Method for preparing silicon dioxide core-shell materials with core-shell spacing

A silicon dioxide, core-shell technology, applied in the direction of silicon dioxide, silicon oxide, etc., to achieve the effect of simple preparation method and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

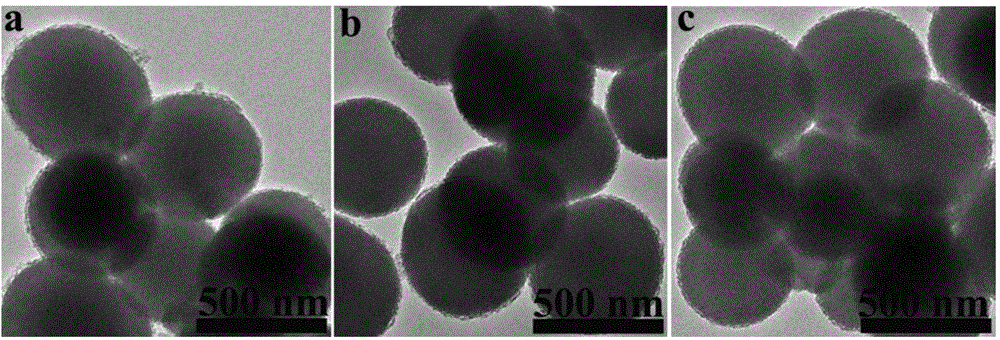

Embodiment example 1

[0049] Put a 250mL three-neck flask in an oil bath, add 6mL distilled water, 8mL ammonia water and 100mL absolute ethanol; add 4mL TEOS dropwise to the mixed solution under stirring, and stir at 40°C for 12h. After cooling, the obtained white precipitate solution was centrifuged, and the obtained precipitate was washed repeatedly with distilled water. Dry the obtained precipitate at 40 °C for 12 h to obtain SiO with a particle size of about 450 nm 2 nanospheres.

[0050] 1.0g of the above prepared SiO 2 Nanospheres, 25mL toluene in a 100mL three-necked flask and place the three-necked flask in an oil bath, stir evenly by magnetic force, add 3.0mL APTES dropwise to the flask, N 2 Under the conditions, stir and react at 95°C for 18h, centrifuge, wash and dry to obtain amino-modified SiO 2 -NH 2 .

[0051] Add 0.8g SiO to a 100mL three-neck flask 2 -NH 2 , 15mL toluene, 1mL triethylamine, ultrasonic 10min, put the flask in a low-temperature reaction bath, mix well, stir at...

Embodiment example 2

[0059] Put a 250mL three-neck flask in an oil bath, add 6mL distilled water, 8mL ammonia water and 100mL absolute ethanol; add 4mL TEOS dropwise to the mixed solution under stirring, and stir at 40°C for 12h. After cooling, the obtained white precipitate solution was centrifuged, and the obtained precipitate was washed repeatedly with distilled water. Dry the obtained precipitate at 40 °C for 12 h to obtain SiO with a particle size of about 450 nm 2 nanospheres.

[0060] 1.0g of the above prepared SiO 2 Nanospheres, 25mL toluene in a 100mL three-necked flask and place the three-necked flask in an oil bath, stir evenly by magnetic force, add 3.0mL APTES dropwise to the flask, N 2 Under the conditions, stir and react at 95°C for 18h, centrifuge, wash and dry to obtain amino-modified SiO 2 -NH 2 .

[0061] Add 0.4g SiO to a 100mL three-neck flask 2 -NH 2 , 15mL toluene, 1mL triethylamine, ultrasonic 10min, put the flask in a low-temperature reaction bath, mix well, stir at...

Embodiment example 3

[0069] Put a 250mL three-neck flask in an oil bath, add 6mL of distilled water, 8mL of ammonia water and 100mL of absolute ethanol; add 4mL of TEOS dropwise to the mixed solution with stirring, and stir at 40°C for 12h. After cooling, the obtained white precipitate solution was centrifuged, and the obtained precipitate was washed repeatedly with distilled water. Dry the obtained precipitate at 40 °C for 12 h to obtain SiO with a particle size of about 450 nm 2 nanospheres.

[0070] 1.0g of the above prepared SiO 2 Nanospheres, 25mL of toluene in a 100mL three-necked flask and place the three-necked flask in an oil bath, and after magnetically stirring evenly, add 3.0mL APTES dropwise to the flask, N 2 Under the conditions, stir and react at 95°C for 18h, centrifuge, wash and dry to obtain amino-modified SiO 2 -NH 2 .

[0071] Add 0.4g SiO to a 100mL three-neck flask 2 -NH 2 , 15mL toluene, 1mL triethylamine, ultrasonic 10min, put the flask in a low-temperature reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com