Ozone heterogeneous catalytic oxidation moving bed reactor and refractory wastewater treating method therefor

A moving bed reactor, heterogeneous catalysis technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve difficult operation, less research on ozone catalytic oxidation equipment, etc. problems, to achieve good water quality conditions, reduce secondary pollution, and reduce the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

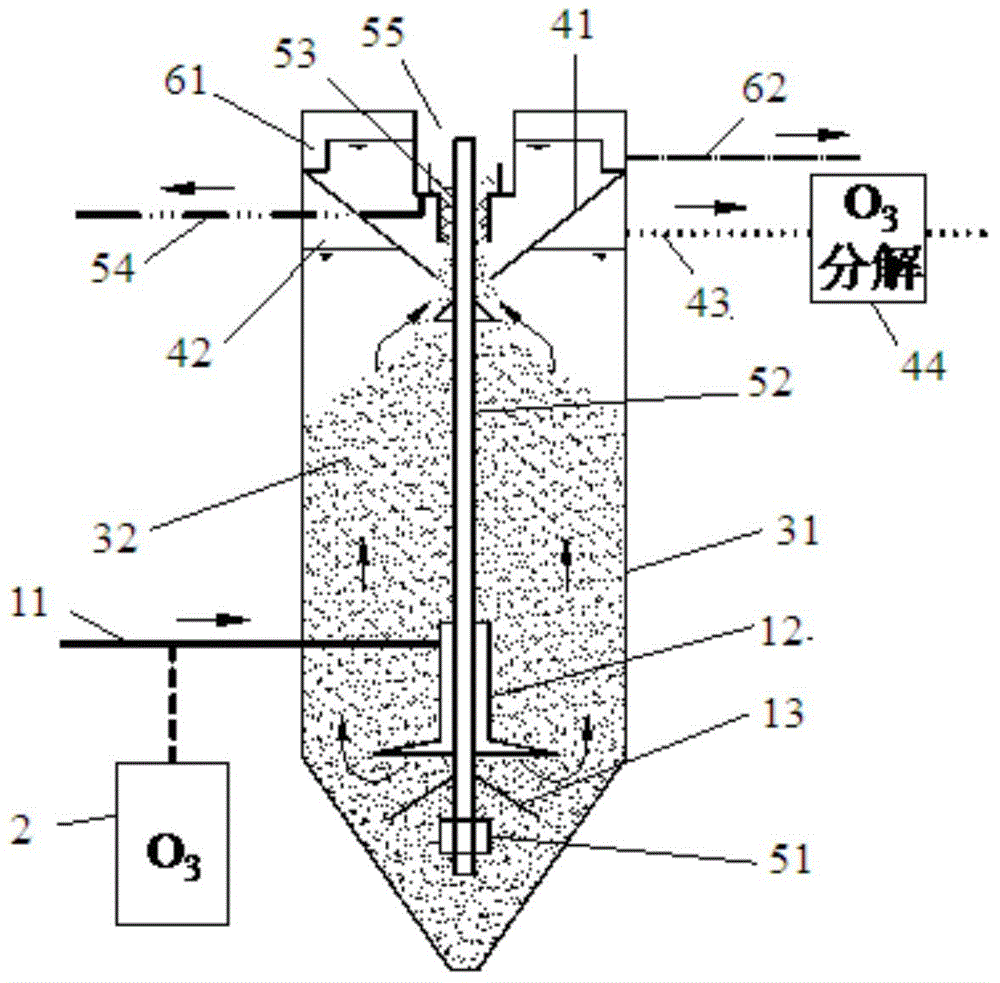

[0020] The ozone heterogeneous catalytic oxidation moving bed reactor designed by the present invention comprises a water inlet system, an ozone generating system 2, a catalytic oxidation reaction system, a gas recovery system, a catalyst cleaning system and a water outlet system; the catalytic oxidation reaction system includes a reaction Device 31 and catalyst 32; Contain air stripper 51, material lifting pipe 52, blanking port 53, washing waste water discharge pipe 54 and catalyst cleaning chamber 55 in the described catalyst cleaning system; Described catalyst cleaning chamber 55 is formed by reactor 31 The top center is concavely formed, and the central opening at the bottom forms a discharge port 53, and a washing waste water discharge pipe 54 passing through the reactor 31 is provided under the bottom left side; In the device 31, there are water distributor 12, baffle plate 13 and stripper 51 in sequence from top to bottom at its lower end; the water inlet system is comp...

Embodiment 2

[0022] The ozone heterogeneous catalytic oxidation moving bed reactor designed by the present invention comprises a water inlet system, an ozone generation system 2, a catalytic oxidation reaction system, a gas recovery system, a catalyst cleaning system and a water outlet system; the catalytic oxidation reaction system includes a reaction Device 31 and catalyst 32; Contain air stripper 51, material lifting pipe 52, drop opening 53, washing waste water discharge pipe 54 and catalyst cleaning chamber 55 in the described catalyst cleaning system; Described catalyst cleaning chamber 55 is formed by reactor 31 The top center is concavely formed, and the central opening at the bottom forms a discharge port 53, and a washing waste water discharge pipe 54 passing through the reactor 31 is provided under the bottom left side; In the device 31, there are water distributor 12, baffle plate 13 and stripper 51 in sequence from top to bottom at its lower end; the water inlet system is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com