Preparation method of molecular imprinting photocatalytic composite material based on 3D graphene/BiOI

A graphene composite and molecular imprinting technology, which is applied in the field of photocatalytic materials, achieves the effect of strong specific and selective degradation ability and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

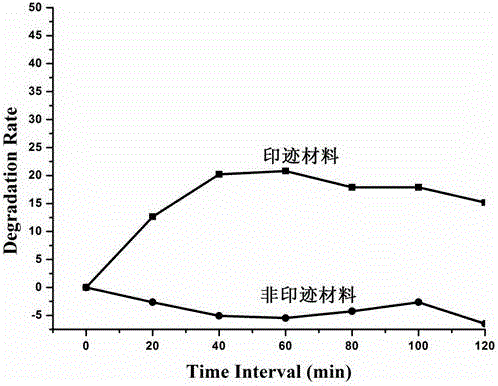

Embodiment 1

[0018] (1) 1.51g Bi(NO 3 ) 3 ·5H 2 O, 0.4 g PVP-K30 and 5 ml HNO 3 (1.0 M) was added to 50 ml distilled water to form solution A; 0.5 g KI, 0.40 g PVP-K30 were added to 60 ml distilled water to form solution B. Solution B was then added dropwise to solution A under magnetic stirring. The resulting mixture was stirred in air for 2 h. Then, the formed yellow precipitate was collected by centrifugation, washed alternately with distilled water and pure ethanol, and dried at 80 °C for 3 h to obtain BiIO;

[0019] (3) Dissolve 0.05g of p-nitrophenol and 17.3 ul of pyrrole into 5.0 ml of methanol: distilled water (1:1, V / V) mixture, and stir the mixture for 30 min in the dark to prepare a pre-self-assembly solution ;

[0020] (4) Suspend 0.5g BiIO in 100 ml of HCl solution (pH=2), deoxidize and sonicate for 30 min to obtain a uniformly dispersed solution. Assembly solution was added to this solution. Then, 2 ml containing 0.27 g FeCl 3 solution (pH=2) was added dropwise to t...

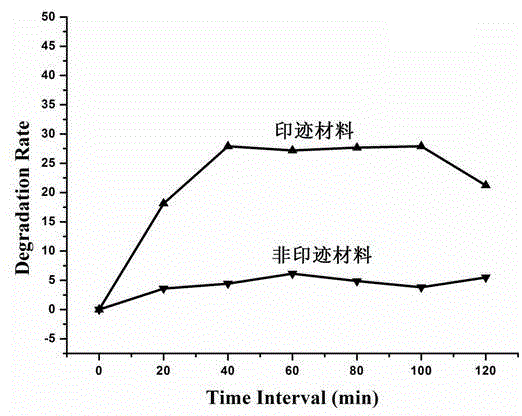

Embodiment 2

[0024] (1) 1.51g Bi(NO 3 ) 3 ·5H 2 O, 0.4g PVP-K30 and 5ml HNO 3 (1.0 M) was added to 50 ml distilled water to form solution A; 0.5 g KI, 0.40 g PVP-K30 were added to 60 ml distilled water to form solution B. Solution B was then added dropwise to solution A under magnetic stirring. The resulting mixture was stirred in air for 2 h. Then, the formed yellow precipitate was collected by centrifugation, washed alternately with distilled water and pure ethanol, and dried at 80 °C for 3 h to obtain BiIO;

[0025] (3) Dissolve 0.05g of p-nitrophenol and 17.3ul of pyrrole into 5.0ml of methanol:distilled water (1:1, V / V) mixture, and stir the mixture for 30 min in the dark to prepare the pre-self-assembly solution ;

[0026] (4) Suspend 0.5 g BiIO in 100 ml of HCl solution (pH=2), deoxidize and sonicate for 30 min to obtain a uniformly dispersed solution. Assembly solution was added to this solution. Then, 2 ml containing 0.27 g FeCl 3 solution (pH=2) was added dropwise to the...

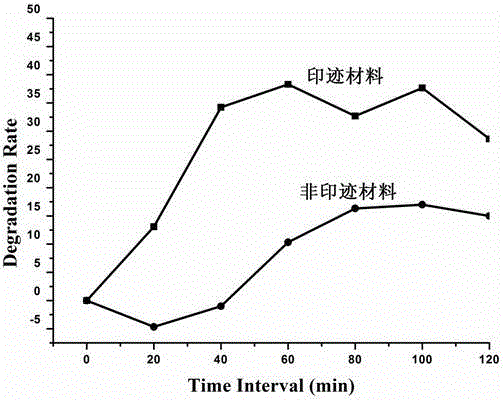

Embodiment 3

[0030] (1) 1.51g Bi(NO 3 ) 3 ·5H2 O, 0.4g PVP-K30 and 5ml HNO 3 (1.0 M) was added to 50 ml distilled water to form solution A; 0.5 g KI, 0.40 g PVP-K30 were added to 60 ml distilled water to form solution B. Solution B was then added dropwise to solution A under magnetic stirring. The resulting mixture was stirred in air for 2 h. Then, the formed yellow precipitate was collected by centrifugation, washed alternately with distilled water and pure ethanol, and dried at 80 °C for 3 h to obtain BiIO;

[0031] (3) Dissolve 0.05g of p-nitrophenol and 17.3 ul of pyrrole into 5.0 ml of methanol: distilled water (1:1, V / V) mixture, and stir the mixture for 30 min in the dark to prepare a pre-self-assembly solution ;

[0032] (4) Suspend 0.5g BiIO in 100 ml of HCl solution (pH=2), deoxidize and sonicate for 30 min to obtain a uniformly dispersed solution. Assembly solution was added to this solution. Then, 2 ml containing 0.27 g FeCl 3 solution (pH=2) was added dropwise to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com