Suppository manufacturing method and suppository manufacturing equipment

A manufacturing method and a technology for manufacturing equipment, which are applied in the direction of making medicines into special physical or ingestible devices, can solve problems such as fragility, high labor intensity, and secondary injury to users, and achieve increased specific surface area, High degree of automation, enhanced effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method of manufacturing a molded suppository, the process comprising:

[0027] a. The medicament is melted and stirred by the melting and stirring tank 7 heated by the spacer, and then sent to the centrifugal spray cooling granulator 11 for spraying. After the external air is dedusted, dehumidified and heated, dry cold air is obtained, and the quantitative feeding is carried out. The device 5 adds fine powder into the dry cold air, and then blows the dry cold air tangentially into the centrifugal spray cooling granulator from the top of the centrifugal spray cooling granulator, so that the mist medicine and the fine powder in the dry cold air are fully mixed , Cooling and granulation after bonding;

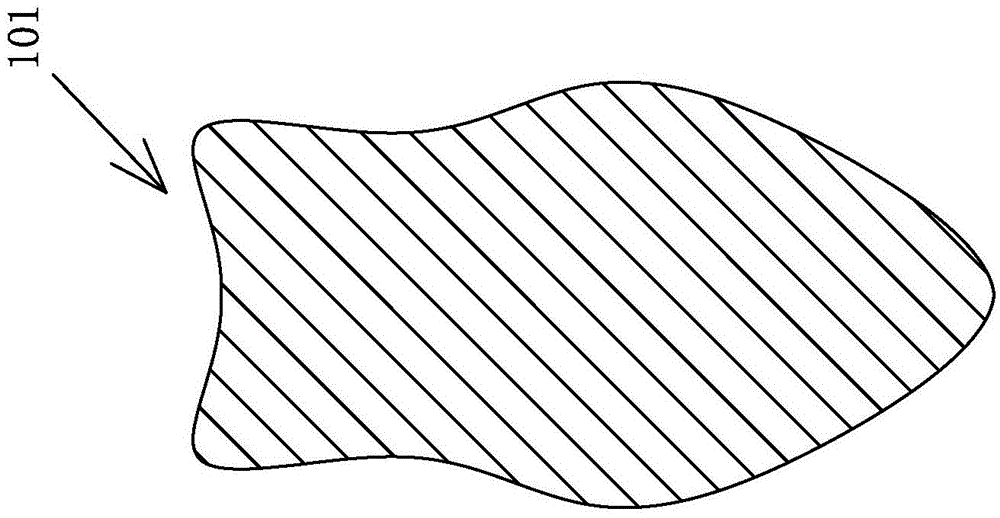

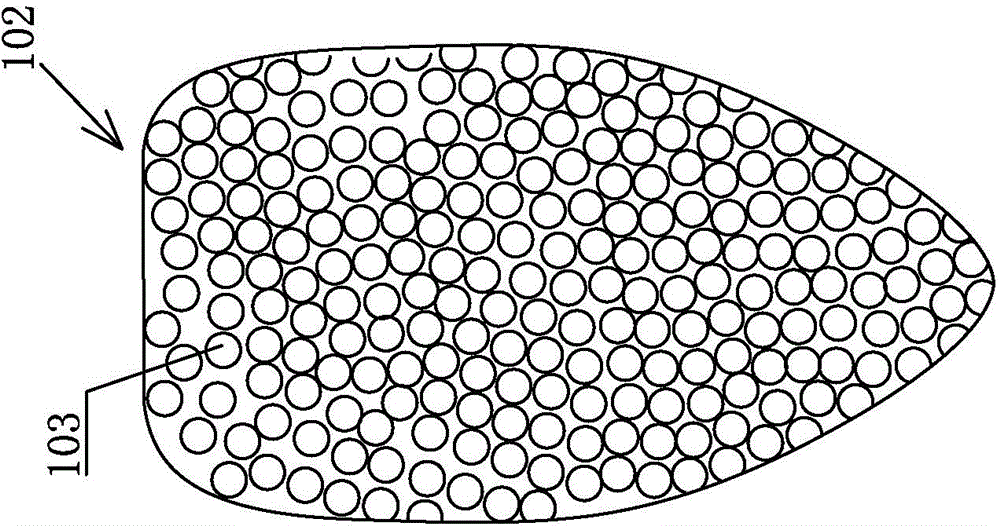

[0028] b. Sieve the medicament granules generated by cooling granulation, and sieve the granules with a particle size between 40-80 mesh as the required medicament granules, and send them into the mold and process them into suppositories by molding; sieve the powder with ...

Embodiment 2

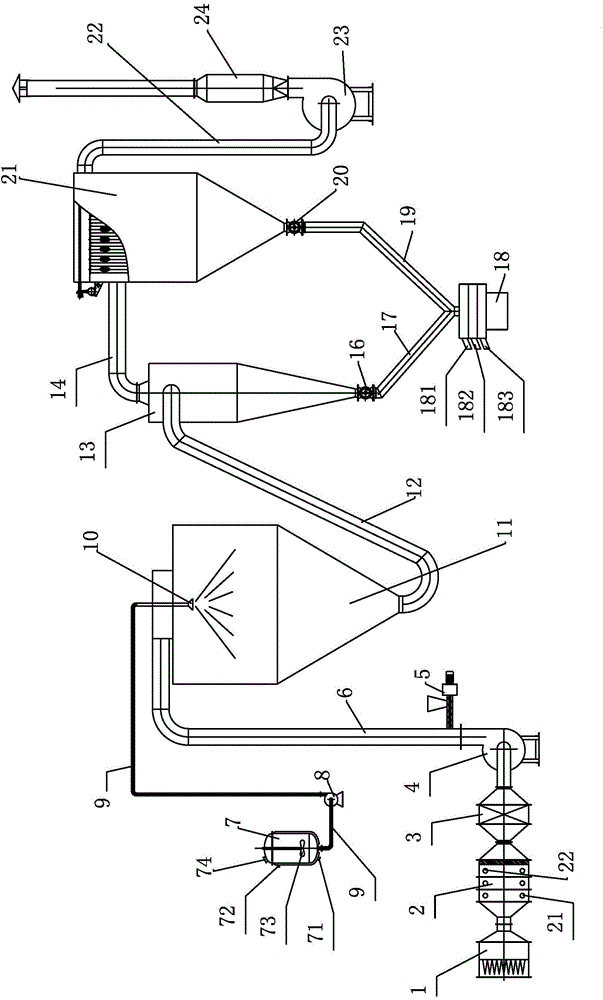

[0032] like image 3 Shown, a kind of suppository manufacturing equipment adopting the molded suppository manufacturing method in the embodiment 1, it comprises: air filter 1, dehumidification cooler 2, heater 3, dehumidification fan 4, quantitative feeder 5, air tube 6. Melting stirring tank 7, peristaltic pump 8, conveying pipe 1 9, atomizing disc 10, centrifugal spray cooling granulator 11, conveying pipe 2 12, cyclone separator 13, conveying pipe 3 14, blower 1 16, conveying Pipe four 17, oscillating screen 18, delivery pipe five 19, blower fan two 20, pulse bag dust filter 21, delivery pipe six 22, exhaust fan 23, muffler 24.

[0033] The air filter 1 used to filter the dust in the air communicates with the dehumidification cooler 2 on the right side through the pipeline, and the dehumidification cooler 2 includes a plurality of cooling water inlets 21 in the lower part and a plurality of cooling water outlets 22 in the upper part, which can The air is dehumidified, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com