GaN Schottky diode and fabrication method thereof

A gallium nitride Schottky technology and a manufacturing method are applied in the field of gallium nitride Schottky diode structure and its manufacturing, and can solve the problem that the Schottky barrier height cannot be effectively improved, the electron concentration is limited, and the breakdown voltage is increased. problem, to achieve the effect of reducing leakage current, increasing potential barrier height, and increasing breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

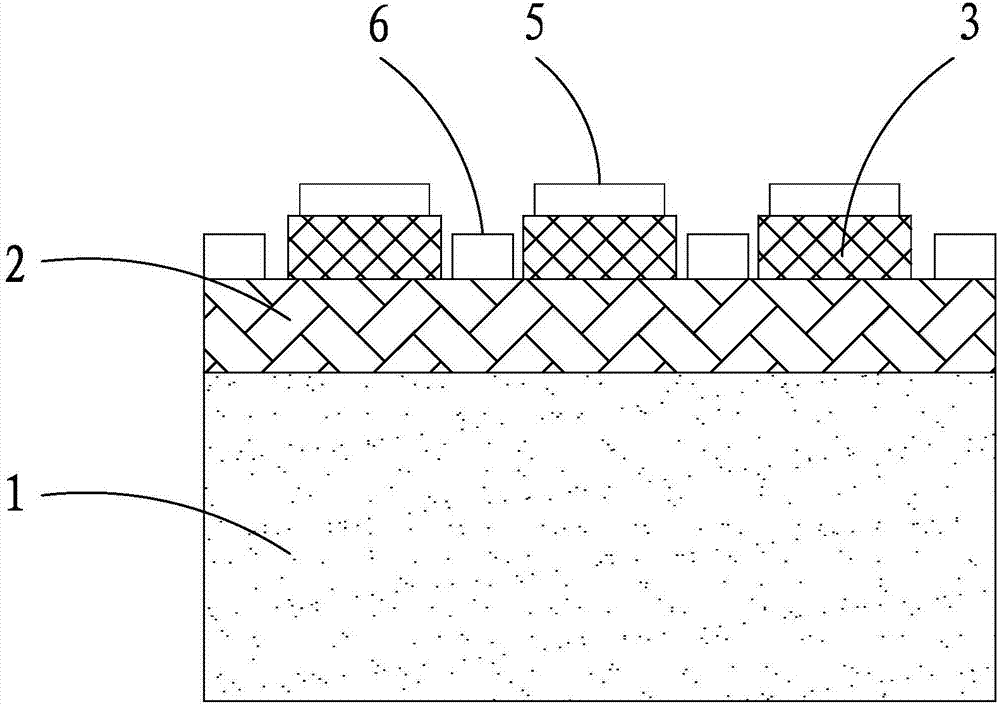

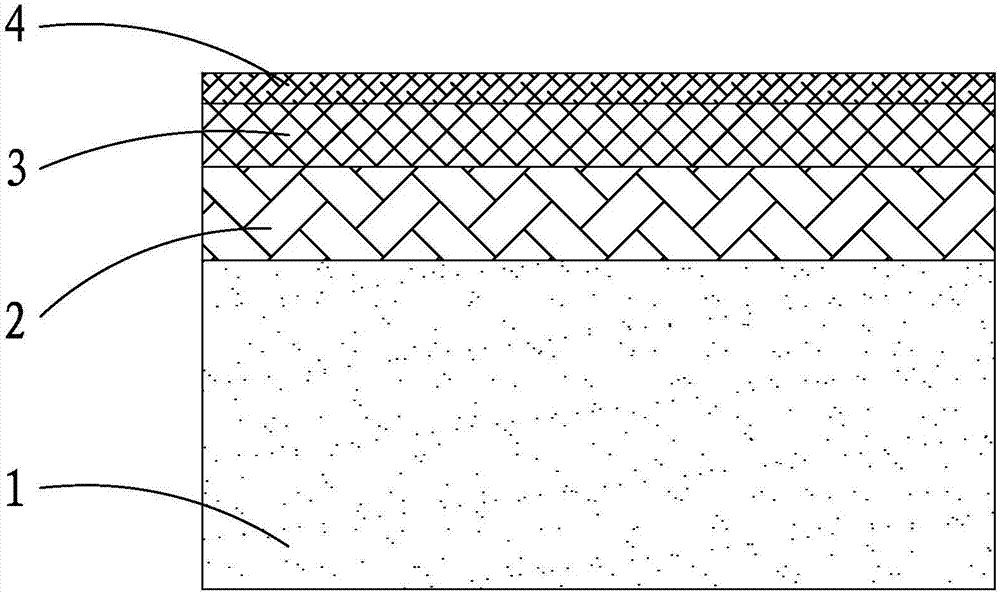

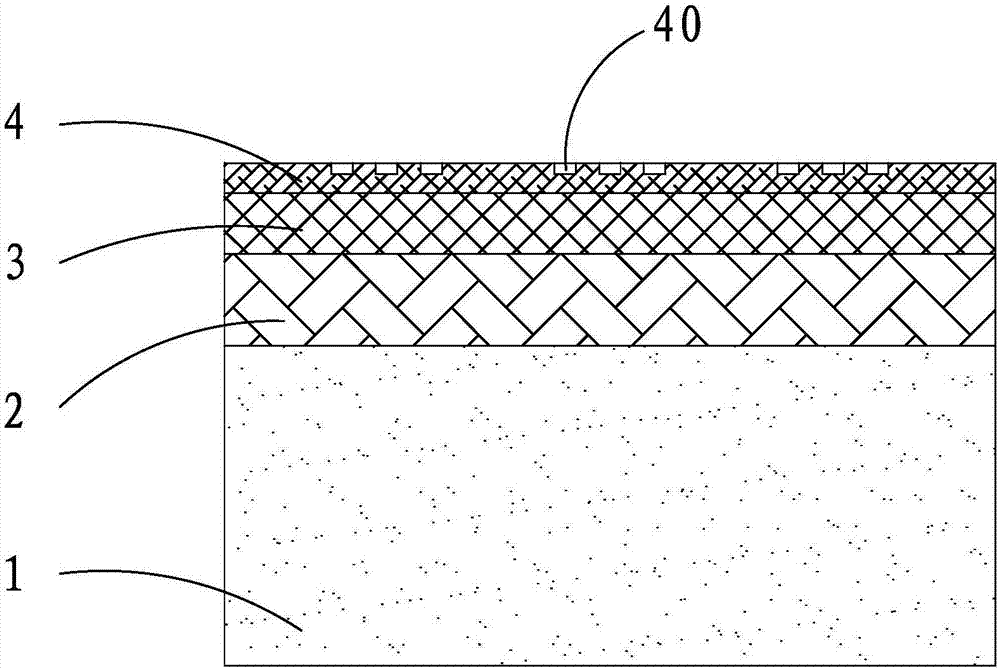

[0027] like Figure 5 Shown: a gallium nitride Schottky diode, including a substrate 1, an N+ gallium nitride layer 2 formed on the substrate 1, an N-gallium nitride layer 3 formed on the N+ gallium nitride layer 2 The mesa, the P-type GaN layer 4 with grooves 40 etched on the mesa of the N-GaN layer 3, the Schottky metal layer 5 formed on the P-GaN layer 4, and the N+GaN layer An ohmic metal layer 6 is formed on the 2, the Schottky metal layer 5 forms the anode of the diode, and the ohmic metal layer 6 forms the cathode of the diode.

[0028] The following describes in detail the fabrication method of the Gallium Nitride Schottky diode in this implementation, including the following steps:

[0029] (1), grow N+ gallium nitride layer 2 on sapphire, silicon or silicon carbide substrate 1, grow N-gallium nitride layer 3 on the surface of N+ gallium n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Growth thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com