Novel low-temperature curing epoxy powder paint

An epoxy powder and coating technology, applied in the field of coatings, can solve the problems of high curing temperature, narrow application range, and large energy consumption, and achieve the effects of low curing temperature, wide application range, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

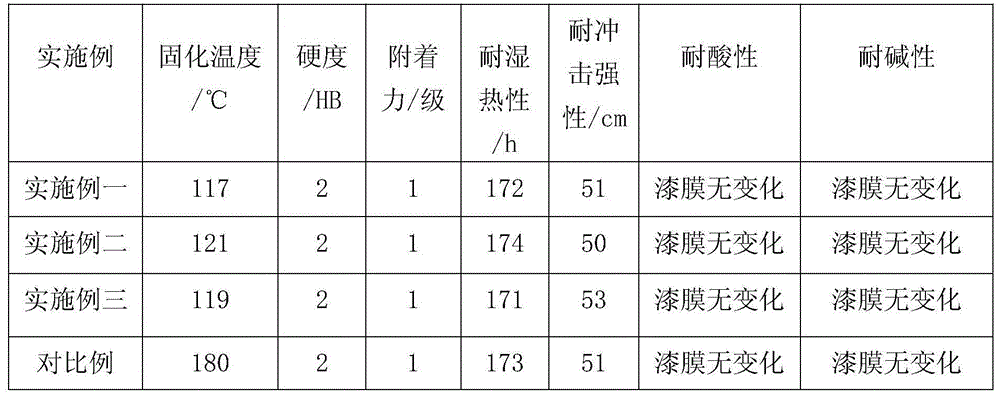

Examples

Embodiment 1

[0017] A new type of low-temperature curing epoxy powder coating, which is composed of the following components by weight: 48 parts of epoxy resin, 8 parts of modified crosslinking agent, 0.5 part of catalyst, 0.8 part of leveling agent, 0.4 part of benzoin, titanium dioxide 8 parts, 0.4 parts of wetting agent, 16 parts of precipitated barium sulfate, 6 parts of active silica powder and 0.2 parts of wax powder.

[0018] The epoxy resin is bisphenol A type epoxy resin; the modified cross-linking agent is a phenolic modified cross-linking agent; the catalyst is dimethylimidazole; the titanium dioxide is red gold type titanium chalk.

[0019] A preparation method of a novel low-temperature curing epoxy powder coating comprises the following steps:

[0020] (1), first mix epoxy resin, modified crosslinking agent, catalyst, leveling agent, benzoin, titanium dioxide, wetting agent, precipitated barium sulfate, active silicon micropowder and wax powder to obtain a mixture;

[0021]...

Embodiment 2

[0027] A new type of low-temperature curing epoxy powder coating, the coating is composed of the following components by weight: 50 parts of epoxy resin, 9 parts of modified crosslinking agent, 0.75 parts of catalyst, 1.0 parts of leveling agent, 0.5 parts of benzoin, titanium dioxide 10 parts, 0.5 parts of wetting agent, 20 parts of precipitated barium sulfate, 8 parts of active silica powder and 0.25 parts of wax powder.

[0028] The epoxy resin is bisphenol A type epoxy resin; the modified cross-linking agent is a phenolic modified cross-linking agent; the catalyst is dimethylimidazole; the titanium dioxide is red gold type titanium chalk.

[0029] A preparation method of a novel low-temperature curing epoxy powder coating comprises the following steps:

[0030] (1), first mix epoxy resin, modified crosslinking agent, catalyst, leveling agent, benzoin, titanium dioxide, wetting agent, precipitated barium sulfate, active silicon micropowder and wax powder to obtain a mixtur...

Embodiment 3

[0037] A new type of low-temperature curing epoxy powder coating, the coating is composed of the following components by weight: 52 parts of epoxy resin, 10 parts of modified crosslinking agent, 1.0 parts of catalyst, 1.2 parts of leveling agent, 0.6 parts of benzoin, titanium dioxide 12 parts, 0.6 parts of wetting agent, 24 parts of precipitated barium sulfate, 10 parts of active silica powder and 0.3 parts of wax powder.

[0038] The epoxy resin is bisphenol A type epoxy resin; the modified cross-linking agent is a phenolic modified cross-linking agent; the catalyst is dimethylimidazole; the titanium dioxide is red gold type titanium chalk.

[0039] A preparation method of a novel low-temperature curing epoxy powder coating comprises the following steps:

[0040] (1), first mix epoxy resin, modified crosslinking agent, catalyst, leveling agent, benzoin, titanium dioxide, wetting agent, precipitated barium sulfate, active silicon micropowder and wax powder to obtain a mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com