Method for separating and purifying dicarboxylic acid in DBA waste fluid

A binary organic acid, separation and purification technology, applied in the separation/purification of carboxylic acid compounds, liquid solution solvent extraction and other directions, can solve the problems of unsuitability for large-scale industrial production, high energy consumption, long reaction time, etc. The effect of mild conditions, good selectivity and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for separating and purifying binary organic acids in DBA waste liquid, comprising the following extraction step (I):

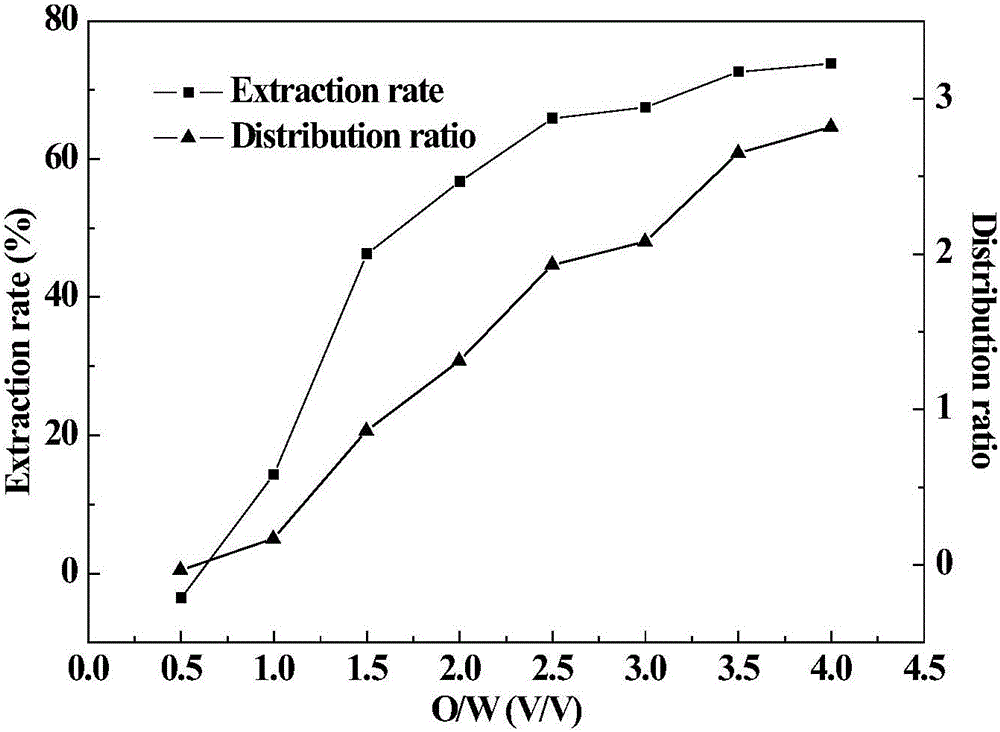

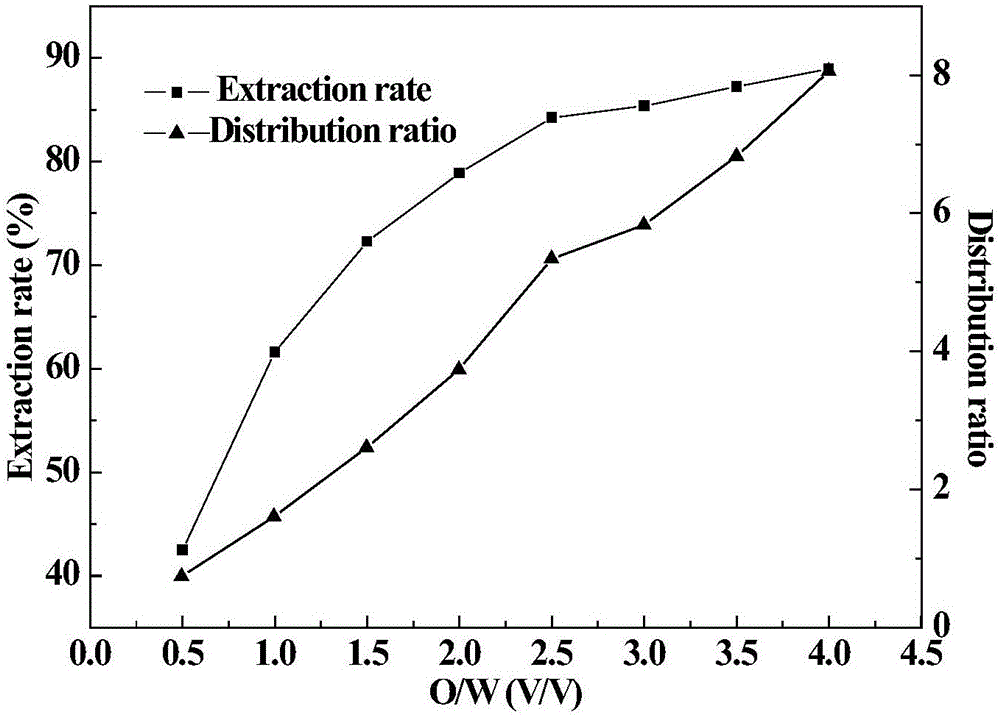

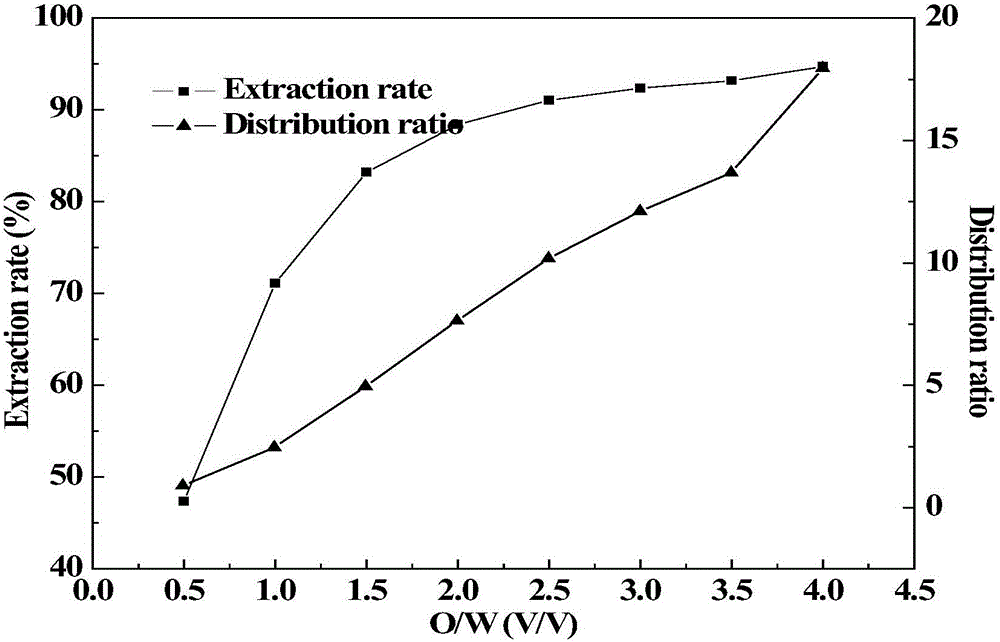

[0052] (i) Utilize secondary octanol to extract the binary organic acid in the DBA waste liquid, compare in the extraction step (compared in the present invention refers to the volume ratio of organic phase and aqueous phase, expresses with O / W, no longer Repeat one by one) are 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0 respectively, and the speed is 600r / min [when the speed is lower than 600r / min, the extraction rate and distribution ratio will increase with the increase of the speed ; When the rotation speed is higher than 600r / min, the extraction rate and distribution ratio are basically unchanged. This is because when the rotation speed is lower than 600r / min, as the rotation speed increases, the contact area between the aqueous phase and the organic phase increases, and the mass transfer is accelerated, resulting in an increase in the extracti...

Embodiment 2

[0057] The difference between this example and Example 1 is that the ratio is 2:1, the extraction time is 10s, 30s, 1min, 3min, 5min, and 7min, respectively, and the influence of extraction time on the extraction rate and distribution ratio is studied. The results are as follows image 3 , Figure 4 shown.

[0058] From image 3 , Figure 4 It can be seen that both the extraction rate and the distribution ratio increase with the increase of the extraction time. When the extraction time reaches 5 minutes, the extraction rate and the distribution ratio basically do not change with the increase of the extraction time, indicating that the extraction has reached equilibrium at this time. , so the best extraction reaction time in this experiment is 5min.

Embodiment 3

[0060] The difference between this embodiment and Example 1 is: the ratio is 2:1, the raw material liquid is extracted multiple times by secondary octanol, the volume of the loaded organic phase is accurately measured, and the impact of the number of extractions on the volume of the loaded organic phase is studied. The result Such as Figure 5 shown.

[0061] From Figure 5 It can be seen that with the increase of the number of extractions, the volume of the loaded organic phase first decreases and then basically remains the same. Because as the number of extractions increases, the loaded organic phase will remain on the container wall during the extraction process, and the number of extractions will increase, and the residual amount will also increase, resulting in a decrease in the volume of the organic phase. In order to reduce the residue of the loaded organic phase, the number of extractions should be reduced as much as possible, that is, the number of extraction stages...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com