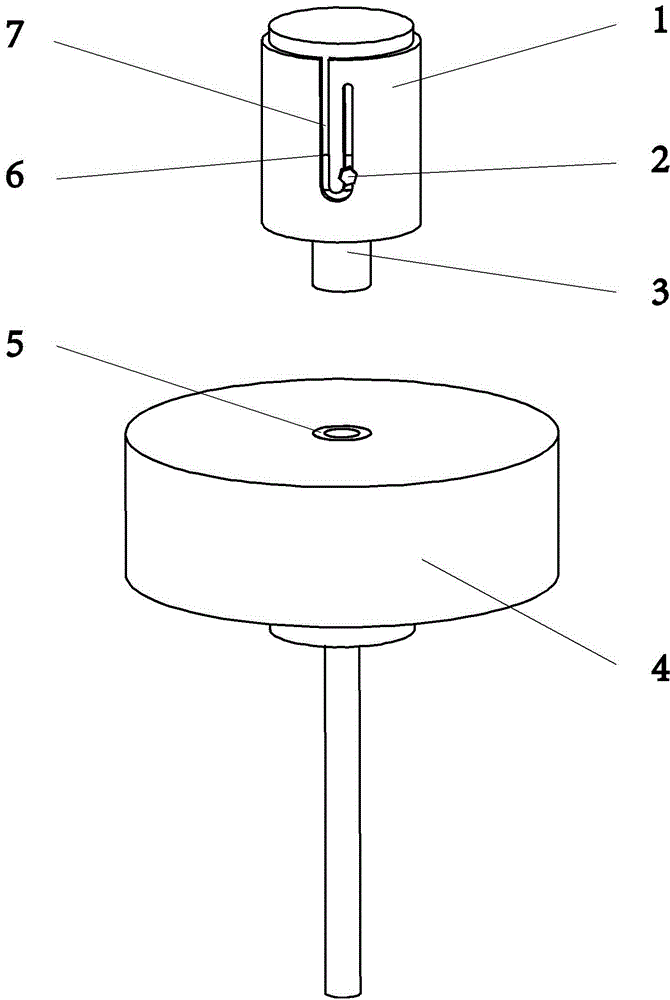

[0013] The reference signs in the drawings of the description include: protective cover 1, bolt 2, upper die punch 3, female die 4, lower die punch 5, U-shaped chute 6, pad 7.

[0014] The embodiment is basically as attached figure 1 Shown:

[0015] Powder metallurgy press protective cover 1, including the protective cover 1, the protective cover 1 is made of a 5mm transparent acrylic plate, which is a cylinder of Ф110*Ф100*120mm, and the protective cover 1 is cut with two openings at one end along the direction parallel to the axis U-shaped chute 6, two U-shaped chutes 6 are symmetrical to the center of the cross section of the protective cover 1, one end of the U-shaped chute 6 is an opening, the top of the blind port and the bottom end of the U-shaped chute 6 are tangential circular grooves, The distances from the corresponding ends of the protective cover 1 are 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com