Environment-friendly water-borne acrylic-modified epoxy baking varnish

A water-based acrylic, environmentally friendly technology, applied in the field of baking varnish, can solve problems such as poisoning, environmental pollution, and hazards, and achieve the effects of good wear resistance, high toughness, and high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

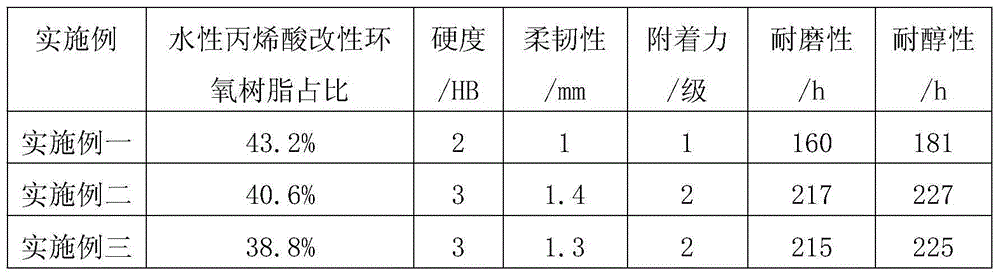

Examples

Embodiment 1

[0017] An environment-friendly water-based acrylic modified epoxy baking varnish, which is composed of the following components by weight: 15 parts of dipropylene glycol methyl ether, 0.5 parts of isopropanol, 6 parts of amino resin, and 42 parts of water-based acrylic modified epoxy resin , 0.6 parts of dispersant, 0.2 parts of defoamer, 0.45 parts of leveling agent, 0.35 parts of pH regulator, 30 parts of white slurry, 2 parts of deionized water and 0.1 part of thickener.

[0018] Described pH adjusting agent is sodium hydroxide solution.

[0019] A preparation method of an environment-friendly water-based acrylic acid modified epoxy baking varnish, comprising the following steps:

[0020] (1) Add dipropylene glycol methyl ether, isopropanol, amino resin, water-based acrylic modified epoxy resin, dispersant, defoamer, and leveling agent into the paint mixing ax in sequence, and the high-speed disperser operates at 1000r / min Disperse for 25 minutes;

[0021] (2), add the wh...

Embodiment 2

[0026] An environment-friendly water-based acrylic modified epoxy baking varnish, which is composed of the following components by weight: 17 parts of dipropylene glycol methyl ether, 0.6 parts of isopropanol, 7 parts of amino resin, and 43 parts of water-based acrylic modified epoxy resin , 0.8 parts of dispersant, 0.35 parts of defoamer, 0.5 parts of leveling agent, 0.4 parts of pH regulator, 33 parts of white slurry, 3 parts of deionized water and 0.15 parts of thickener.

[0027] Described pH adjusting agent is sodium hydroxide solution.

[0028] A preparation method of an environment-friendly water-based acrylic acid modified epoxy baking varnish, comprising the following steps:

[0029] (1) Add dipropylene glycol methyl ether, isopropanol, amino resin, water-based acrylic modified epoxy resin, dispersant, defoamer, and leveling agent to the paint mixing ax in sequence, and the high-speed disperser operates at 1100r / min Disperse for 30 minutes;

[0030] (2), add the whi...

Embodiment 3

[0035] An environment-friendly water-based acrylic modified epoxy baking varnish, which is composed of the following components by weight: 18 parts of dipropylene glycol methyl ether, 0.7 parts of isopropanol, 8 parts of amino resin, and 44 parts of water-based acrylic modified epoxy resin , 1.1 parts of dispersant, 0.5 parts of defoamer, 0.55 parts of leveling agent, 0.45 parts of pH regulator, 36 parts of white slurry, 4 parts of deionized water and 0.2 parts of thickener.

[0036] Described pH adjusting agent is sodium hydroxide solution.

[0037] A preparation method of an environment-friendly water-based acrylic acid modified epoxy baking varnish, comprising the following steps:

[0038] (1) Add dipropylene glycol methyl ether, isopropanol, amino resin, water-based acrylic modified epoxy resin, dispersant, defoamer, and leveling agent into the paint mixing ax in sequence, and the high-speed disperser operates at 1200r / min Disperse for 35 minutes;

[0039] (2), add the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com