Natural graphite ore stripping and purifying method

A technology of natural graphite and purification method, which is applied in the field of natural graphite ore stripping and purification, can solve the problems of high technical difficulty, waste of resources and high cost in the purification of cryptocrystalline graphite, and achieves the effects of low cost, less pollutant generation and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

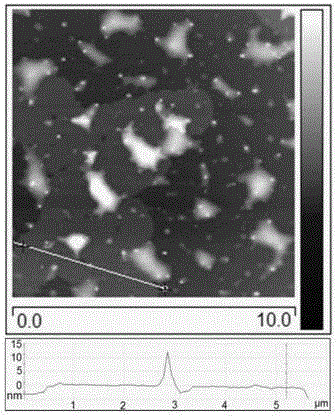

[0058] With aphanitic graphite ore powder 10kg (fixed carbon content is 43.2%, 200 orders), H 2 o 2 (1.0kg), ammonium formate (0.3kg) and H 2 O (30kg) is mixed and stirred evenly and loaded into the reaction tank, soaked statically for 5h, and stirred for 1h under UV light, and the graphite ore slurry is sent into a filter press for pressure filtration; the filter cake is mixed with 1.0kg (NH 4 ) 2 CO 3 、20L H 2 O mixed and stirred evenly, put into a 50L airtight reactor, and soaked statically for 32h. Start the reactor heating equipment, heat to 80°C for 5 hours, and cycle heating and cooling for 5 times. Send the heated graphite ore slurry into a filter press for pressure filtration, mash the filter cake, transfer it to an ultrasonic device, add 30L of water for ultrasonic peeling for 12 hours, transfer the ultrasonic graphite ore slurry into a 100L container, add 50L of water, stirred for 0.5h, static for 6h.

[0059] Centrifuge the upper dispersion liquid to obtain ...

Embodiment 2

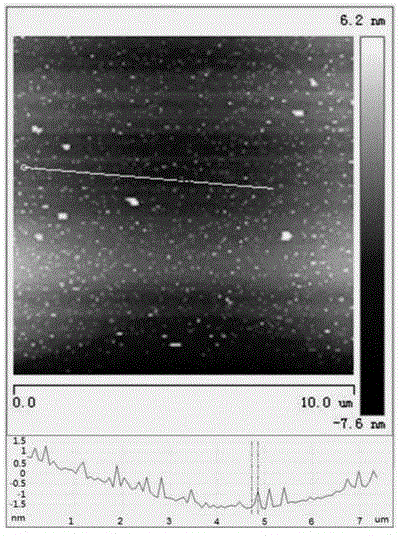

[0061] With aphanitic graphite ore powder 10kg (fixed carbon content is 65.3%, 300 orders), (NH 4 ) 2 S 2 o 8 (0.5kg), acetamide (0.1kg) and H 2 O (20kg) was mixed and stirred evenly into the reaction tank, soaked statically for 12 hours, and visible light was illuminated for 1.5 hours under stirring, and the graphite ore slurry was sent to a filter press for pressure filtration; the filter cake was mixed with 3.0kg NH 4 HCO 3 、20L H 2 O mixed and stirred evenly, put into a 50L airtight reactor, and soaked statically for 24h. Start the reactor heating equipment, heat to 100°C for 4 hours, and cycle heating and cooling for 3 times. Send the heated graphite ore slurry into a filter press for pressure filtration, crush the filter cake, transfer it to an ultrasonic device, add 40L of water for ultrasonic peeling for 6 hours, transfer the ultrasonic graphite ore slurry into a 100L container, add 50L of water, stirred for 0.5h, static for 6h.

[0062] Centrifuge the upper di...

Embodiment 3

[0064] Aphanitic graphite ore powder 10kg (fixed carbon content is 78.3%, 200 mesh), HNO 3 (0.8kg), phthalimide (1.5kg) and H 2 O (20kg) is mixed and stirred evenly and loaded into the reaction tank, statically soaked for 5h, and visible light is illuminated for 2h under stirring, and the graphite ore slurry is sent into a filter press for pressure filtration; the filter cake is mixed with 5kg (NH 4 ) 2 CO 3 、30L H 2 O mixed and stirred evenly, put into a 50L reactor (open), and soaked statically for 30h. Start the reactor heating equipment, heat to 90°C for 5 hours, and cycle heating and cooling for 4 times. Send the heated graphite ore slurry into a filter press for pressure filtration, crush the filter cake, transfer it to an ultrasonic device, add 30L of water for ultrasonic peeling for 6 hours, transfer the ultrasonic graphite ore slurry into a 100L container, add 50L of water, stirred for 0.5h, static for 6h.

[0065] Centrifuge the upper dispersion to obtain graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com