Acidic gas condensation-cooling process and device for vacuum potassium carbonate desulphuration

A vacuum potassium carbonate and acid gas technology, which is applied in the direction of steam condensation, combustible gas purification, combustible gas purification/transformation, etc., can solve the problem of increasing load, achieve the effect of small modification, simple device structure, and reduce system load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

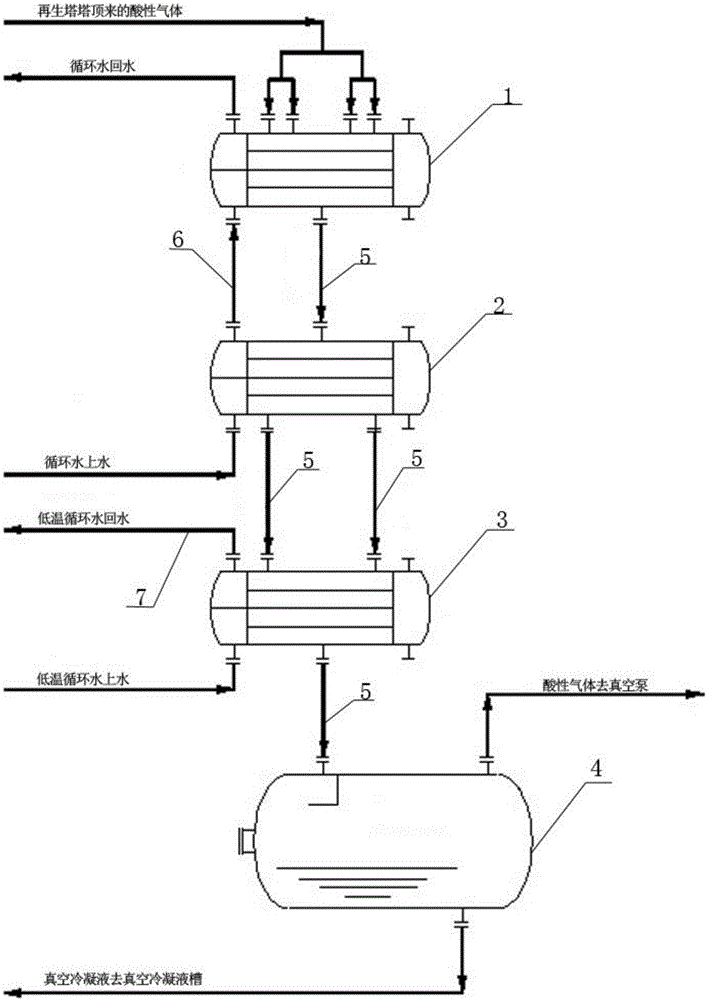

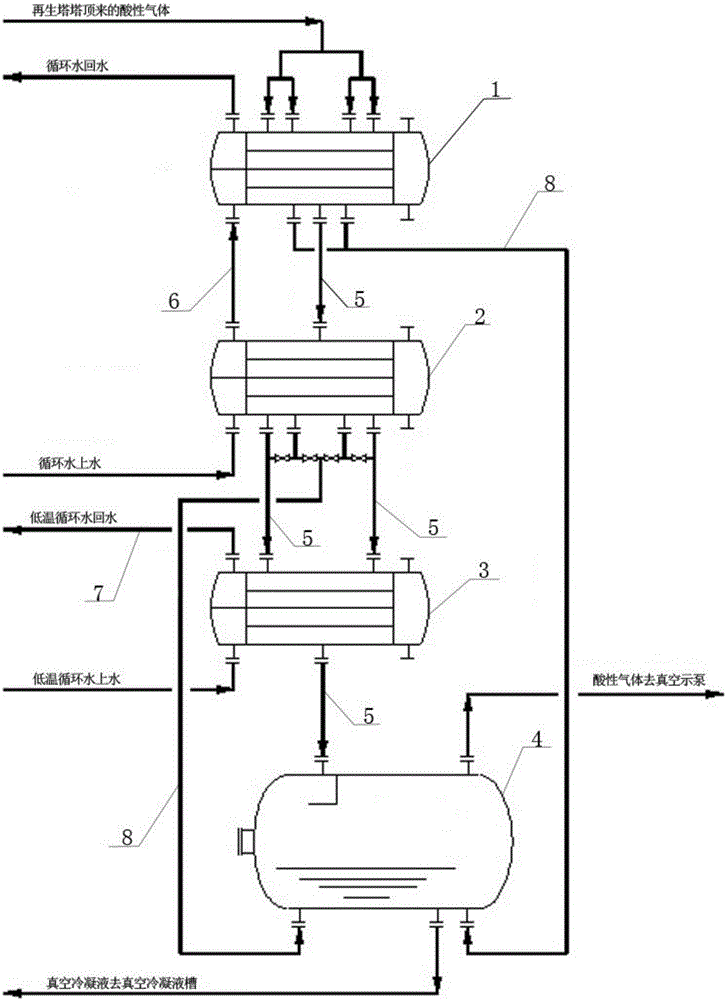

[0024] See figure 2 , is a schematic flow chart of the acid gas condensation cooling process described in the present invention. A vacuum potassium carbonate desulfurization gas condensation and cooling process described in the present invention, the acid gas escaped from the top of the regeneration tower, after two-stage condensation-cooling-gas-liquid separation, is pumped by a vacuum pump to the Claus unit or wet contact The legal acid unit recovers sulfur or produces sulfuric acid; in the acid vapor condensers 1 and 2 of each stage, the desulfurization liquid entrained by the acid gas and the condensed liquid are separated and sent directly to the gas-liquid separator 4.

[0025] The invention overcomes the pressure difference of equipment and pipelines through the water seal height.

[0026] A vacuum potassium carbonate desulfurization gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com