Biosensor for detecting okadaic acid and preparation method

A kind of okadaic acid and biosensor technology, applied in the field of analysis and detection, can solve the problems of high cultivation period and cost, unintuitive detection results, unsuitable for rapid detection, etc., and achieve intuitive detection results, short detection cycle and rapid detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

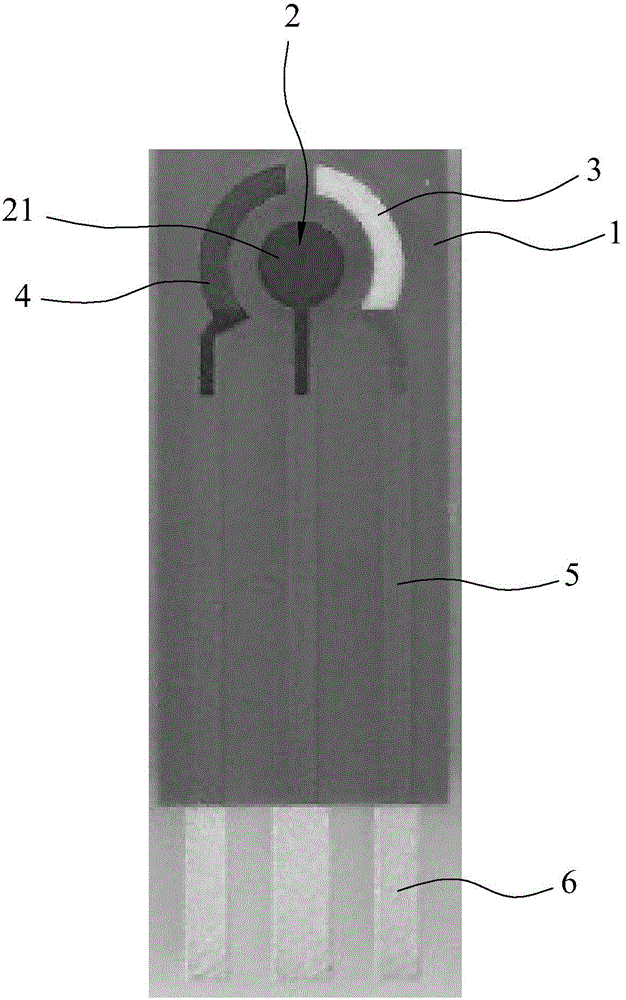

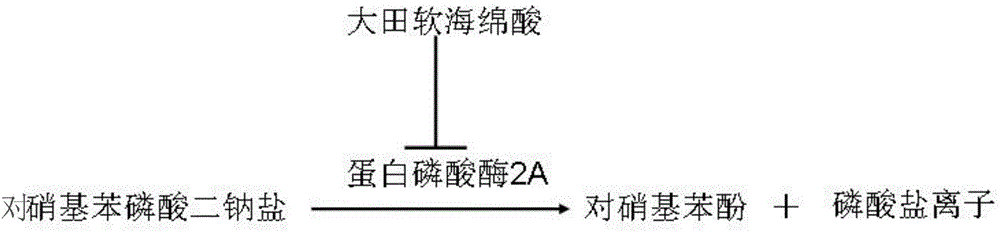

[0028] Clean the PVC film substrate (Sigma-Aldrich, USA) with working electrode, reference electrode and counter electrode on the surface, and dry it for later use. Dissolve PP2A enzyme in pH 8.4 buffer A containing 30mM Tris–HCl, 2mM EDTA and 20mM MgCl2 to make 1 unit / ul enzyme solution, in which 1 unit of PP2A enzyme is cleaved within 1min at 25°C Amount of enzyme required for p-nitrophenyl phosphate disodium salt. In this enzyme solution, add PVA-AWP (polyvinyl alcohol-has (azide-unit pendant) water-soluble photopolymer of azide unit side group, Toyo Gosey Kogyo corporation, Japan), the quality of PP2A enzyme and PVA-AWP The ratio is 2:1 and a fixative solution is formed after homogenization. Then, 3 ul of fixing solution was added dropwise to the surface of the working electrode, and irradiated for 3 h at 4° C. under a fluorescent lamp with a power of 15 W. After the light was finished, it was further dried at 4°C for 24 hours, and then rinsed with double distilled water...

Embodiment 1-2

[0030]Clean the PVC film matrix with working electrode, reference electrode and counter electrode on the surface, and dry it for later use. Dissolve PP2A enzyme in pH 8 buffer A containing 30mM Tris-HCl, 2mM EDTA and 20mM MgCl2 to make 2 units / ul of enzyme solution, of which 1 unit of PP2A enzyme is cleaved within 1min at 25°C The amount of enzyme required for the disodium salt of p-nitrophenyl phosphate is described. Add PVA-AWP to the enzyme solution, the mass ratio of PP2A enzyme to PVA-AWP is 1:1, and form a fixed solution after homogenization. Then 3.5ul of fixative solution was added dropwise to the surface of the working electrode, and irradiated under a fluorescent lamp with a power of 15W for 4h at 5°C. After the light was finished, it was further dried at 3.5°C for 18 hours, and then rinsed with double distilled water to remove excess PP2A enzyme physically adsorbed. Finally, the prepared immobilized PP2A enzyme electrode was stored at 4°C for use.

Embodiment 1-3

[0032] Clean the PVC film matrix with working electrode, reference electrode and counter electrode on the surface, and dry it for later use. Dissolve PP2A enzyme in pH 8.7 buffer A containing 30mM Tris–HCl, 2mM EDTA and 20mM MgCl2 to make 1.5 units / ul enzyme solution, in which 1 unit of PP2A enzyme is cleaved within 1min at 25°C The amount of enzyme required for the disodium salt of p-nitrophenyl phosphate is described. Add PVA-AWP to the enzyme solution, the mass ratio of PP2A enzyme to PVA-AWP is 1.5:1, and form a fixed solution after homogenization. Then 3 ul of fixing solution was added dropwise to the surface of the working electrode, and irradiated under a fluorescent lamp with a power of 12W for 6 hours at 3°C. After the light was finished, it was further dried at 5°C for 12 hours, and rinsed with double distilled water after drying to remove excess PP2A enzyme physically adsorbed, and finally the prepared immobilized PP2A enzyme electrode was stored at 4°C for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com