Outer ring cover body of steering wheel

A steering wheel and trap technology, which is applied to the steering control, hand wheel and other directions installed on the car, can solve the problems of high temperature resistance, environmental protection, and no recycling, and achieves a simple outer trap body and increased availability. , the effect of relieving fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation embodiment of formula I polymer:

[0042]1) In a 250mL round-bottomed three-neck flask, add 1,5-naphthyridine (30mmol), potassium iodide (50mmol), potassium iodate (50mmol) and glacial acetic acid (150mL), stir at room temperature to dissolve, and then heat to 80°C React for 6 hours. Cool to room temperature, filter, and the filter cake is watered successively, saturated with Na 2 CO 3 , saturated Na 2 S 2 o 3 Washed thoroughly with water to obtain a solid product in the form of a white solid.

[0043] 2) In a 100mL round-bottomed three-neck flask, add step 1) product (4mmol), 2-methyl-3-butyn-2-alcohol (12mmol) and NEt 3 (40mL), stirred, pumped twice, then degassed for 30 minutes, added Pd(PPh 3 ) 2 Cl 2 (0.1 mmol), PPh 3 (0.3mmol) and CuI (0.8mmol), heated under reflux to react overnight, TLC showed that the reaction was complete, and the reaction was terminated. Cool to room temperature, filter, and wash the precipitate three times with E...

Embodiment 1

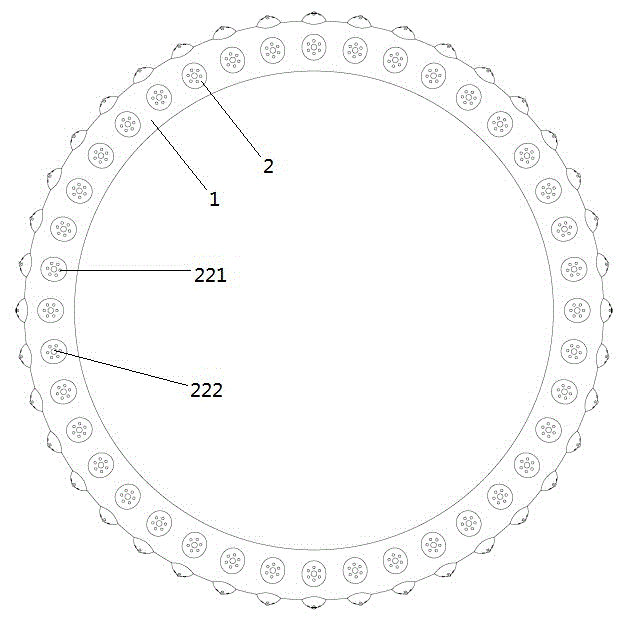

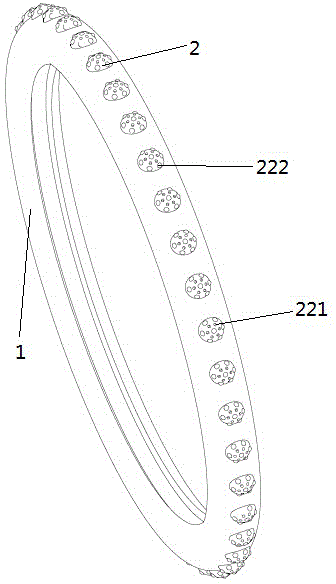

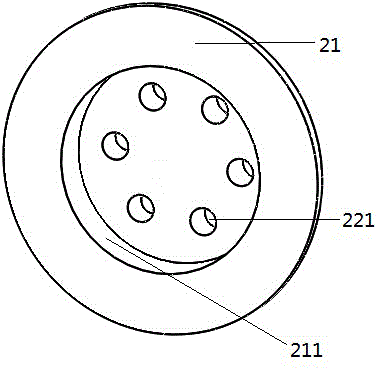

[0052] Such as figure 1 As shown, the outer ring cover body for the steering wheel includes an annular elastic mesh or non-woven fabric ventilation layer 1, and one or more massage parts 2 that are heated, melted, bonded, inlaid or glued on the ventilation layer 1; The massaging member 2 includes a supporting portion 21 and a massaging portion 22 adjacent to each other.

[0053] The setting of the ring-shaped elastic mesh or non-woven fabric ventilation layer 1 of this scheme can increase the friction between the driver's palm and the outer ring casing when driving the vehicle, avoid slipping between the palm and the outer ring casing, and ventilate Layer 1 is made of elastic mesh or non-woven fabric, which can absorb sweat from the palm of the driver and avoid slipping caused by sweat. The elastic mesh or non-woven fabric has air permeability, which increases the air flow while absorbing sweat The circulation of the driver's sweat is alleviated, which not only improves the s...

Embodiment 2

[0064] The outer ring casing body of the steering wheel is the same as in Embodiment 1, the difference is that:

[0065] In step (1), apply a release agent to the mold of the massage part before casting, and control the heating temperature at 25°C. The particle size range of additives is 0.8-5 microns; among them, the particles of 0.8-1 microns account for 40% of the total weight of solid additives; the particles of 1-2 microns account for 30% of the total weight of solid additives; the balance of particles of 5 microns ;

[0066] The second cooling temperature in step (3) is 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com