Stock yard weight detection method and system

A technology of weight detection and material yard, applied in weighing, weighing equipment and measuring devices of materials with special properties/forms, etc., can solve the problems of complex working process, low precision, low adaptability, etc. structure, reduce system errors, and ensure the effect of real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

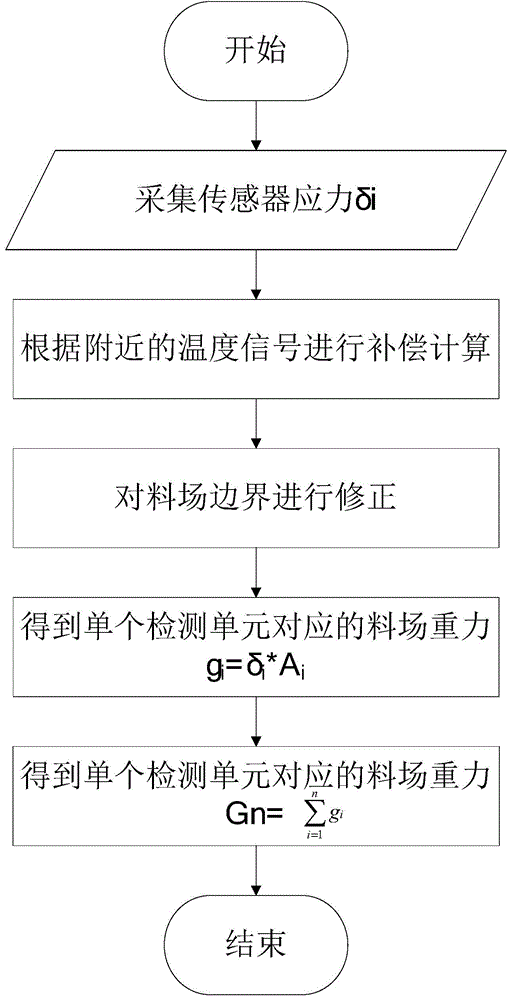

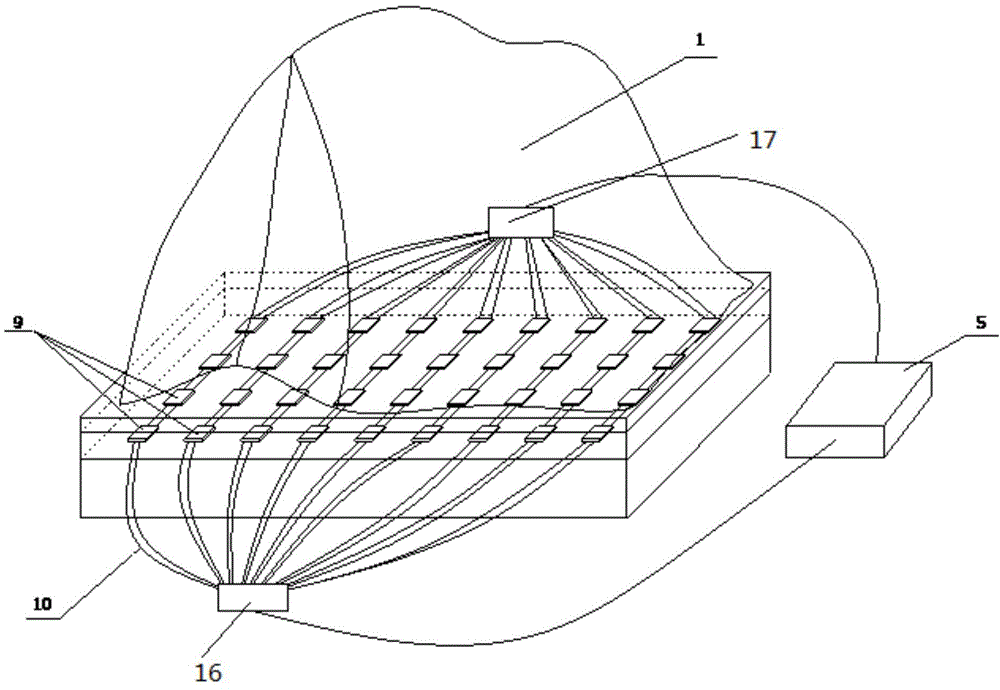

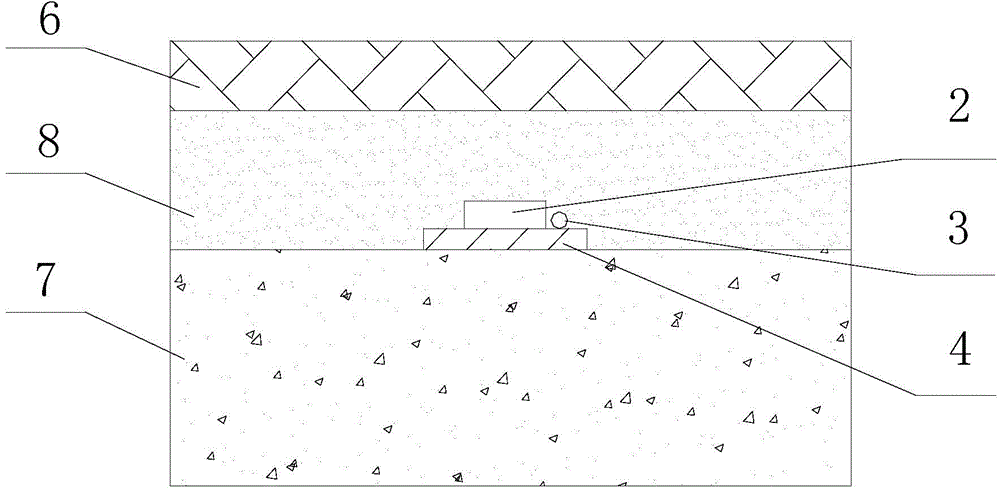

[0031] The stockyard weight detection method of the invention is especially suitable for dynamic real-time monitoring and management of the stockyard. A pressure sensing device is arranged on the foundation 7 at the stockyard. The pressure sensing device is used to detect the pressure on the action area in real time, and convert the pressure into the weight of the material 1 on the stockyard. The present invention can be applied to various stockyards, such as large-scale artificial sand and gravel stockyards, port warehouses, artificial hills, etc., so as to realize real-time weighing of stockyards and hills. The pressure sensing device usually has two types of vibrating wire type and fiber optic sensor, and the fiber optic sensor is used as an example in this example. The fiber optic sensor can choose more than one fiber optic mano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com