Anti-bacterial medical protective film and preparation method thereof

A technology of protective film and antibacterial agent, applied in the field of antibacterial medical protective film and its preparation, can solve the problems of long disinfection time, waste of medical resources, increase of medical cost, etc., and achieve the effect of good killing effect and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail in conjunction with specific embodiments now.

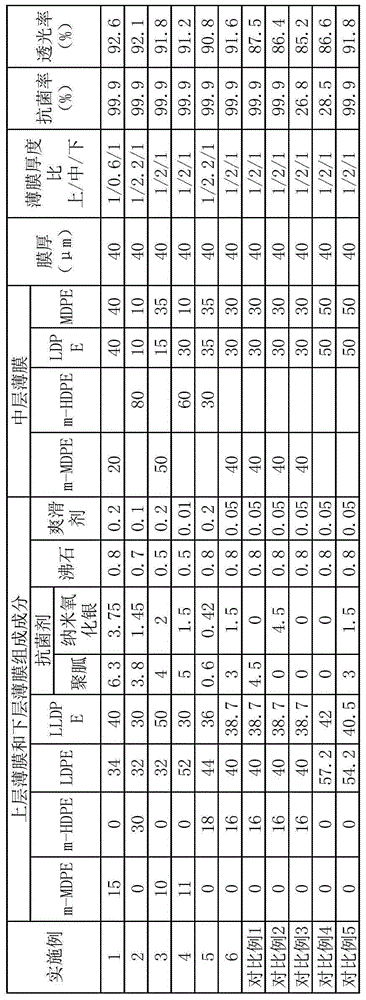

[0023] An antibacterial medical protective film, comprising an upper layer film, a middle layer film and a lower layer film adhered together in sequence, the composition of the upper layer film, the middle layer film and the lower layer film is shown in the following table:

[0024]

[0025] A preparation method for an antibacterial medical protective film, comprising the steps of:

[0026] 1) Mix the components of the upper layer film evenly according to the ratio of the above embodiment, and transfer them to the No. 1 and No. 3 extruder unit hoppers of the three-layer co-extrusion blow molding machine;

[0027] 2) Mix the components of the middle layer film evenly according to the proportions of the above-mentioned embodiments, and transfer them to the No. 2 extruder hopper of the three-layer co-extrusion blow molding machine;

[0028] 3) Simultaneously start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com