Stock taking method and system for stocking yard

A material yard and material tray technology, applied in the field of inventory monitoring equipment, can solve the problems of easily affected communication, complex working process, low adaptability, etc., to avoid debugging difficulties, reduce system errors, and ensure the effect of real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

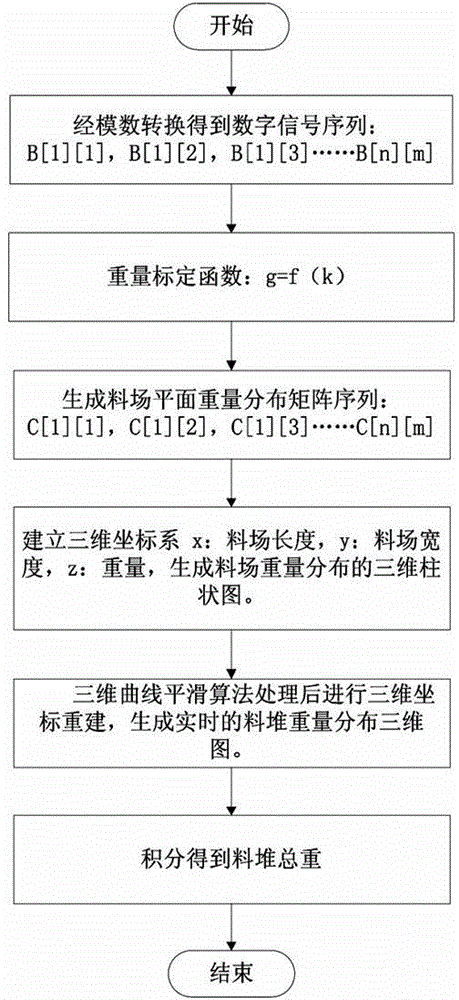

[0027] Such as figure 1 Shown, the disk material method that is used for stock yard of the present invention, its steps are:

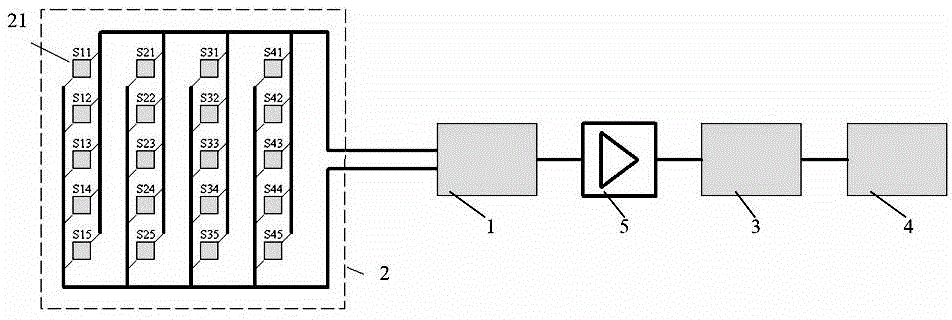

[0028] (1) Evenly distribute pressure sensors S[1][1], S[1][2] S[1][3]...S[n][m] in the stockyard plane, where n is greater than or equal to 1 is an integer, m is an integer greater than or equal to 1, and a pressure distribution network structure is formed by the above-mentioned certain number of pressure sensors.

[0029] In the above-mentioned pressure distribution network structure, pressure sensors are used to measure physical quantities such as pressure, strain and temperature at the distribution points of the stockyard.

[0030] (2) Each pressure sensor monitors the pressure in the corresponding area to form a detection signal;

[0031] (3) Data processing: Calculate the detection signal obtained fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com