Feather quantized femoral stem

A femoral stem and stem head technology, applied in the field of feathered femoral stems, can solve problems such as loosening, shaking, increasing the load on human bones, and unfavorable attachment of new bone cells, and achieves improved bending and shear resistance. The effect of the fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

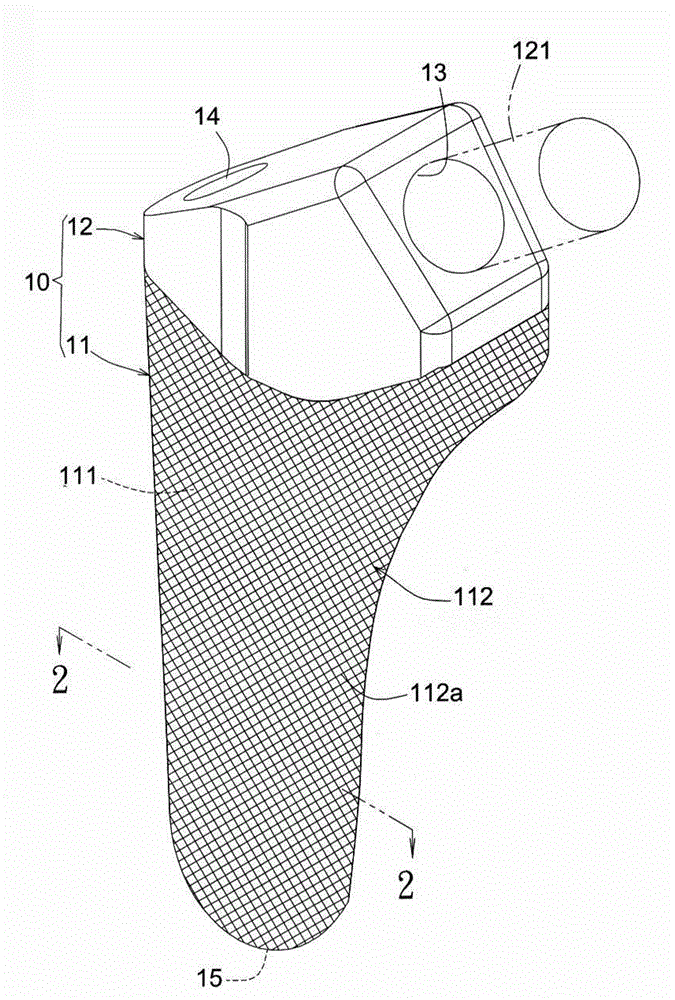

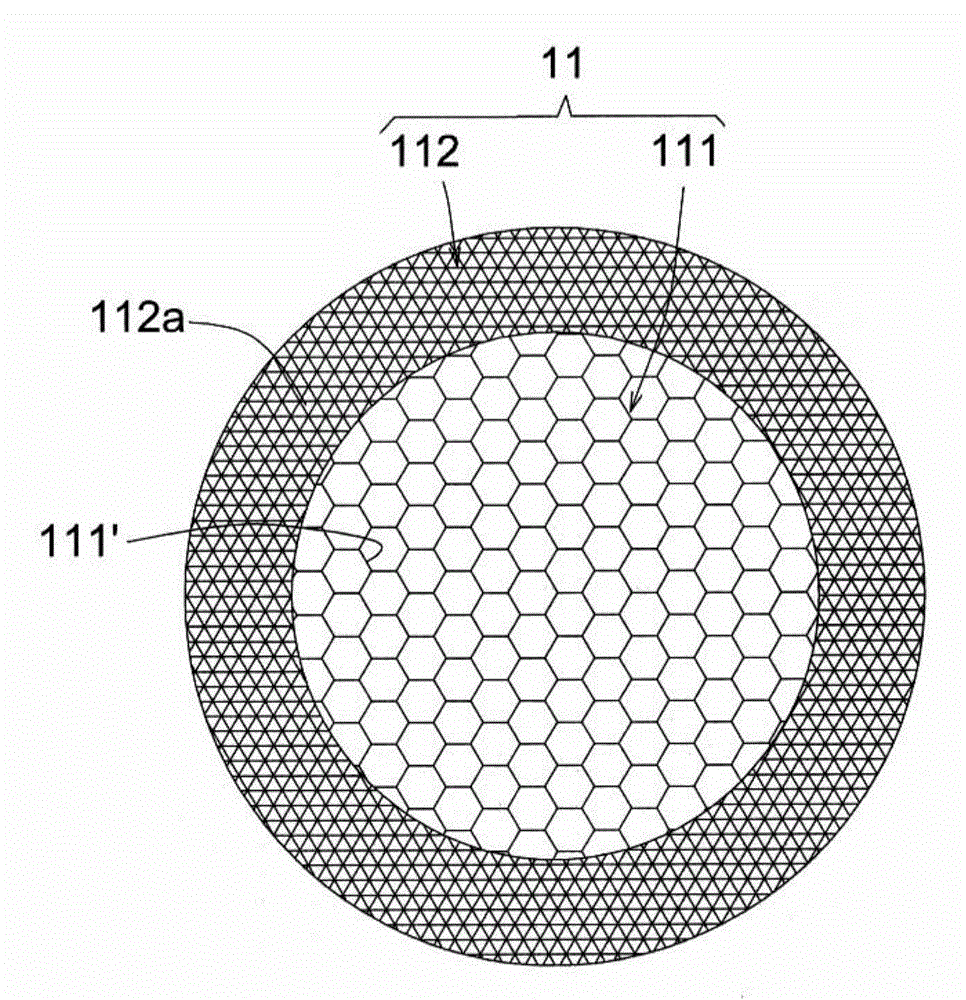

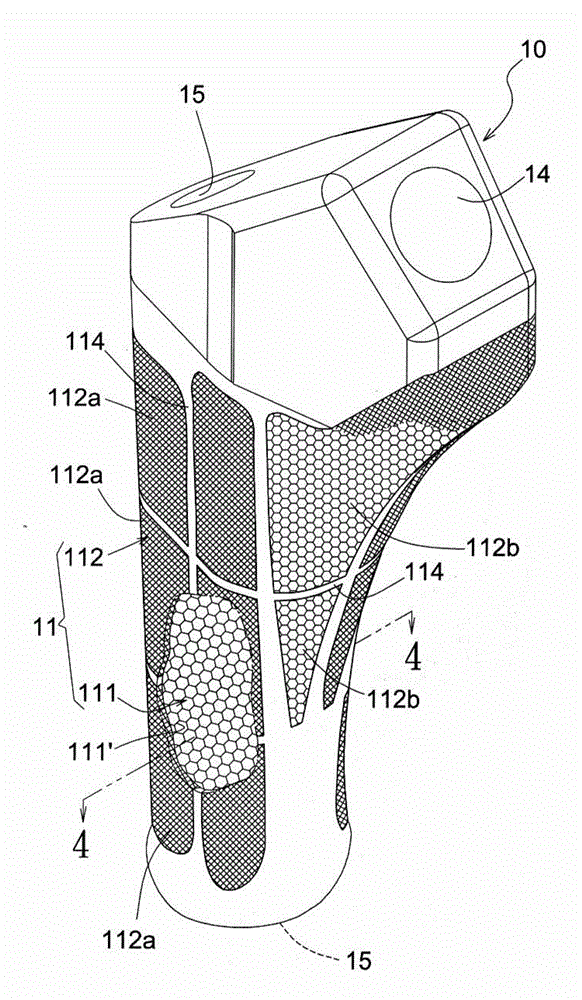

[0035] see figure 1 , figure 2 , Figure 5 ,and Image 6 As shown, the present invention relates to a feathered femoral stem 10, which is integrally formed by metal powder lamination (additive manufacturing or 3D printing), and includes a base column 11, and a handle head is formed on the top of the base column 11 12, and an artificial femoral neck 121 is protruded on the handle 12; wherein the base column 11 includes: at least one inner grid body 111, located in the inner part of the base column 11, and each inner grid body 111 is A hollow-out structure composed of several trabeculae, with several holes 111' stacked on each other; and a fusion layer 112, which surrounds the periphery of the inner mesh body 111, and the fusion layer 112 has at least one area, which is composed of Several micro-beams are composed of a hollow-out outer grid body 112a, and the outer grid body has several micro-holes 112' stacked on each other (such as Figure 5 shown), and let the density of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com