Preparation method and applications of graphene aerogel

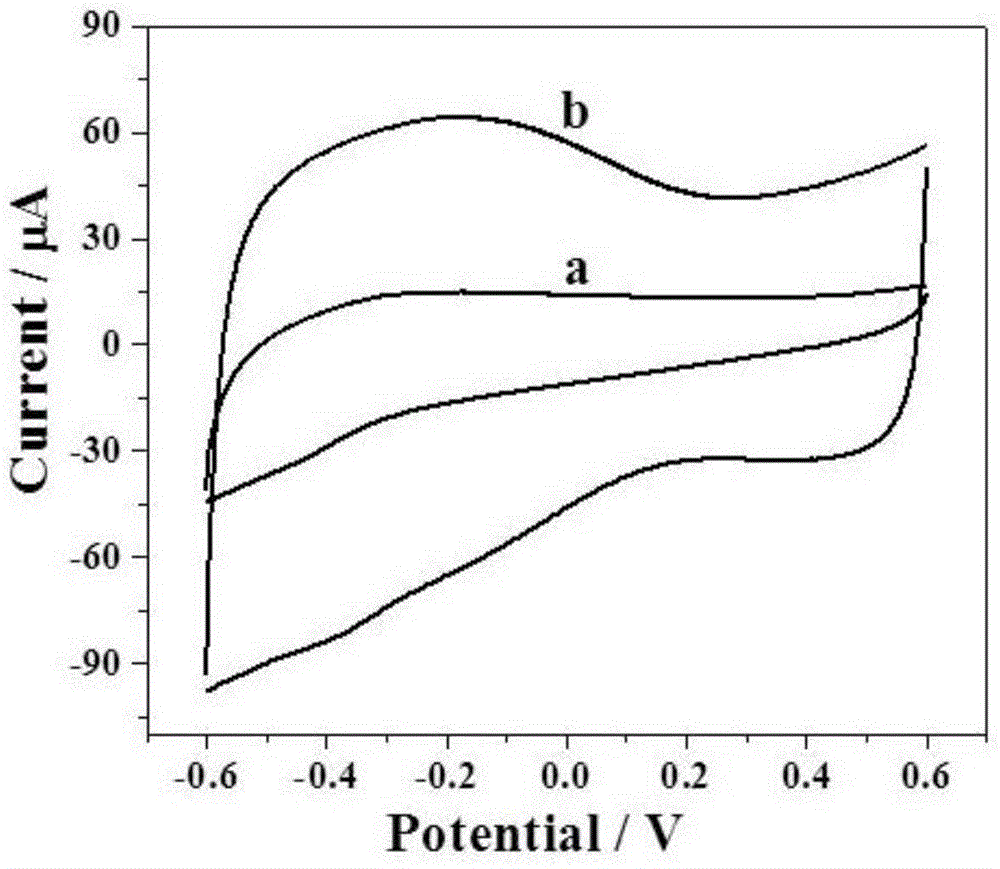

A graphene aerogel and graphene technology, which is applied in the field of graphene materials, can solve the problems of high detection limit of micro-electrodes, inability to detect nitrate ions, etc., and achieve the effect of low detection limit, sensitive detection, and widening research fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

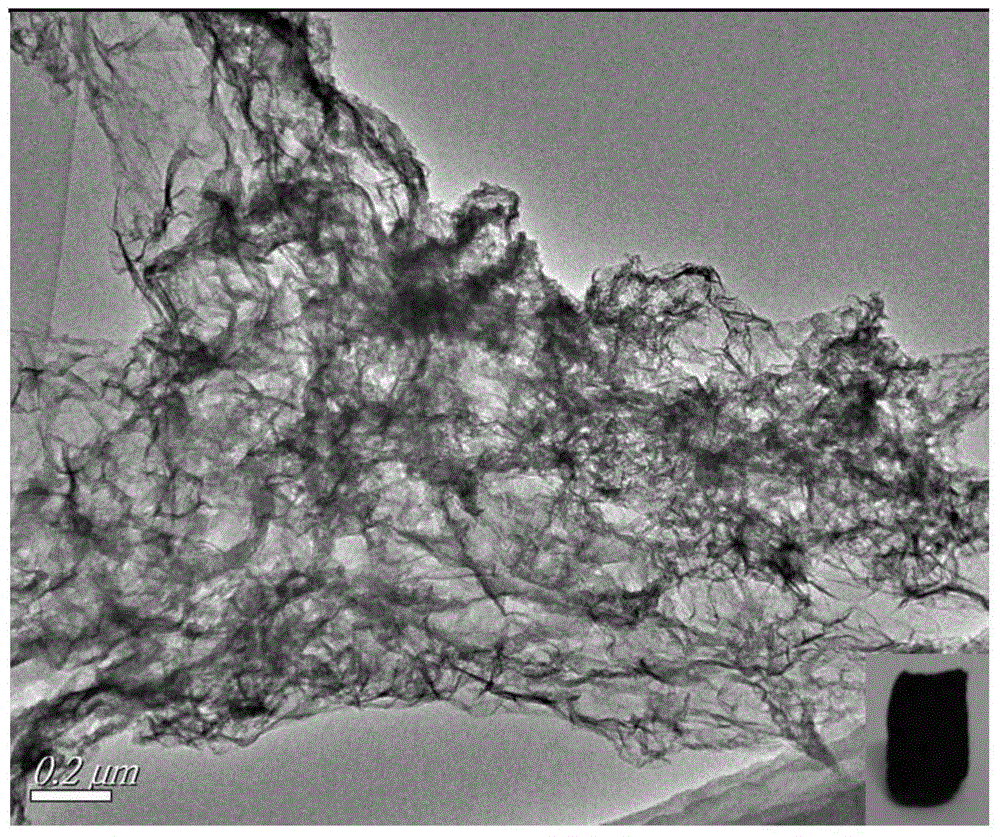

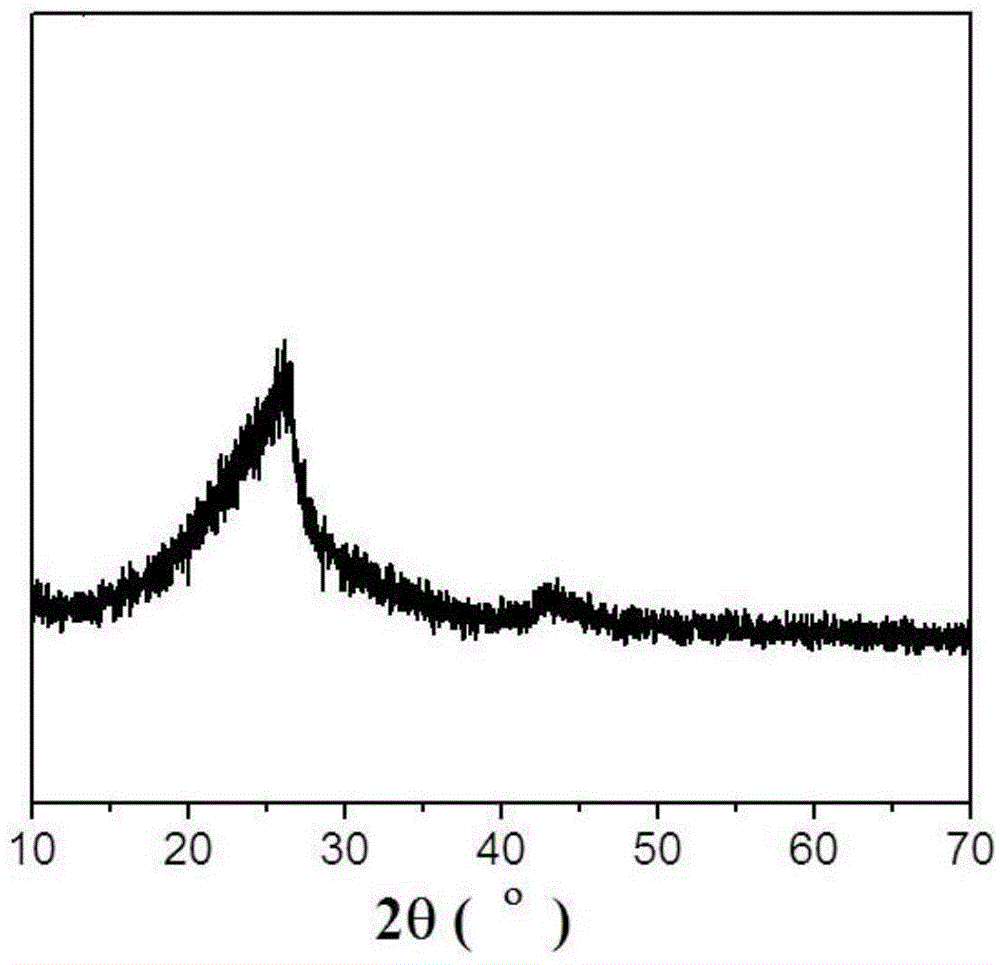

[0035] Weigh 50mg of solid graphene oxide and place it in 10mL double-distilled water, ultrasonicate for 30min to make a graphene oxide aqueous solution, transfer the aqueous solution into a 15mL cylindrical glass bottle, then transfer the glass bottle to a 25mL polytetrafluorohydrothermal solution In the kettle, keep the reaction at 160°C for 24h, and wait for the reaction kettle to cool down to room temperature to obtain a cylindrical product; pre-freeze the cylindrical product at -4°C; put the pre-frozen material into a freeze dryer , freeze-dried at -80°C for 12 h to obtain graphene airgel GAs.

[0036]Weigh 1 mg of GAs prepared in this example and ultrasonically disperse it in 0.5 mL of twice distilled water to form a 2.0 mg / mL suspension. 6 μL of graphene airgel suspension was drop-coated on the surface of the working electrode of the screen-printed electrode, and dried at room temperature to obtain a GAS-modified screen-printed electrode (referred to as SPE / GAS); 100 μL...

Embodiment 2

[0038] Weigh 20 mg of solid graphene oxide and place it in 20 mL of twice-distilled water, ultrasonicate for 30 minutes to make a graphene oxide aqueous solution, transfer the aqueous solution into a 25 mL polytetrafluorohydrothermal kettle A, and then place the polytetrafluorohydrothermal kettle A is transferred to a 100mL polytetrafluorohydrothermal kettle B, and the reaction is maintained at 120°C for 12h. After the reaction kettle is lowered to room temperature, a cylindrical product is obtained; the cylindrical product is pre-frozen at -2°C; The pre-frozen material was placed in a freeze dryer and freeze-dried at -40°C for 24 hours to obtain graphene airgel GAs.

[0039] Weigh 1 mg of GAs prepared in this example and ultrasonically disperse in 1 mL of twice distilled water to form a 1.0 mg / mL suspension. Take 10 μL of graphene airgel suspension drop-coated on the surface of the working electrode of the screen-printed electrode, and dry it at room temperature to obtain a G...

Embodiment 3

[0041] Weigh 50mg of solid graphene oxide and place it in 10mL double-distilled water, ultrasonicate for 30min to make a graphene oxide aqueous solution, transfer the aqueous solution into a 15mL cylindrical glass bottle, then transfer the glass bottle to a 25mL polytetrafluorohydrothermal solution In the kettle, the reaction was kept at 160°C for 24h, and the reaction kettle was lowered to room temperature to obtain a cylindrical product; the cylindrical product was placed in absolute ethanol for solvent exchange 5 times, and the product after the solvent exchange was transferred to CO 2 Drying in supercritical drying equipment, CO 2 Supercritical drying equipment parameters are: CO 2 Flow 1.2m 3 / h, the temperature is 40°C, the pressure is 14MPa, the time is 12h, and the graphene airgel GAs is obtained after drying.

[0042] The GAs prepared in this example were used for the all-solid-state nitrate ion selective electrode to detect nitrate ions, and the operation steps we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com