Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, which can be used in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as poor adhesion, and achieve the effect of improving the height of the potential barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0051] A-1. Configuration of semiconductor device

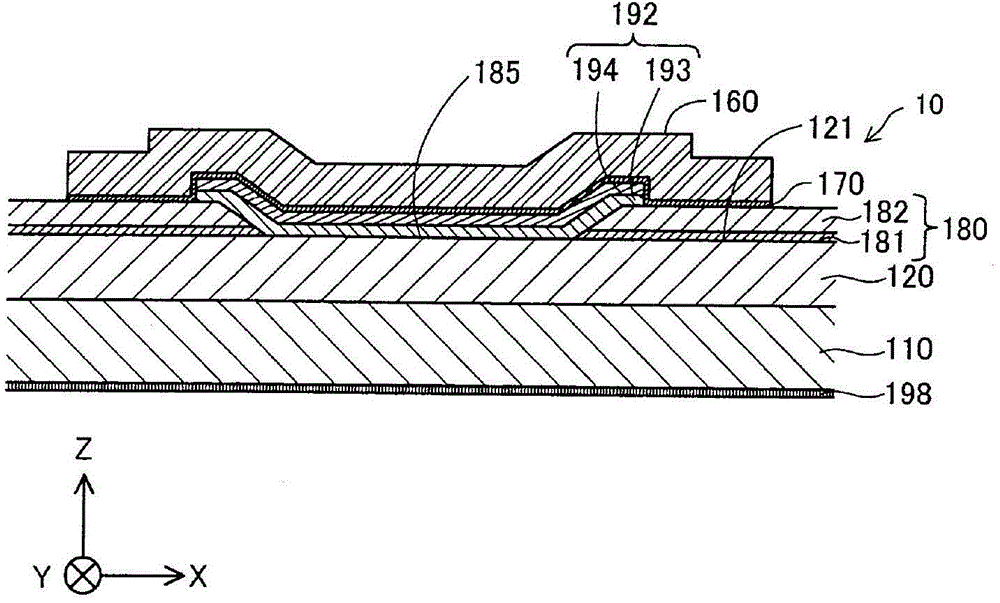

[0052] figure 1 It is a cross-sectional view schematically showing the configuration of the semiconductor device 10 in the first embodiment. figure 1 The diagram in the center has XYZ axes perpendicular to each other.

[0053] figure 1 The XYZ axis, the X axis is from figure 1 The left side of the paper faces the right side of the paper, the +X axis direction is toward the right side of the paper, and the -X axis direction is toward the left side of the paper. figure 1 The XYZ axis, the Y axis is from figure 1 The front of the paper faces the axis of the back of the paper, the direction of the +Y axis is the direction of the back of the paper, and the direction of the -Y axis is the direction of the front of the paper. figure 1 The XYZ axis, the Z axis is from figure 1 The lower side of the paper faces the upper side of the paper, the +Z axis direction is toward the upper side of the paper, and the -Z axis direc...

no. 2 Embodiment approach

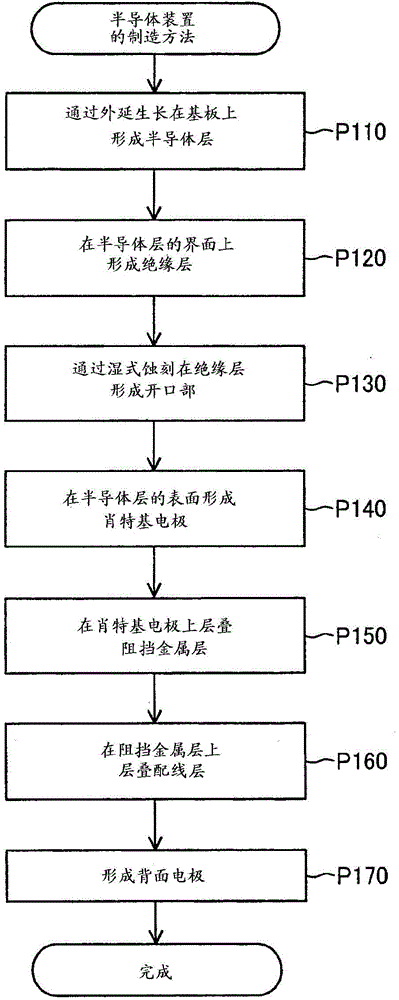

[0093] B-1. Manufacturing method of semiconductor device

[0094] Figure 9 It is a process diagram showing another manufacturing method of the semiconductor device 10 . In the present embodiment, as a manufacturing method, after forming the Schottky electrode 192 in the manufacturing method of the first embodiment (step P140 ), heat treatment is performed in step P145 . By heat treatment after forming the Schottky electrode 192, the nickel layer 193 is sequentially divided from the semiconductor layer 120 side into (i) a layer with less than 0.1% palladium and a film thickness of 50 nm or more, and (ii) a layer with 0.1% or more palladium. . Here, the layer with less than 0.1% of palladium corresponds to the "third layer" in the means for solving the problems, and the layer with 0.1% or more of palladium corresponds to the "fourth layer" in the means for solving the problems.

[0095] B-2. Evaluation of barrier height between semiconductor layer and Schottky electrode befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com