Nano-zirconia ceramic LED lamp filament and manufacturing method thereof

A technology of nano-zirconia and LED filament, which is applied in the field of LED ceramic filament, can solve the problems of undiscovered patent literature reports, etc., and achieve the effects of easy control of the preparation process, good luminous effect, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

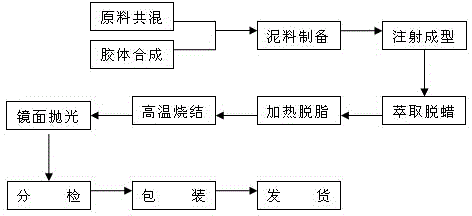

Method used

Image

Examples

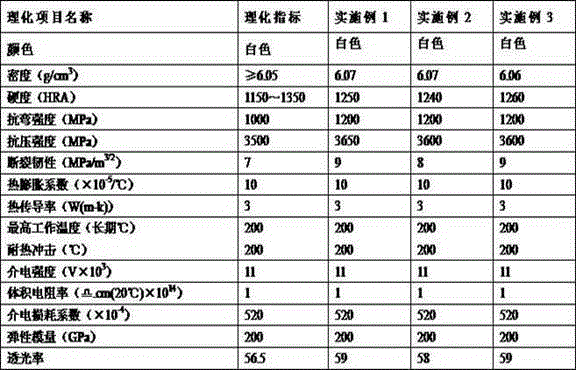

Embodiment 1

[0032] A method for manufacturing a nano-zirconia ceramic LED filament, comprising the steps of:

[0033] Step 1, raw material blending: 92 parts by mass of nano-zirconia and 8 parts of rare earth element oxides are uniformly mixed in a mixer to obtain a blend;

[0034] Step 2, preparing organic colloid: the organic colloid includes the following raw materials in parts by mass: 40 parts of paraffin, 20 parts of polyethylene, 20 parts of ethylene-vinyl acetate copolymer, 3 parts of Span 60, and 8 parts of oleic acid , according to the mass ratio, mix the raw materials, and melt at 200°C to obtain the organic colloid;

[0035] Step 3, mud preparation: According to the number of parts by mass, mix 60 parts of the organic colloid and 100 parts of the blend evenly, heat up to 180°C and mix for 160 minutes, then cool down to 50°C and continue stirring. Until the discharge particle size is not greater than 3mm, mud is obtained;

[0036] Step 4, injection molding: prepare the mud ma...

Embodiment 2

[0043] A method for manufacturing a nano-zirconia ceramic LED filament, comprising the steps of:

[0044] Step 1, raw material blending: 90 parts by mass of nano-zirconia and 5 parts of rare earth element oxides are uniformly mixed in a mixer to obtain a blend;

[0045] Step 2, preparing the organic colloid: the organic colloid includes the following raw materials in parts by mass: 15 parts of paraffin, 10 parts of polyethylene, 10 parts of ethylene-vinyl acetate copolymer, 1 part of Span 60, and 1 part of oleic acid , according to the mass ratio, mix the raw materials, and melt at 200°C to obtain the organic colloid;

[0046] Step 3, mud preparation: According to the number of parts by mass, mix 10 parts of the organic colloid and 100 parts of the blend evenly, heat up to 100°C and mix for 100 minutes, then cool down to 45°C and continue stirring. Until the discharge particle size is not greater than 3mm, mud is obtained;

[0047] Step 4, injection molding: the mud material o...

Embodiment 3

[0054] A method for manufacturing a nano-zirconia ceramic LED filament, comprising the steps of:

[0055] Step 1, raw material blending: 95 parts by mass of nano-zirconia and 10 parts of rare earth element oxides are uniformly mixed in a mixer to obtain a blend;

[0056] Step 2, preparing organic colloid: the organic colloid includes the following raw materials in parts by mass: 55 parts of paraffin, 30 parts of polyethylene, 30 parts of ethylene-vinyl acetate copolymer, 5 parts of Span 60, and 10 parts of oleic acid , according to the mass ratio, mix the raw materials, and melt at 210°C to obtain the organic colloid;

[0057] Step 3, mud preparation: According to the number of parts by mass, mix 80 parts of the organic colloid and 110 parts of the blend evenly, heat up to 200°C and mix for 200 minutes, then cool down to 55°C and continue stirring. Until the discharge particle size is not greater than 3mm, mud is obtained;

[0058] Step 4, injection molding: prepare the mud ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com