A clamping tool and a method for capillary pipeline welding using the clamping tool

A capillary and clamping technology, applied in welding equipment, welding accessories, applications, etc., can solve the problems of difficult welding operation, poor welding quality, and difficult control of welding seam parameters, so as to achieve good welding operation environment and internal quality of welding seam High, improve the effect of monitoring ability and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

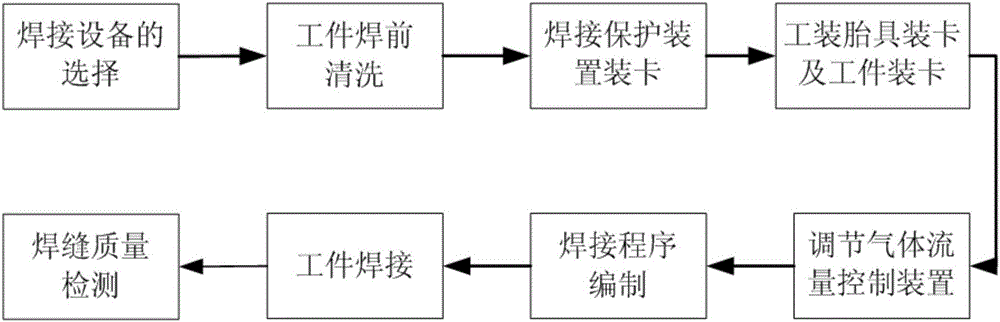

Method used

Image

Examples

Embodiment 1

[0088] The welding material is stainless steel capillary (capillary outer diameter Φ1.7 / inner diameter Φ0.7), the diameter of the selected tungsten electrode is Φ1.6, the cone length is 5mm, the welding speed is set at 7r / min; the gas flow rate of the welding torch is 15L / min, The welding arc voltage is adjusted to 9V; the welding current is divided into 8 sections, the average welding current of each section is about 8A, the base value current is set to 30% of the peak current, the gas flow in the inner hole is controlled to 1.5L / min, and the gas protection is used hood, the auxiliary gas flow rate is 20L / min, the number of welding turns is 2.5 turns, and the welding time of each section is approximately equal.

[0089] Test results: After welding, the weld depth consistency is good, the fusion width is greater than 0.8, and the weld quality conforms to the second-grade weld standard of QJ2865-1997.

Embodiment 2

[0091] The welding material is stainless steel capillary (capillary outer diameter Φ1.5 / inner diameter Φ0.5), tungsten pole with a diameter of Φ1.6, cone length of 5mm, welding speed set at 5r / min; gas flow rate of welding torch is 10L / min, The welding arc voltage is adjusted to 8V; the welding current is divided into 5 sections, the average welding current of each section is about 7A, the base value current is set to 25% of the peak current, the gas flow in the inner hole is controlled to 1.0L / min, and the gas protection is used hood, the auxiliary gas flow rate is 10L / min, the number of welding turns is about 1.5 turns, and the welding time of each section is approximately equal.

[0092] Test results: After welding, the weld depth consistency is good, the fusion width is greater than 0.8, and the weld quality conforms to the second-grade weld standard of QJ2865-1997.

Embodiment 3

[0094] The welding material is stainless steel capillary (capillary outer diameter Φ1.2 / inner diameter Φ0.4), the diameter is Φ1mm tungsten electrode, the cone length is 4mm, the welding speed is set at 3r / min; the gas flow rate of the welding torch is 10L / min, and the welding arc The voltage is adjusted to 7V; the welding current is divided into 3 sections, the average welding current of each section is 4A, the base value current is set to 20% of the peak current, the auxiliary gas flow rate is 5L / min, and the number of welding turns is about 1 Circle, each section of welding time is approximately equal.

[0095] Test results: After welding, the weld depth consistency is good, the fusion width is greater than 0.8, and the weld quality conforms to the second-grade weld standard of QJ2865-1997.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com