An over-temperature protection circuit

An over-temperature protection circuit and circuit technology, applied in emergency protection circuit devices, circuit devices, emergency protection devices with automatic disconnection, etc., can solve the problems of complex circuit structure, low output accuracy, and large layout area of hysteresis comparators. , to achieve the effect of high output precision, flexible setting and preventing thermal oscillation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

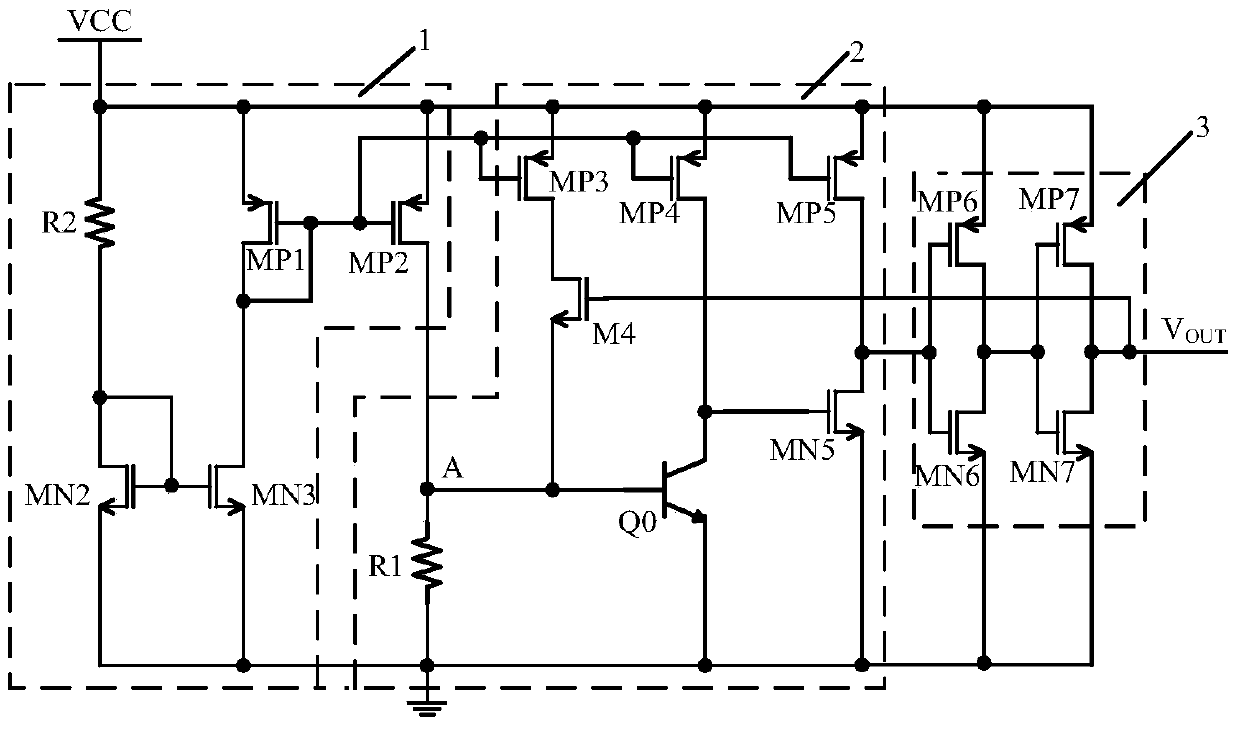

[0025] Such as image 3 As shown, an over-temperature protection circuit includes: a constant current generating circuit 1, an output control circuit 2, and an output shaping circuit 3, wherein,

[0026] The constant current generating circuit 1 includes: a second resistor R2, a second NMOS transistor MN2, a third NMOS transistor MN3, a first PMOS transistor MP1 and a second PMOS transistor MP2, wherein one end of the second resistor R2 is connected to the power supply voltage VCC, and the second The gate of the second NMOS transistor MN2 is connected to the drain, and is connected to the other end of the second resistor R2 and the gate of the third NMOS transistor MN3, and the gate of the first PMOS transistor MP1 is connected to the drain, and is connected to the second PMOS transistor MN3. The gate of the transistor MP2 is connected, the drain of the first PMOS transistor MP1 is connected to the drain of the third NMOS transistor MN3, the sources of the first PMOS transisto...

Embodiment 2

[0043] In embodiment 2 of the present invention, such as Figure 4 As shown, the working principle of the above over-temperature protection circuit is as follows:

[0044] The working principle of this example is similar to that of Example 1, the difference is that the hysteresis control tube M4 in Example 1 is replaced by a PMOS tube by an NMOS tube, and the gates of the PMOS tubes are respectively connected to the gates of the sixth NMOS tube and the sixth PMOS tube. The drains are connected, the source is connected with the drain of the third PMOS transistor, and the drain is connected with the base of the Q0 transistor.

[0045] When the die temperature falls below the thermal shutdown temperature threshold point T 0 At this time, the over-temperature protection outputs a low level, at this time the gate voltage of the M4 tube is high, and the M4 tube is cut off. When the temperature exceeds the thermal shutdown temperature threshold point T 0 At this time, the over-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com