Method for utilizing inert dust for preventing and controlling tobacco-plant pest-insects in cigarette factory

A kind of inert powder, the technology of cigarette factory, applied in the field of prevention and control of tobacco pests in cigarette factories, can solve the problems of dust pollution, pollution, difficulty in forming pest control effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

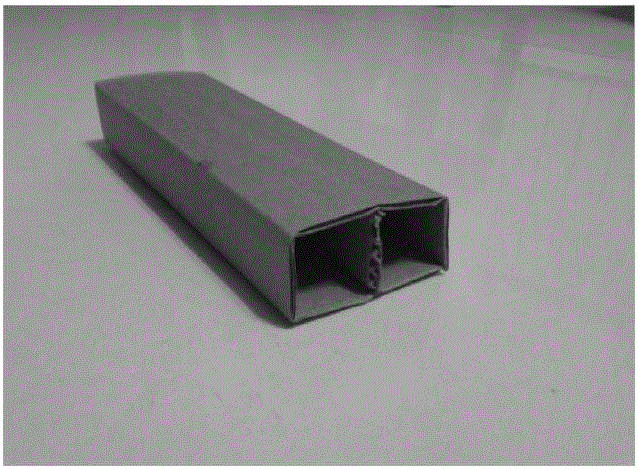

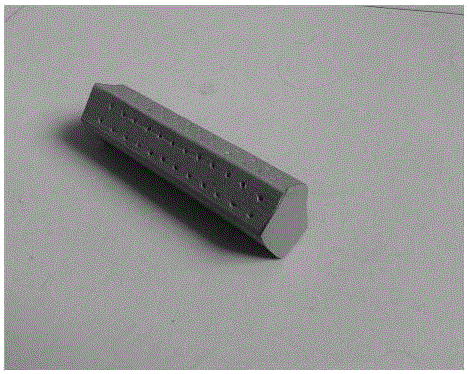

[0088] 1.1 A method of using inert powder to prevent and control tobacco pests in cigarette factories. In the places where tobacco beetles may appear, inhabit or cause damage in the cigarette factory production workshop, fixed-point release and recovery of solid carrier materials coated with inert powder; cigarette factory workshop Once the inner tobacco beetle is in contact with the inert powder insect repellant on the above-mentioned solid carrier material during crawling and shuttle activities, the inert powder will enter the intersegmental membrane of the pest body segment to absorb the lubricating fluid of the intersegmental membrane and wear the intersegmental membrane of the pest. The body shell or soft wax shell structure will also be pierced by sharp edges or thorns on the surface of the inert powder particles, causing it to gradually lose water and lose its ability to move and die.

[0089] According to 5㎎ / ㎝ 2 Coat and spray the inert powder on the solid carrier mate...

Embodiment 2

[0133] 2.1 A method of using inert powder to prevent and control tobacco pests in cigarette factories. In the places where tobacco beetles may appear, inhabit or cause damage in the cigarette factory production workshop, fixed-point release and recovery of solid carrier materials coated with inert powder; cigarette factory workshop Once the inner tobacco beetle is in contact with the inert powder insect repellant on the above-mentioned solid carrier material during crawling and shuttle activities, the inert powder will enter the intersegmental membrane of the pest body segment to absorb the lubricating fluid of the intersegmental membrane and wear the intersegmental membrane of the pest. The body shell or soft wax shell structure will also be pierced by sharp edges or thorns on the surface of the inert powder particles, causing it to gradually lose water and lose its ability to move and die. According to 5㎎ / ㎝ 2 Coat and spray the inert powder on the solid carrier material [dia...

Embodiment 3

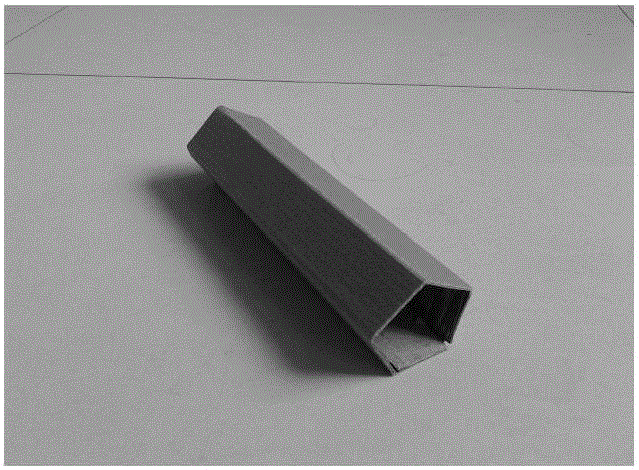

[0152] It is basically the same as Example 1-2; the difference is: a plastic, papery, non-woven or woven protective film bag is worn outside the solid carrier material coated and sprayed with inert powder, When in use, the protective cover bag can be torn off, or simply punched and perforated before being put into use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com