Polyethersulfone ultrafine powder, its use, coatings containing polyethersulfone ultrafine powder and their preparation method

A technology of ultra-fine powder and polyethersulfone, which is applied in the field of materials and coatings, can solve the problems of reducing glass quality and achieve the effect of improving surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] According to the method described above, the performance of the polyethersulfone ultrafine powder of the present invention is tested. in:

[0102] (1) In the test of mixing degree with water, add 100g of polyethersulfone micropowder particles to 100g of purified water containing 1wt% wetting agent W22 (Huanqi Chemical (Guangdong) Co., Ltd.). The obtained mixed solution was dispersed at a low speed of 100 rpm for 20 minutes, then left to settle, and the layering was observed. The measured degree of mixing of the polyethersulfone fine powder particles with water is shown in Table 1 below.

[0103] The inventors found through research that the polyethersulfone ultrafine powder particles within the particle size range of the present invention have better affinity for water.

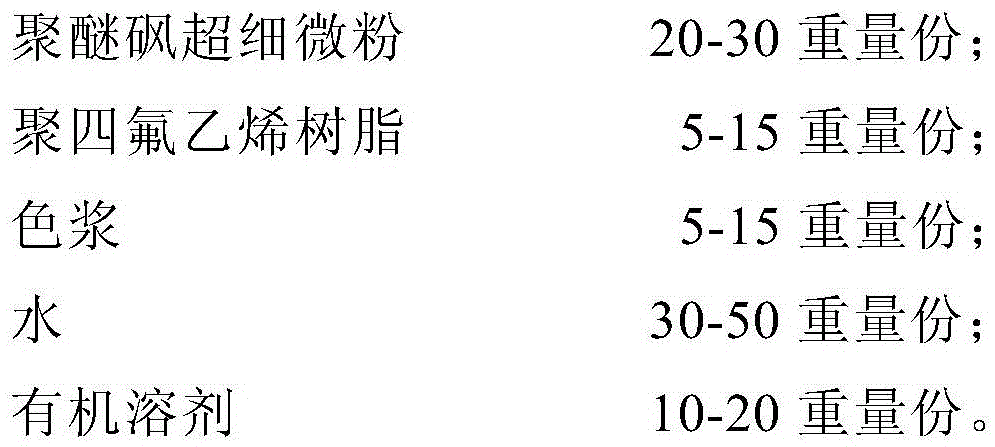

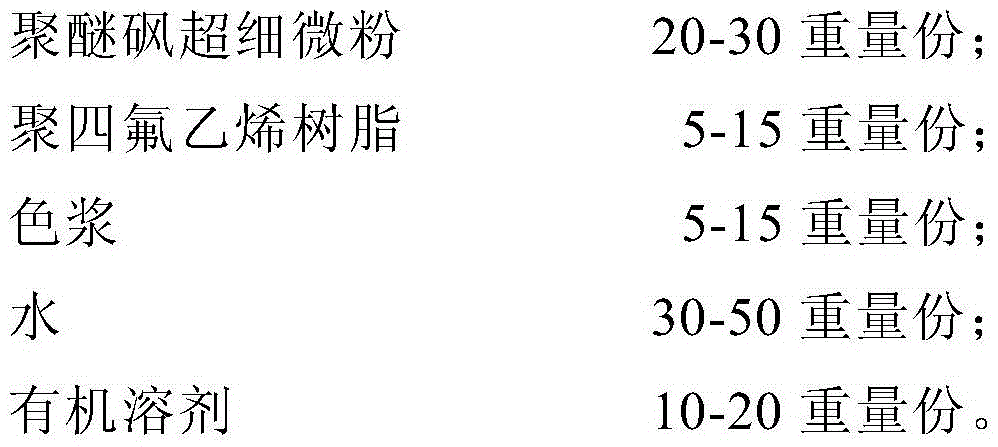

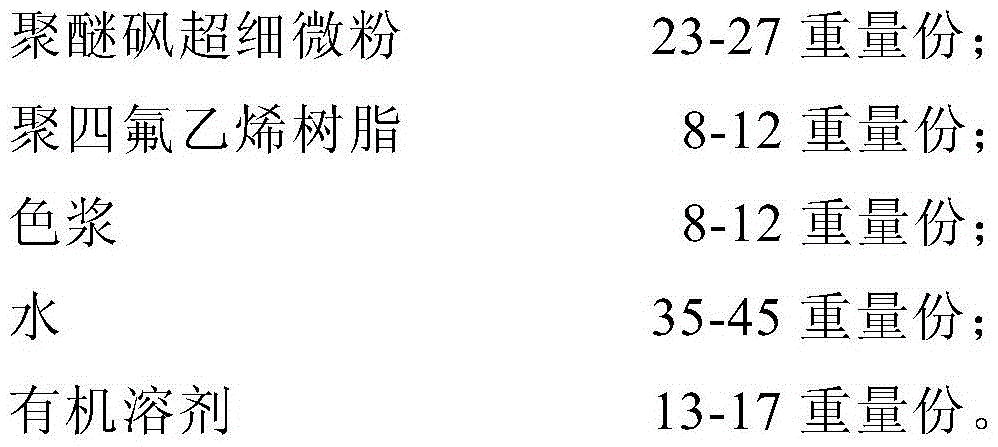

[0104] (2) In the drying and film-forming ability test after the paint is made, polyethersulfone micropowders with different particle sizes are made into paint according to the following formula:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com