Heat-resisting, scraping-resisting and high-transmittance PMMA alloy resin and preparation method thereof

A high transmittance, alloy resin technology, applied in the field of polymer materials, can solve the problems of complex equipment, strict process requirements, unfavorable mass production, etc., and achieve the effect of simple preparation process, high transparency, and favorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

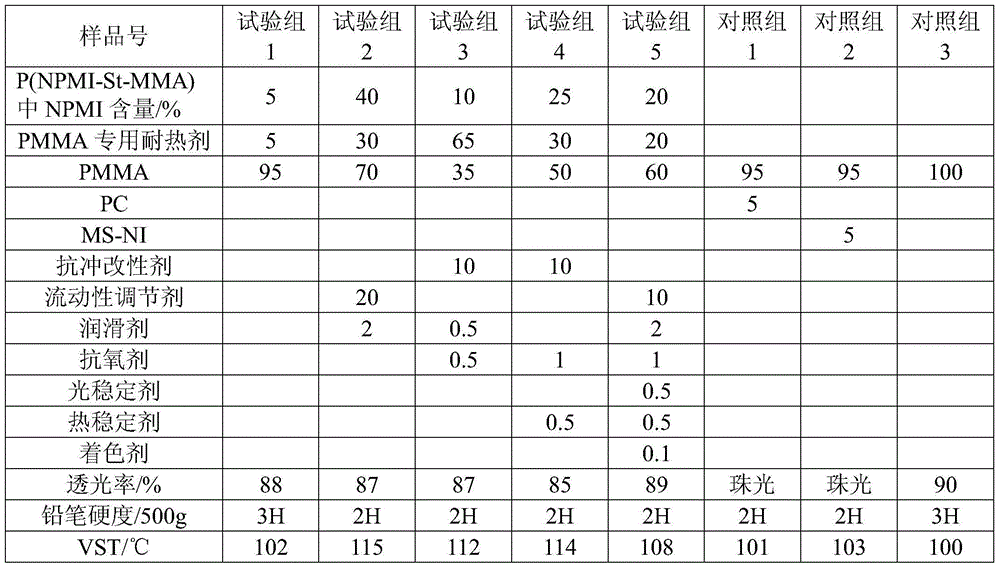

Embodiment 1

[0020] Embodiment 1 Preparation of a heat-resistant, scratch-resistant, high-transmittance PMMA alloy resin of the present invention (1)

[0021] Raw materials: 95 parts of polymethyl methacrylate, 5 parts of special heat-resistant agent for PMMA. Wherein, the NPMI content of P(NPMI-St-MMA) in the special heat-resistant agent for PMMA is 5%.

[0022] Preparation process: Put the above-mentioned raw materials in a high-speed mixer according to the formula and mix them evenly, and then send them into the twin-screw extruder through a metering device. Under the conveying, shearing and mixing of the screws, the materials are melted and compounded, and then After the steps of extrusion, drawing, cooling and pelletizing, it can be obtained. Wherein the extrusion temperature is 200°C.

Embodiment 2

[0023] Embodiment 2 Preparation of a heat-resistant, scratch-resistant, high-transmittance PMMA alloy resin of the present invention (2)

[0024] Raw materials: 10 parts of polymethyl methacrylate, 90 parts of special heat-resistant agent for PMMA. Wherein, the NPMI content of P(NPMI-St-MMA) in the special heat-resistant agent for PMMA is 20%.

[0025] Preparation process: Put the above-mentioned raw materials in a high-speed mixer according to the formula and mix them evenly, and then send them into the twin-screw extruder through a metering device. Under the conveying, shearing and mixing of the screws, the materials are melted and compounded, and then After the steps of extrusion, drawing, cooling and pelletizing, it can be obtained. Wherein the extrusion temperature is 240°C.

Embodiment 3

[0026] Example 3 Preparation of a heat-resistant, scratch-resistant, high-transmittance PMMA alloy resin of the present invention (3)

[0027] Raw materials: 70 parts of polymethyl methacrylate, 30 parts of special heat-resistant agent for PMMA, 20 parts of flow regulator, and 2 parts of lubricant. Wherein, the NPMI content of P(NPMI-St-MMA) in the special heat-resistant agent for PMMA is 40%.

[0028] Preparation process: Put the above-mentioned raw materials in a high-speed mixer according to the formula and mix them evenly, and then send them into the twin-screw extruder through a metering device. Under the conveying, shearing and mixing of the screws, the materials are melted and compounded, and then After the steps of extrusion, drawing, cooling and pelletizing, it can be obtained. Wherein the extrusion temperature is 270°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com