Composition for preparing non-yellowing soft polyurethane foam, non-yellowing soft polyurethane foam and preparation method of non-yellowing soft polyurethane foam

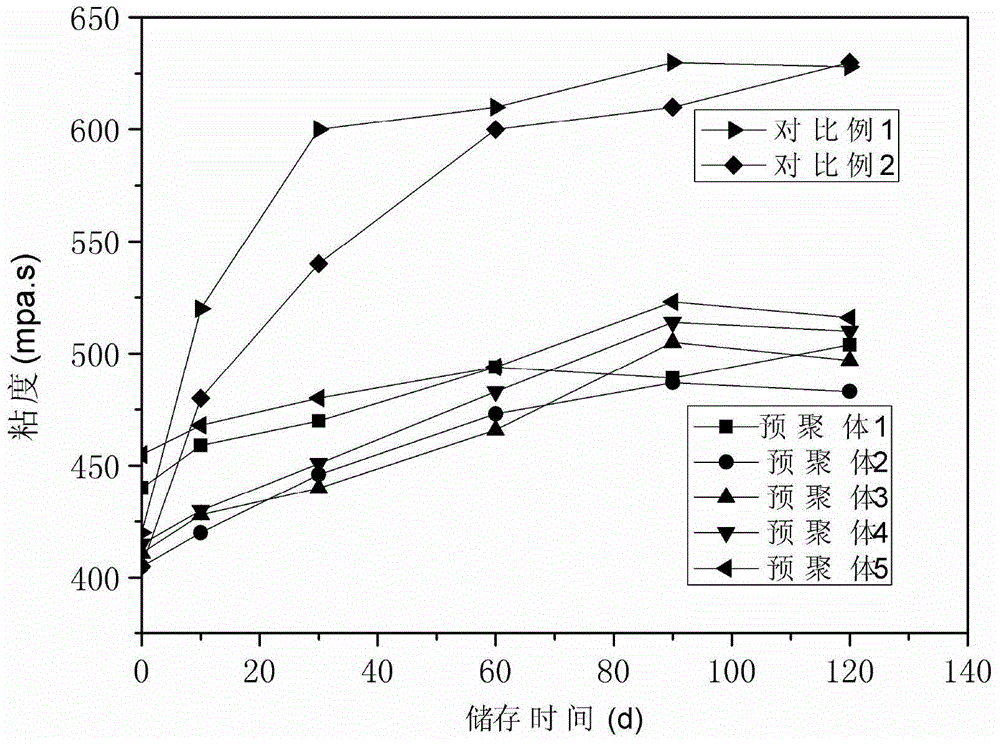

A technology of soft polyurethane and polyurethane prepolymer, which is applied in the field of preparation of non-yellowing soft polyurethane foam composition, which can solve problems such as insufficient reactivity and difficulty in determining the curing time, achieve excellent anti-light performance, and improve environmental stability Sex, the effect of avoiding foam collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

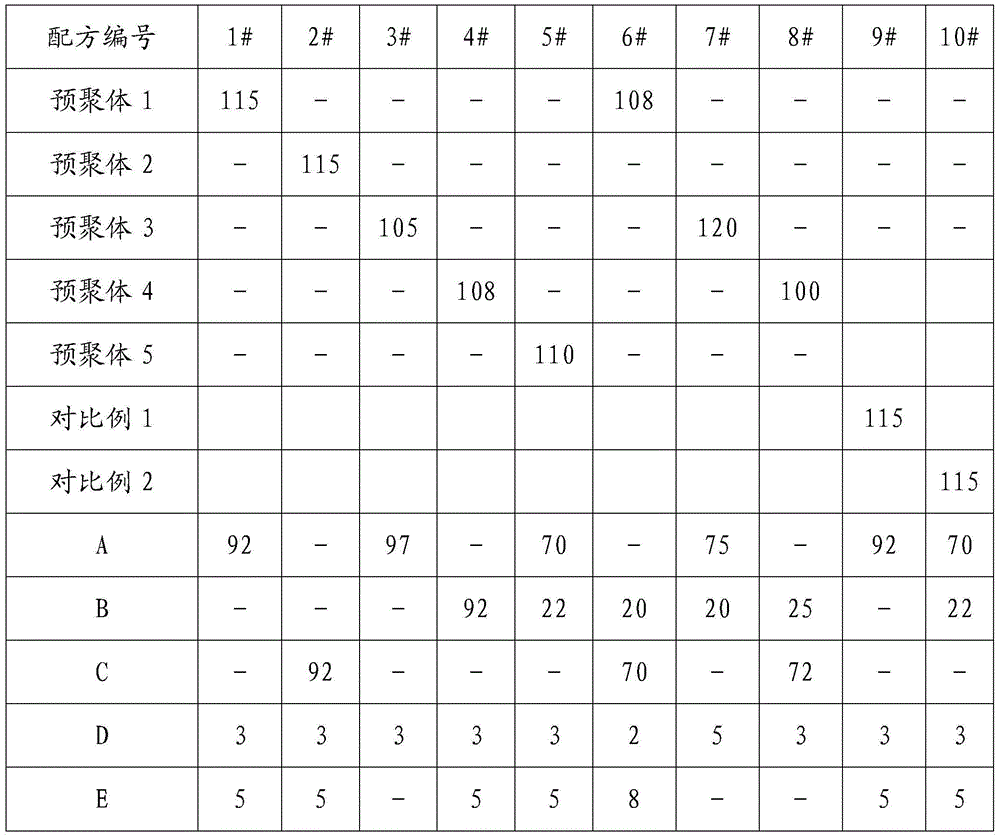

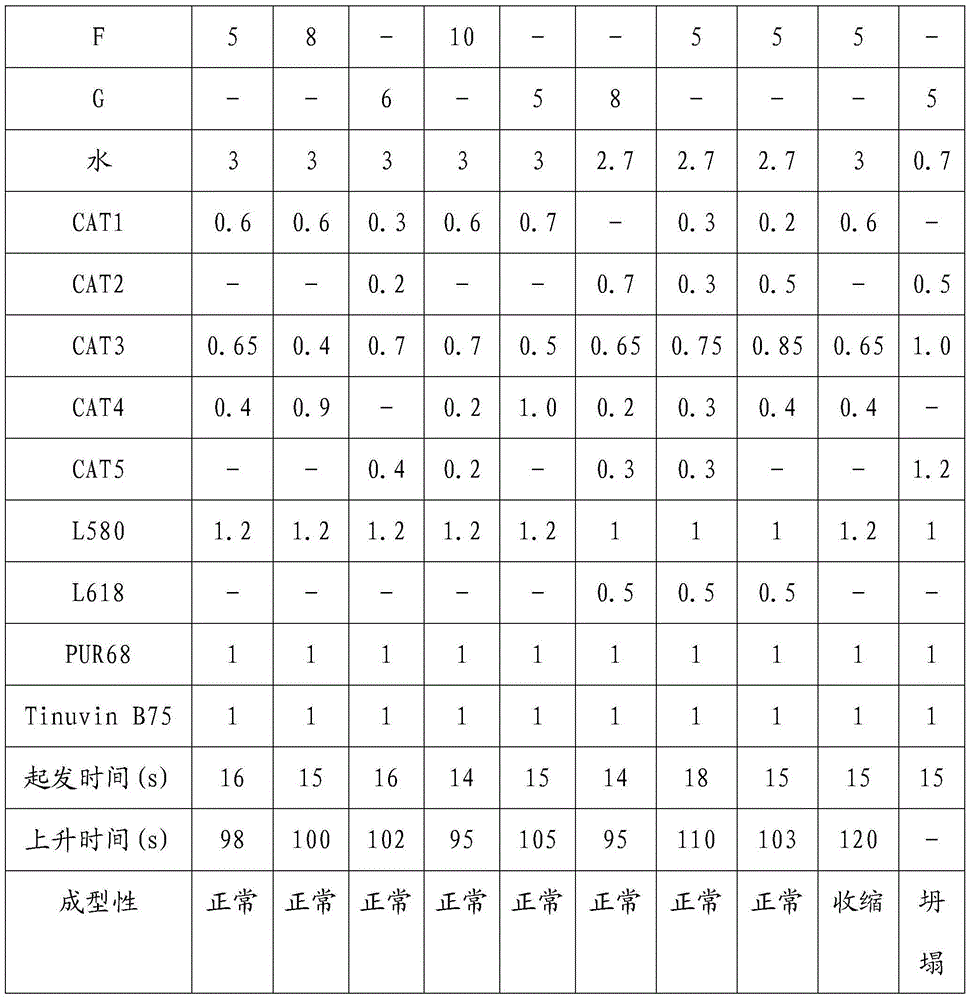

[0044] The following embodiments will further illustrate the method provided by the present invention, but the present invention is not limited to the listed embodiments, and should also include any other known changes within the scope of the claims of the present invention.

[0045] Preparation of Aliphatic Polyurethane Prepolymer

[0046] Polyol 1: GEP-560 (polyether polyol, Shanghai Gaoqiao Petrochemical, nominal functionality 3, OH value=56mgKOH / g, EO content about 10.0%)

[0047] Polyol 2: 330N (polyether polyol, Tianjin Sanpec, nominal functionality 3, OH value=36mgKOH / g, EO content about 16.0%, primary hydroxyl content about 75.0%)

[0048] Polyol 3: DL-2000 (polyether polyol, Dongda Bluestar, nominal functionality 2, OH value=56mgKOH / g, nominal molecular mass 2000)

[0049] Polyol 4: DL-1000 (polyether polyol, Dongda Bluestar, nominal functionality 2, OH value=112mgKOH / g, nominal molecular mass 1000)

[0050] Polyol 5: Voranol220-260 (polyether polyol, Dow company, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oh value | aaaaa | aaaaa |

| Functionality | aaaaa | aaaaa |

| Functionality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com