Direct sending and loading process of T91 steel continuous casting billet

A continuous casting and direct technology, applied in the field of metal material processing, can solve the problems of increased difficulty in continuous casting process control, large temperature range of hot charging, and increased solid solution time of alloys, so as to avoid corner crack defects of billets and shorten the In furnace time, the effect of avoiding corner crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

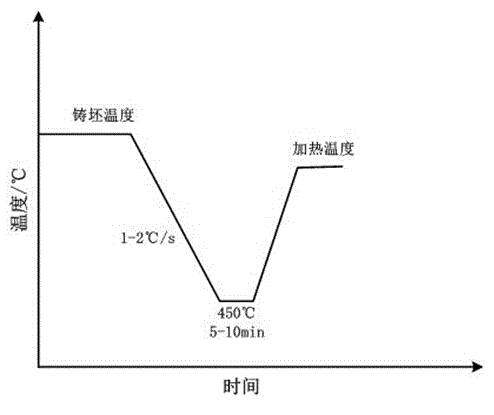

Embodiment 1

[0014] A 320mm×480mm continuous casting billet of T91 steel in a steel plant is cooled at 1.5°C / s during the conveying process. When the surface temperature reaches the target temperature of 440°C, it is reheated for 8 minutes, then sent to the heating furnace for high temperature heating, and rolled to wear T91 steel pipe billets with a diameter of Ф120 are used, and the quality of the pipe billets is excellent. After rapid cooling, the high-temperature structure and morphology of T91 steel continuous casting billet at 440 ° C and when it is heated out of the furnace are retained. After metallographic and performance analysis, the billet structure is uniform and the hardness is small. The hardness is 347HV and 370HV respectively, which has good The processing plasticity shows that the direct hot charging process of the T91 steel continuous casting billet of the present invention can well satisfy the production.

Embodiment 2

[0016] A 320mm×480mm continuous casting billet of T91 steel in a steel plant is cooled at 1°C / s during the conveying process. When the surface temperature reaches the target temperature of 450°C, it is reheated for 5 minutes, then sent to the heating furnace for high temperature heating, and rolled to wear T91 steel billet with Ф80 is used. After rapid cooling, the high-temperature structure and morphology of the T91 steel continuous casting billet at 450 ° C and when it was heated out of the furnace were retained. After metallographic and performance analysis, the billet structure was uniform and the hardness was small. The hardness was 344HV and 367HV respectively, due to the original billet The deformation of the corner is large, and the tissue strength and hardness are high here, and it still has good processing plasticity. It shows that the direct hot charging process of the T91 steel continuous casting billet of the present invention can well meet the requirements of pro...

Embodiment 3

[0018] The 320mm×480mm continuous casting billet of T91 steel in a steel plant is cooled at 2°C / s during the conveying process. When the surface temperature reaches the target temperature of 460°C, it is reheated for 5 minutes, then sent to the heating furnace for high temperature heating, and rolled to wear Use Ф60 T91 steel billet. After rapid cooling, the high-temperature structure and morphology of T91 steel continuous casting billet at 460 ° C and when it was heated out of the furnace were retained. After metallographic and performance analysis, the billet structure was uniform and the hardness was small. The hardness was 346HV and 373HV respectively, due to the original billet The corner deformation is very large, and the structure strength and hardness are high here, which can still meet the production of tube blanks without surface crack defects. It shows that the direct hot charging process of the T91 steel continuous casting billet of the present invention can well m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com