Modified cement slurry for concrete repair and preparation method thereof

A technology for modifying water and concrete, which is applied in the field of modified cement slurry for concrete repair and its preparation. It can solve the problems of unbearable, high cost of resin mortar or concrete, and achieve good durability, reduced bulk density, and increased folding pressure. than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing the above-mentioned modified cement slurry for concrete repair, including the following steps:

[0027] a) Select a predetermined amount of cement, aggregate and fly ash to mix;

[0028] b) Add a predetermined amount of styrene-butadiene emulsion, defoamer and early strength agent to tap water, and then mix with the mixed material water in step a); the predetermined weight percentage of each component is controlled as follows: cement 30~70 %; aggregate 12.5%~52.5%; fly ash 12~15%; styrene-butadiene emulsion 5%~15%; early strength agent 0.25~5.5%; defoamer 0.25~1%;

[0029] c) Control the fluidity of the mortar within the range of 140±5mm, and then measure the fluidity and bulk density of the freshly mixed mortar respectively, and confirm that the fluidity and bulk density of the freshly mixed mortar are roughly the same as the concrete to be repaired, and then the pouring is carried out. repair.

[0030] In the prepara...

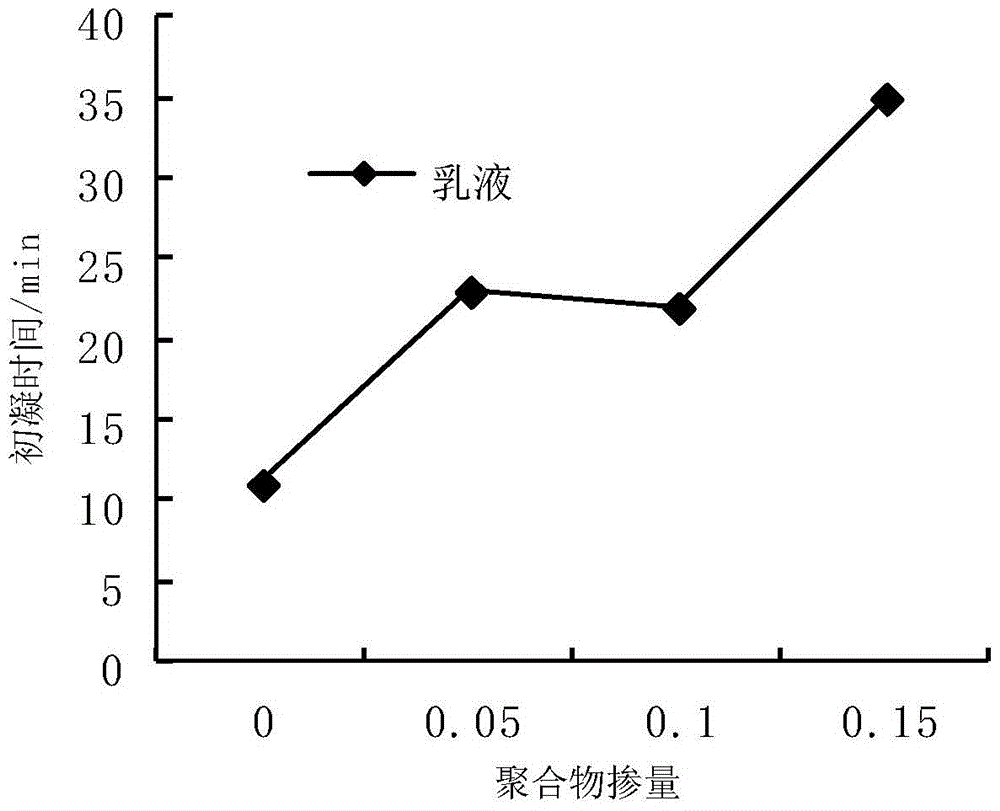

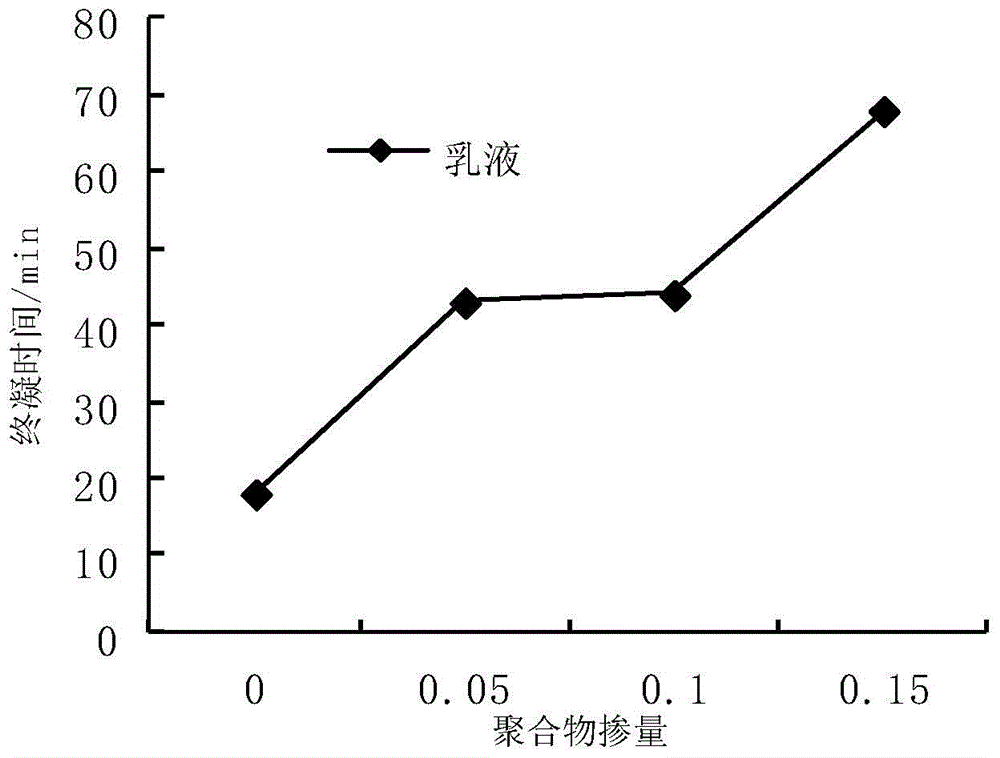

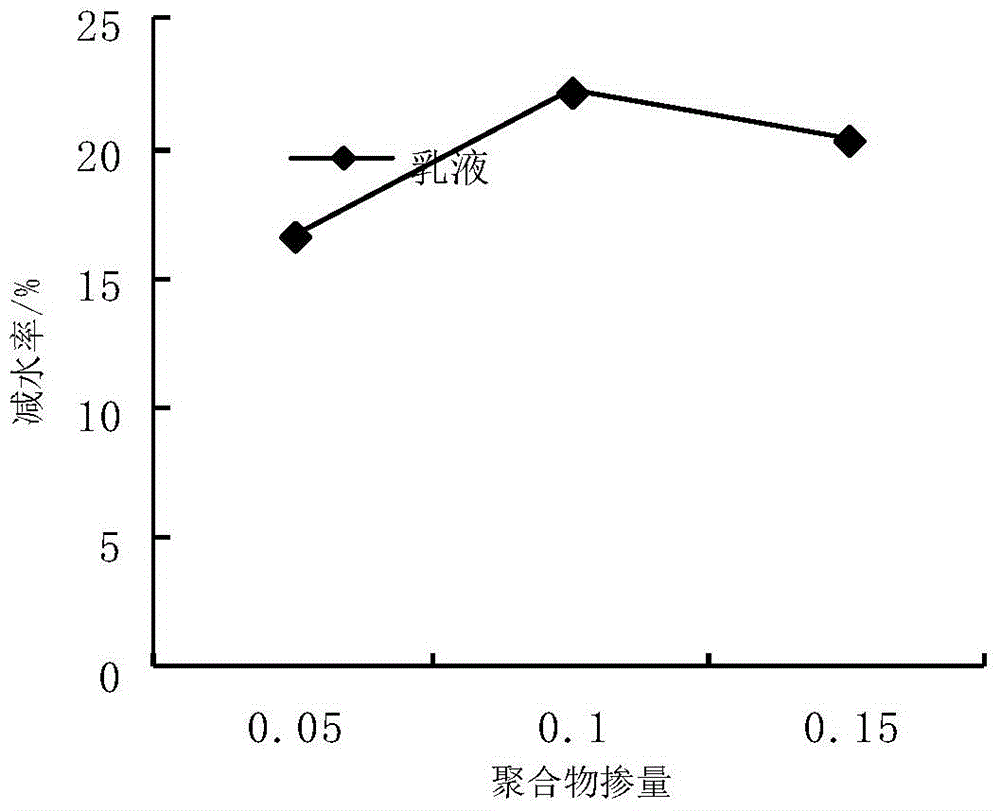

experiment example

[0034] 1. Raw materials

[0035] Cement: Super early strength sulfoaluminate cement was used in the test.

[0036] Aggregate: Standard sand used for mortar test.

[0037] Fly ash: Yahekou Class I fly ash, 45 micron sieve rate is 6.56%, water demand rate is 92%, density is 2.32g / cm 3 .

[0038] Polymer: The polymer adopts styrene-butadiene emulsion SD623 from Shanghai Gaoqiao BASF Dispersion Co., Ltd., with a solid content of 50%-52%, a PH value of 7.8-10, and a density of 1.01g / cm 3 , The average particle size is 150nm, and the glass transition temperature is 13°C.

[0039] The defoamer is a mixture of liquid liquid hydrogen compound, polyethylene glycol and amorphous silica, and the weight ratio of the liquid liquid hydrogen compound, polyethylene glycol and amorphous silica is 0.5:2.5:2.5, The appearance density is about 340g / L.

[0040] Tap water is used for the mixing water.

[0041] 2. Sample preparation and testing

[0042] The preparation method refers to the cement paste test meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com