Manufacturing method of semiconductor device and manufacturing method of triple mode integrate-insulated gate bipolar transistor (TI-IGBT)

A manufacturing method and semiconductor technology, which is applied in the manufacture of TI-IGBTs and semiconductor devices, can solve problems such as the rate of warping and fragmentation, avoid processing, reduce the probability of warping and fragmentation, and increase the yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

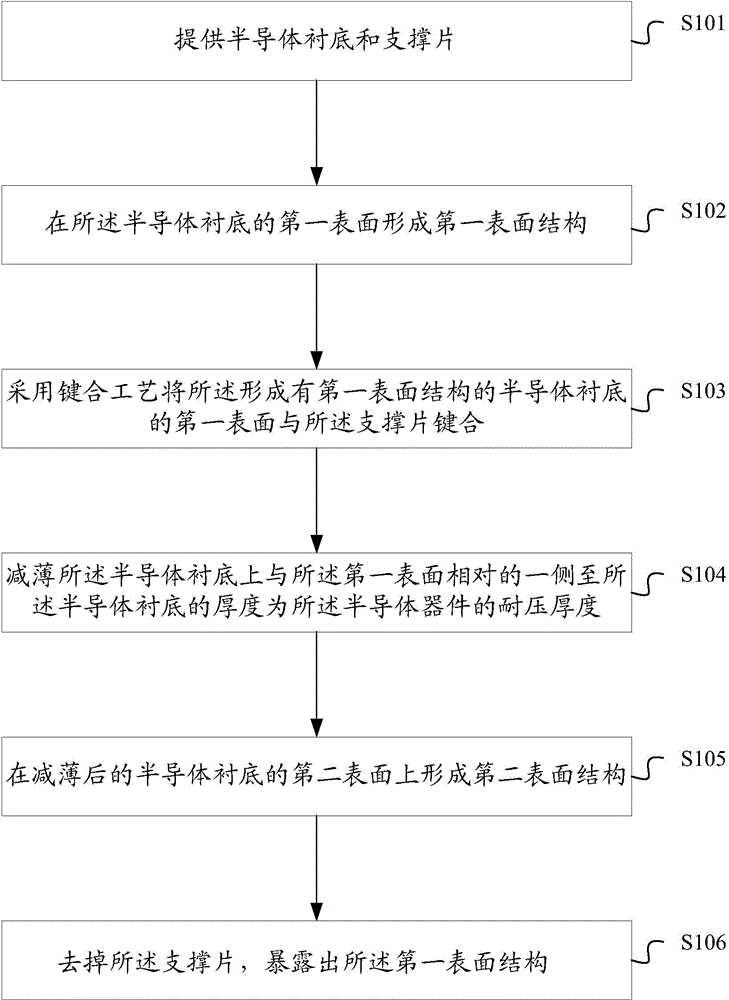

[0041] As mentioned in the background art section, in the prior art, during the process of manufacturing semiconductor devices, the semiconductor substrate is prone to problems of warpage and high fragmentation rate.

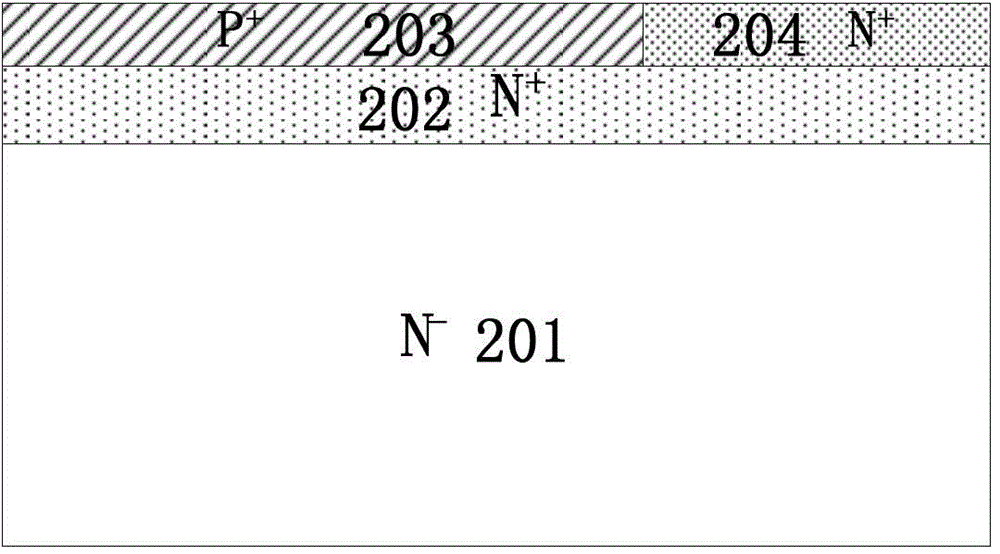

[0042] The inventor found that the reason for the above phenomenon is that the semiconductor device has a withstand voltage thickness, usually its thickness (less than 100 μm) is relatively thin, and in order to reduce the difficulty of the process, the functional area with complex process is usually fabricated on a thicker semiconductor substrate , and then thinning the semiconductor substrate to the withstand voltage thickness required by the semiconductor device, and then manufacturing a relatively simple functional region. However, since the thickness of the thinned semiconductor substrate is very thin, the problem of warping or fragmentation of the semiconductor substrate is prone to occur during the multi-process process.

[0043] Based on this, the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com