A kind of low carbon nano bainitic steel and preparation method thereof

A bainitic steel and carbon nanotechnology, applied in the field of low-carbon nanoscale bainitic steel and its preparation, can solve the problems of difficult promotion of nano-bainitic steel, difficult machining, poor welding performance, etc., and achieve Wide range of industrial application prospects, low cost of alloying, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

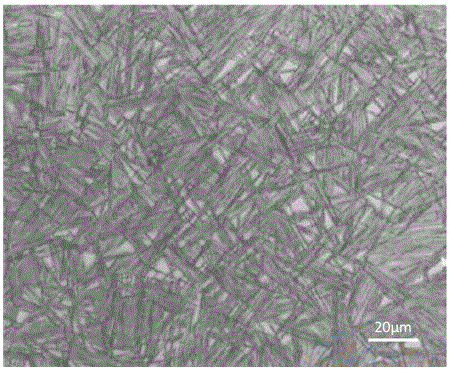

Image

Examples

Embodiment 1

[0035] The composition and weight percentage of the steel in the embodiment of the present invention are: C: 0.49%, Si: 1.58%, Mn: 2.80%, Mo: 0.91%, Al: 3.1%, S: 0.0016%, P: 0.0062%, and the rest For Fe.

[0036] The preparation method is as follows: heat the steel at a rate of 15°C / s to the austenitization temperature of 900°C and hold it for 5 minutes, then carry out austenitic deformation, then quench to 280°C, and then carry out low-temperature constrained deformation, and the cooling rate is 0.5°C / min , the deformation rate is 0.2s -1 , and finally quenched to room temperature.

[0037] According to GB / T228.1-2010 "Metallic Materials Tensile Test Part 1: Room Temperature Test Method", the obtained multi-phase steel products are inspected, and the tensile test is carried out on the Zwick T1-FR020TN A50 standard tensile testing machine. After testing, the tensile strength Rm of the steel is 1845MPa, and the yield strength Rp 0.2 It is 1433MPa, and the total elongation i...

Embodiment 2

[0039] The composition and weight percentage of the steel in the embodiment of the present invention are: C: 0.43%, Si: 1.38%, Mn: 2.61%, Mo: 0.82%, Al: 3.5%, S: 0.0015%, P: 0.0064%, and the rest For Fe.

[0040] The preparation method is as follows: heat the steel at a rate of 15°C / s to the austenitizing temperature of 900°C for 5 minutes, then conduct austenitic deformation, then quench to 300°C, and then carry out low-temperature constrained deformation, and the cooling rate is 0.7°C / min , the deformation rate is 0.5s -1 , and finally quenched to room temperature.

[0041] According to GB / T228.1-2010 "Metallic Materials Tensile Test Part 1: Room Temperature Test Method", the obtained multi-phase steel products are inspected, and the tensile test is carried out on the Zwick T1-FR020TN A50 standard tensile testing machine. After testing, the tensile strength Rm of the steel is 1723MPa, and the yield strength Rp 0.2 It is 1379MPa, and the total elongation is 14.2%.

Embodiment 3

[0043] The composition and weight percentage of the steel in the embodiment of the present invention are: C: 0.40%, Si: 1.85%, Mn: 3.10%, Mo: 0.65%, Al: 2.9%, S: 0.0013%, P: 0.0056%, and the rest For Fe.

[0044] The preparation method is as follows: heat the steel at a rate of 15°C / s to the austenitization temperature of 900°C and hold it for 5 minutes, then carry out austenitic deformation, then quench to 320°C, and then carry out low-temperature constrained deformation, and the cooling rate is 1.0°C / min , the deformation rate is 0.5s -1 , and finally quenched to room temperature.

[0045] According to GB / T228.1-2010 "Metallic Materials Tensile Test Part 1: Room Temperature Test Method", the obtained multi-phase steel products are inspected, and the tensile test is carried out on the Zwick T1-FR020TN A50 standard tensile testing machine. After testing, the tensile strength Rm of the steel is 1785MPa, and the yield strength Rp 0.2 It is 1336MPa, and the total elongation i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com